PEX has made plumbing easier. The components are user-friendly for plumbers and leave water systems immediately ready for inspection. You won’t have to wait for glue joints to set up, there are no open flames, and there’s no flux to flush out of the system when you’re done. Options for connecting PEX plumbing are numerous, and using PEX to extend an existing copper plumbing system is not a problem.

Because PEX’s flexibility means fewer joints to connect, jobs are completed faster and with less chance of leaky joints. PEX resists the heat loss and scale buildup common to metal pipe.

PEX also has an advantage over alternative materials in cold weather because of its ability to expand rather than crack and break in freezing conditions. This flexibility also greatly reduces water hammer, the sound of metal pipe banging against a house’s framing. New adaptive fittings and brackets make PEX even easier to install.

There are two methods to connect PEX that don’t require a plumber’s license. (Expansion fittings require a plumber’s license in many parts of the country.) The push-fit method is great for quick repairs and requires no special tools other than a pipe cutter. For clamp-ring connections, I use a generic crimper, available at most plumbing-supply stores, and stainless-steel band clamps. When planning a PEX plumbing project, remember that only brass fittings (as opposed to plastic fittings, which are sometimes sold in home centers) are approved for underground or underslab use.

A fitting for every situation

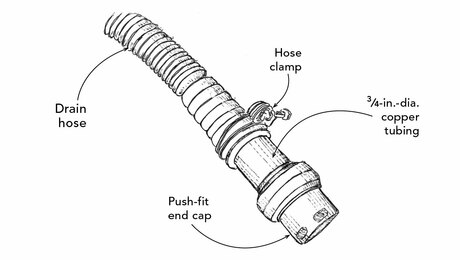

A push-fit fitting uses metal tines to hold the tubing, in this case PEX and copper, against an O-ring seal. The fittings are sized by the tubing’s outside diameter.

A clamp-ring connection connects PEX to existing metal pipe. PEX tubing is crimped onto the male end, and the female end is either soldered or threaded onto existing pipe.

In-line fittings are used to connect separate lengths of PEX tubing, to create a branch line, or to add a valve.

Push-fit fitting

1. Insert the support sleeve. This piece prevents the PEX tubing from collapsing and breaking the seal. Some manufacturers integrate the support sleeve into the fitting.

2. Insert PEX tubing. For a watertight seal, make sure that the PEX end you want to connect has a straight cut, that the tubing is clean, and that there are no scratches on the outside of the tubing.

3. Insert the copper pipe. The copper-pipe end does not require a support sleeve, but like the PEX, the exterior must be clean and smooth. Finally, to ensure a tight seal, give a final push to both pieces entering the connection. This type of fitting can also connect PEX to PEX.

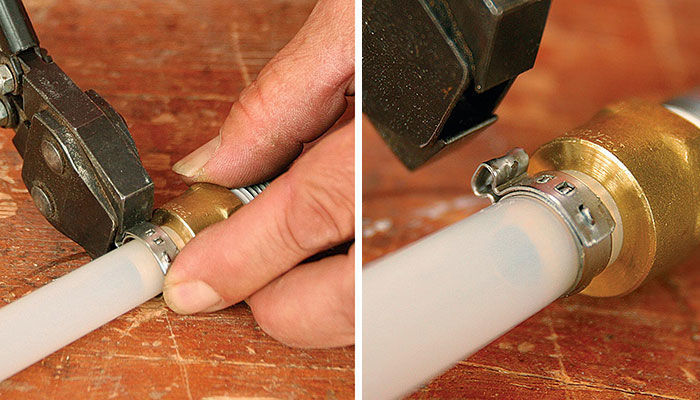

Clamp-ring connection

1. Fit the adapter to the existing pipe first. Whether the adapter fitting is threaded on galvanized pipe or soldered to copper, make the connection to the existing pipe first. Then slip the ring on the PEX tubing, and fit the PEX over the male end of the adapter.

2. Clamp the ring with a crimper. Position the ring over the middle of the adapter’s male end and tighten with a stainless-steel clamp-ring crimping tool. Proper placement ensures that the ring compresses the PEX tubing over the ribs for a watertight connection.

In-line support

Runs of PEX tubing with typical in-line PEX-to-PEX connections should be supported every 3 ft. However, at valve or branch joints, where extra weight could put stress on the line, it is a good idea to add a support clip next to the connection.

Bruce Norman is a licensed plumber in Portland, Ore.

Cost cutter

by John Ross

If you’re plumbing with PEX, you’ll want to spring for a tubing cutter rather than rely on a utility knife. However, when it comes to cutting PEX, almost any PVC cutter will do the job. The BrassCraft PVC cutter (www.brasscraft.com) has a ratcheting cutter action that can cut plastic, vinyl, or rubber tubing up to 15⁄8 in. in dia. I thought it was a little clumsy to use but still left a reasonably clean cut. If you look hard, you might be able to find a cutter for less online; you’ll definitely find some that cost more. For $12.95 at local home centers, though, the BrassCraft is worth the price and convenience.

–John Ross is an associate Web editor.

More on PEX connections:

Mastered in a Minute: Connect PEX video series

Connecting PEX Plumbing – A close look at the ever-expanding options for joining PEX plumbing.

Build Like a Pro: How to Make PEX Connections – Plumber Bruce Norman demonstrates how to connect PEX components with a push-fit fitting or a clamp ring. Watch now.

Three Designs for PEX Plumbing Systems — The pros and cons of trunk-and-branch, home-run manifold, and submanifold systems.

View Comments

Although we were able to easily add a radiator by using push-fit PEX connectors, the fittings are suspended over a dirt crawlspace, easy to inspect for leaks. Do codes allow such fittings to be used inside a wall, hidden from view?

You neglected to mention the copper ring swaged fittings. These require a special crimping tool for each size tubing , but make a very neat tight joint. Also hardware and big box stores sell plastic push on fittings. I've heard these arent approved for hot water, but I can't find guidance.

In the Midwest the copper ring swaged fittings over the outside of the PEX pipe to join fittings are the most popular at plbg wholesale houses and the Big Box Stores. The galv crimp ring shown in the blog I have not seen before.

Wirsbo AquaPex is also another choice of professional plumbers in the Midwest. Aquapex uses a special swedging tool inserted into the pipe to expand the PEX pipe's diameter to allow the fittings to be inserted into the pipe. A PEX sealing band is installed over the end of the tubing and then the special swedging tool is inserted into the pipe and both the pipe and seal are expanded. PEX pipe has a memory and after the fitting has been inserted into the pipe, the pipe will shrink back within a few seconds to it's original size and seal the fitting into the pipe.

The SharkBite fittings by Cash Acme shown in this Basic PEX connections blog by J-P Vellotti are popular, too. I like to use them where it is NOT safe for a torch to join copper pipe, too. The great thing about the SnarkBite fittings is that they can be removed if needed and reused.

I'm old fashion when it comes to piping and prefer the trunk & branch piping design. Pex is the prefer piping choice although I use copper to terminate through the walls to supply stop valves. I said I was old fashion...

LTB

I think it is only ethical to address the health effects of using pex tubing which hasn't been done here. The following link provides some convincing data that there are problems, including the presence of MTBE:

http://mikefox.com/jan17-2002.pdf

--Kenoli

Thanks for the info Kenoli. Has the PEX manufacturing process been updated / changed since this article? I think it is a good report but just one point of data.Is there any other research on this subject?

In an effort for balance to the previous post, a more recent (January 2009) California Environmental Impact Report on PEX including the NSF's conclusions on MTBE, et. al.

The linked PDF is very large.

http://www.documents.dgs.ca.gov/bsc/pex/2009/PEX%20FEIR_01-08-09.pdf

Excellent post, very useful! I'm a DIY, who is also very interested in environmental issues and found it just what I needed.

Incidentally, regarding the previous posts on MTBE, I'm writing from California, the last state in the USA to adopt the IRC and acceptance of PEX. It's a hot political issue here mostly because of a very strong plumbers' union lobby. It's refreshing to see concrete information from the EPA showing it is safe.

PEX is one of the easiest water distribution systems on the market, and when I am doing any type of plumbing DYI or renovations, it is the preferred means. Excellent article and great pictures!

Hullo! My first name is INDIRA. I am from Rockhill Furnace.

[url=http://glucophagereviews.over-blog.com/2013/11/can-you-buy-glucophage-online.html] glucophage for amenorrhea La Fontaine [/url] and buying glucophage online [url=http://offersglucophage.webs.com/] glucophage for cancer [/url] alcorkker: Also see: generic glucophage xr extended release La France and[url=http://reviewsglucophage.yolasite.com/buy-cheap-glucophage-online.php] glucophage cost without insurance La Grande [/url] Plus, a 2011 study from the University of Alberta found that eggs' antioxidant properties may help prevent cardiovascular disease and cancer.

P.S. Excuse me for choosing this resource to leave a speech for you about glucophage for hormones herstellten recycled arts