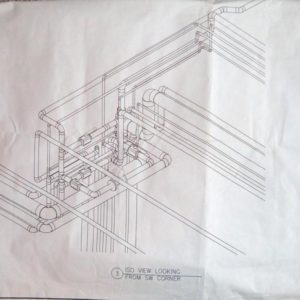

Just got handed this the other day & the detailer/engineer was just grinning ear to ear.

Sorry for the poor JPG, but I just switched to Vista ( not by choice) & having problems with my scanner.

This is a 8 pipe medical pipe system central distribution point, consisting of—-

6″ type “L” copper vacuum —- soft soldered

4″ type “K” copper (clean & capped) med air — sil-brazed

3″ type “K” copper (clean & capped) Building air — sil-brazed

2.5″ type “K” copper (clean & capped) Oxygen — sil-brazed

2.5″ type “K” copper (clean & capped) Lab air — sil-brazed

2″ type “K” copper (clean & capped) N2O — sil-brazed

1.5″ type “K” copper (clean & capped) Nitrogen — sil-brazed

1″ type “K” copper (clean & capped) Waste air purge — sil-brazed

“When politicians and journalists declare that the science of global warming is settled, they show a regrettable ignorance about how science works.†Nigel Calder, editor of New Scientist

Replies

Simple: Just use 1/2 pex. OK, OK bump it up to 3/4

Glad I could help

LOL

I think I need to go buy stock in acetylene plant---- we are blowin through a bunch“When politicians and journalists declare that the science of global warming is settled, they show a regrettable ignorance about how science works.” Nigel Calder, editor of New Scientist

I worked in a Navy shipyard and the standing bet between the Machinists and the Engineers was "If you can draw it we can make it"

Yeah, our old saying was " an engineers wildest dream is our worst nightmare"“When politicians and journalists declare that the science of global warming is settled, they show a regrettable ignorance about how science works.” Nigel Calder, editor of New Scientist

..." an engineers wildest dream is our worst nightmare."

When my husband got his first job (as a mechanical engineer) he had to wait for several months for a clearance. During that time, he read procedure manuals and designed a widget. Drawings for the widget were turned in just a couple of days before his clearance came through.

His first real day on the job, his boss's boss came through the office screaming, wanting to know which idiot had designed said widget. Husband dutifully raised his hand, and boss's boss chewed him out for a totally unworkable design, fired him, and stormed out.

Husband just about has his desk packed up when boss's boss comes in again and wants to know what he's doing. "You fired me." "You're not going anywhere until you fix that design!"

Husband worked there for fifteen years and ALWAYS got buy-in from the folks doing the work before releasing any design or procedure after that incident!!

(By the way, this was a mostly-Navy facility, so all the boss's boss verbiage has been heavily edited.)

Kathleen

Check these pictures out of a jib I framed when I went back I took these. They are horrible pictures but you can probably tell what all this is.

Framer (and Plumbill too), On the last two projects I supered I learned a whole new appreciation of the skills and brains it takes to do that type of work and make it look as great as it does when finished. Tip of the Hard Hat to both of you guys and all the others who do it.

I'd love to take credit for that plumbing but I didn't do it. I framed the house and went back and took the pictures. This plumber was the man as far as I could tell. He did very good work every where else also.Joe Carola

I live for exposed large mechanical systems, since about 90% of most plumbing is covered with walls , ceilings, & floors. It's nice to get to show off some work now & then.

I doubt I will build that system exactly like the ISO, but it will be close though---- since most of it will be sil-brazed when I take pics of it after it's finished it won't look all that pretty because of the heat used in brazing.“When politicians and journalists declare that the science of global warming is settled, they show a regrettable ignorance about how science works.” Nigel Calder, editor of New Scientist

plumbbill, The last two projects were wineries, all exposed water , air and glycol lines. Last one the plumber even had a kid follow him up at the end of the job wiping and polishing the fittings.Funny story about that plumberand the job.

He had a reputation of being the death or incarceration of several supers. Fortunatly for me I had a friend who was a tin knocker who knew him from other jobs they worked on together.

My freind gave me the low down , told me that the very first day I met him to just lay into him about schedules, quality , attitude etc. etc. Then just when the plumber was about to explode I was to tell tell him my friend had a message for him ....

"Gotcha" Caught the plumber so much by surprise he just burst out laughing and swore to get even with my tin knocker friend.

After that the plumber and I got along great , he was a good man and did fine work.

I take it that's around McMinville <sp>------ I have a problem with your local police around there----- somethin about standing in the median on his tiptoes to see if I was wearing my seatbelt or not :-)“When politicians and journalists declare that the science of global warming is settled, they show a regrettable ignorance about how science works.” Nigel Calder, editor of New Scientist

I am thinking you visited Carlton..lol Just up the road a piece. Nasty place ;-0

Can't remember exactly where it was, it was back in '97 I was on my honeymoon (3 yrs into the marriage) anyway I was haeding to Lincoln City to go to Salishan & was taking a left where there was a large median seperating a right turn lane & there was a cop standing in it---- I couldn't figure out what he was doing untill I made the turn where another cop was standing on the side pointing at me to pull over along with all the other WA license plates too. ;-)“When politicians and journalists declare that the science of global warming is settled, they show a regrettable ignorance about how science works.” Nigel Calder, editor of New Scientist

Bill, Only place that fits that description that I can think of is just north of McMinnville, Hwy 18 becomes a loop around town and Hwy 99 comes thru town.

McDougals Corner is what it is called around here. (If that is the right one it is one of the deadliest intersections in this state.) Hey could have been worse.. you didn't have California plates !

Hey, here is some pics of that cluster for ya.

View Image

View Image

View ImageIf you don't stand behind the troops, why don't you try standing in front of them. Bumper sticker

plumbbill,

Nice Job! I love the alignment of the piping. To see that is as nice as seeing well done carpentry finish work.

"Poor is not the person who has too little, but the person who craves more."...Seneca

That copper is almost mush, after heating most of it to 1600 degrees it gets a bit soft.

Here's a pic right behind the risers & one of our O-R branches.

View Image

I don't think I could fit anymore copper into this system, below pic.

View ImageIf you don't stand behind the troops, why don't you try standing in front of them. Bumper sticker

No, we don' hate you... we are just in awe that someone can take what is drawn and lay it out in an orderly fashion. I do have one issue though. I don't see any labelling of the pipes or at least I can't see any in the pictures?

I can appreciate the work involved with laying out and installation. I have worked with a master plumber that was an artist in his ability to install large complex systems for hospitals where you have gas, water, and vacuum lines all running side by side.

Gotta love Uni-strut.... best stuff ever.

Leland

LOL the "hate" was more tongue in cheek.

Labeling will be done on Monday.

If we pre label they will end up catching fire when we braze the copper.

Oh yeah I've been known to build anything & everything out of Unistrut, I still need to add about 4 pieces of Unistrut to that distribution center.If you don't stand behind the troops, why don't you try standing in front of them. Bumper sticker

Huuummm. Looks like my old screen saver. ;-)

Plumbbill, What do the different color bands on the copper risers indicate ?

Oxy? Hot or cold Water? And does the blackened sectioned of the pipes near the soldered (or is it brazed) joints damage or shorten the life of the piping? The winerys I have worked in have no where near that many pipes to configure. No oxy , mostly just H & C water, and then glycol lines for cooling/heating. Mentioning water reminds me I just had a job go down the drain (pun intended) because of lack of water for fire suppression and not enough in the budget for sprinklers. Now after waiting once again for 2 months for the job to get started I have no work and none in sight. Friggin lack of planning because the owners don't want to pay for it.

"Poor is not the person who has too little, but the person who craves more."...Seneca

Those are actually labels, yellow = medical air, green = O2, white = vacuum, blue = N2O, black = N

The vacuum is soldered & everything else is brazed, 1.5" & smaller I will usually use an A32 turbo tip to braze ( 1/2" diameter air acy mix) 2" to 3" I will use a #6 rosebud, 4" I will use the #6 rosebud + a 2" turbo weedburner to preheat.

It anneals the copper, but I haven't seen where it damages the copper or gives it a shorter life.

Speaking of fire protection, the sprinks decided to install a head above my prefab area----- yup popped that baby, fortunately it just had head pressure in it & wasn't tied into the fire main.If you don't stand behind the troops, why don't you try standing in front of them. Bumper sticker

Nice job! You oughtta see the Rube Goldberg plumbing nightmare in my basement. Previous owners decided to DIY some extra places for valves at the stationary tubs and a few aren't secured between the horizontal runs and the valves, which are 4' below. They could have just removed one section of hot and cold, installed whatever valves, nipples and unions were needed but apparently, they had some parts in stock.

"I cut this piece four times and it's still too short."

LOL, kinda sounds like my water service I had in a previous house I used to live in.

The water service was all one material until you got about 4' to the meter then it switched from poly to PVC with a Galv nipple to brass then to the copper pig tail------- I think they ran out of pipe & needed to get it hooked up.If you don't stand behind the troops, why don't you try standing in front of them. Bumper sticker

Looks like the typical situation you get into on a lot of commercial jobs; I don't think they hate you, they hate everyone. GREAT JOB!!

Yee HAW, medpipe.SamT

Praise the Corporation, for the Corporations' highest concern is the well being of the public.

Nice pics---- well what's in the pics anyways :-)

Always like square equal center systems.“When politicians and journalists declare that the science of global warming is settled, they show a regrettable ignorance about how science works.” Nigel Calder, editor of New Scientist

Nothing about the plumbing, of which I am woefully ignorant, but as for engineers, I find them often (ok, don't all the engineers get on me about that generalization, I'm sure some of you are human) to be getting back at the world for being the nerdy kid no one liked in school and college. It gives them power to see us regular folks squirm. I know, I've been at the other end of a sadistically complicated set of plans -- handed to me with a grin and a "just a few changes I added in after we spoke, hope you have money for this."

Well not exactly in this case, but I think a lot of them I deal with are big fans of Rube Goldberg.“When politicians and journalists declare that the science of global warming is settled, they show a regrettable ignorance about how science works.” Nigel Calder, editor of New Scientist

Hey guys. Plumbill is on the job! Remember the whining he did last job?

Let's give him that medgas cluster............

BWAHAHAHAHAHAHAHAHAHAHAHAHAHA.

LOL

There's almost some truth to that.

This is for a 10 story hospital addition to HARBORVIEW_MEDICAL_CENTER

I'm in charge of the distribution rack piping, & mechanical rooms, with some fill in work for the north wing remodel.

I'm running a 3 man crew right now 1 piping installer, 1 piping installer/ brazer & 1 brazer. As I was going over the prints for the "cluster" my whole crew walked off to their work areas---- I've never seen them so eager to get back to their job spots before. ;-)“When politicians and journalists declare that the science of global warming is settled, they show a regrettable ignorance about how science works.” Nigel Calder, editor of New Scientist

Only 3 guys? You must have a really gracious schedule. The project I'm on is a hospital addition for heart surgery. It's only a 6 story including the basment with each floor averaging about 36,000 sq. ft. It'll house 11 new O.R.s each containing all that fun med. gas stuff ran down the center of each room's surgical light/equip. boom that swings over the operating table. Than for patient space the addition will contain a total I think of some nearly 150 patient bays from recovery curtianed bays, to private ICU, and admitting rooms and at every location theres a bed is a wall plate with 6 outlets for all the NOS, VAC, CO2, and OXY. These plumbers are running a crew of 12-15 guys dedicated just to medical gas line install.

The best part of it is all these lines including the lines for a new chiller, pump condensate, high pressure steam, radiator line for a new generator all had to tie into the existing system which is of course on the complete other side of the hospital. Than being a hospital, function can not be interrupted in anyway and infection control is the first priority. So I spent 6wks on 4-10's from 5p.m.-3 a.m. supervising a crew of 5 plumbers to literally inch 2 - 10" steel grovelock pipe lines across the hospital, above the ceiling, and around all existing mechanical. These guys really earned their money even if they could at best get 8' of pipe in a night. The smaller lines went quicker but that 10" was something elese, there was literally one spot they had to use 8 fittings in 4', the insulator was real happy with that one. It's hard enough to mess around with that size pipe above ceiling and around existing equipment but the work areas were not closed down for construction. We had to move furniture around, set up carpet/floor protection, welding blankets, drape and seal fire resistant plastic for dust barriers, remove the ceiling in the area as need, set up negative air with hepas and smoke eaters, sometimes core block walls and fire stop open penetrations in the same night. Than before the end of every night we'd dismantle all temp. protection, replace ceilings and furniture, wipe clean/vac. all adjacent areas as if we were never there. Some nights we even got a bit of pipe in the air. We did such a good job of making sure every little nick nack on anybody's desk got put exactly back in it's place that we worked in one office for 2wks before anyone even had a clue work was being done in their office. That was only because a Dr. came back in after hours. She thought we where just setting up to paint and you should have seen her look of concern when she stuck around long enough to see the ceiling peeled open to reveal what we where up to and as one of the crew came around the corner with a 1000lbs. chunk of pipe on the tunnel buggy. You should have than seen my look as she said "Well just please be careful of these if you need to move them out of your way. (pointing to a bank of 4 computer screens, that apparently were not't just commuter screens.) The're expensive to replace at $8,000 a piece." We had finished hoisting the two needed sections directly above them the night before, and thank God hadn't dropped anything as we elected to just drape them in plastic for dust and otherwise just be careful.

We managed the whole chore with all our effort to never be seen and cursing out the engineers the whole time.

WHOA----- OK gotta hit that return button once in a while yer killin my eyes.

At this point I'm only in charge of the mains, there are other crews doing the wall med gas. We have 18 guys on the job right now--- should be about 22, but the hall is empty, so were making due.

Yeah I know what ya mean about putting pipe in on remodels, the north wing section will have a bunch of smaller distribution piping to put up above live post op rooms.

No offense, but Gruvlok¯ sucks----- well let me rephrase that a bit, I think it's ok for iron, but can't stand it for copper. We are using it for all the domestic water 3" & larger, Grinell gave to grooving machines to our company so we would use their system on this job. We are using Propress¯ for 90% of the domestic water 2.5" & smaller ( another system that sucks) well it goes together pretty fast, but the fittings are expensive & don't let it freeze, it will push the fittings right off the end of the pipe.

I dread when all the mains have to tie into the existing system on the main hospital. Vac & non clean systems are no biggie, but the pure systems get tricky on getting all the OXY out before we braze them.“When politicians and journalists declare that the science of global warming is settled, they show a regrettable ignorance about how science works.” Nigel Calder, editor of New Scientist

In case you are interested, some guys over at the Wall are finding a few leaks with propress and glycol.

Do any work with kitec on recirc lines?

I tell ya gycol will leak where nothing else will.

The guys were testing with water & there's no exterior walls up yet & we had one of those rare Seattle cold streaks come through & it pushed about 30 fittings apart.

Only experience I have with Kitec was helping my neighbor with his radiant heat system. To my knowledge pex-al-pex is not legal on domestic water systems, I'm not sure if Kitec makes reg pex pipe or not.

90% of my pex expierence is with Uponor¯ so I have to admit I'm pretty biased, unless it's about the material itself then I can produce more facts than opinions.“When politicians and journalists declare that the science of global warming is settled, they show a regrettable ignorance about how science works.” Nigel Calder, editor of New Scientist

Kitec makes both. P-a-P is certified for potable, and I agree, I prefer Wirsbo.

I'm sending you an e-mail.

OK I'll figure out how to get into my email----- I had to switch to Vista & my elcheapo dial up won't upgrade to Vista----- ordering clearewire today.

I looked up in my code book about pex-al-pex cause I remembered that it wasn't approved for domestic water inside the building------- at the end of the footnote it is approved for inside the building if maunfactured for domestic water---- I hate it when the same pipe is legal & illegal for the same purpose & you have to look for a certain # on the pipe.“When politicians and journalists declare that the science of global warming is settled, they show a regrettable ignorance about how science works.” Nigel Calder, editor of New Scientist

Ya, sorry. I just got going and didn't stop and it was late.

Just start brazing and that'll be sure to get rid of all the oxy in no time fast.

Funny, that's the same thing the fitters were saying about the Gruvlock and their not even using it for copper. just for those 2 10" iron chiller lines. Something about the clamps don't actually bottom out like the rigid to indicate being square and sealed. (I'm not actually a plumber, I work for the GC as labor Forman/safety dir./extra supervisor's set of eyes/site coordinator/infection control/laborer/and general b**ch)

Hey, I've got a question for you since you seem knowledgeable in these more commercial applications if you don't mind.

Since I don't make the big plumber money I snatch up every little piece of scrap copper I can that they over look. Sure they try to toss most stuff into a beer fund box but sorry to say they are still plumbers which are not known as the most diligent trade at clean up. So I may end up with a pocket full each day and it really does add up. They'll laugh at me for picking up 1/2" ring cut offs covered with solder and be like ya you can have that it's nuttin. I don't tell them I've got 2 55gal. drums in my garage of so far full of those nuttiness.

Ahhh sorry, there I go again. Anyway the question is what is the difference in type K nitrogenzied copper pipe and is it any more or less valuable as regular dom. water line copper scraped out as #1? Also interested in what purpose it serves in the process?

P.S.

Where on earth do you live that the hall is empty? Here in the capital of Mich. guys think nothing of driving 90min. one way for work. All the halls here are loaded where guys can sit 6mo.-12mo. Talked to one this week that said the hall only got them 68hrs. all last year.

Scrapped out, copper is copper.

#1 is clean wire & clean pipe & fittings with no solder on them & not too much discoloration.

#2 is darkened wire & pipe & just a little bit of solder here & there.

# 3 is pretty dirty pipe, wire with insulation still on it, & soldered fitting---IIRC

Nitrogenized pipe is a cleaning system used for medical gas pipe systems. Comes in type "L" & "K" with "K" being thicker, both are legal for med gas. The specs on this job called for "K".

I live in Tacoma Wa, work in Seattle & Bellevue mostly. We have 38 tower cranes up between the two right now & 8 jobs on hold waiting for cranes.

Over 3500 condo's going in in Bellevue in the next 8 yrs, huge boom going right now.“When politicians and journalists declare that the science of global warming is settled, they show a regrettable ignorance about how science works.” Nigel Calder, editor of New Scientist

Thanks, So being nitroginized is the cleaning the pipe manufacture does before plugging the ends and shiping to help ensure no debris or organics are in the pipe like for the oxy. that can combust when under presure. Thanks, makes sense. Wasn't sure if it was infused in the pipe or treated with for some other process.

Didnt I see that on The Three Stooges?

It should be easy, just picture Curly in the middle of it all.