I am planning a shop addition on the top of my 1960 Colonial garage.

Background info = The garage is 2.5 bays wide x standard depth with a 3 season room off the back. Currently the roof is the only thing above these spaces. I live in Chicago, the garage is unheated. The house heat is radiant baseboard with a boiler. Standard AC with duct work.

Here’s what I have been thinking:

Building the addition with SIPs (Including the vaulted roof), radiant floor heating on top of an insulated floor made with engineered joists. The space will only have garage access to eliminate the chance of sawdust and finish smells entering the house. The cooling will be window or wall unit(s). Of course there will be windows and skylights. The second egress route will be a window. I will be upgrading the electrical service.

Where have I missed something? Do I want to run 3 phase for the shop machines? Will single phase git’r done?

Thanks

Discussion Forum

Discussion Forum

Up Next

Video Shorts

Featured Story

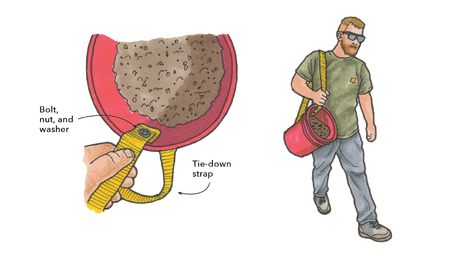

Add a strap for easy carrying and pouring when working with 5-gal. buckets.

Highlights

"I have learned so much thanks to the searchable articles on the FHB website. I can confidently say that I expect to be a life-long subscriber." - M.K.

Fine Homebuilding Magazine

- Home Group

- Antique Trader

- Arts & Crafts Homes

- Bank Note Reporter

- Cabin Life

- Cuisine at Home

- Fine Gardening

- Fine Woodworking

- Green Building Advisor

- Garden Gate

- Horticulture

- Keep Craft Alive

- Log Home Living

- Military Trader/Vehicles

- Numismatic News

- Numismaster

- Old Cars Weekly

- Old House Journal

- Period Homes

- Popular Woodworking

- Script

- ShopNotes

- Sports Collectors Digest

- Threads

- Timber Home Living

- Traditional Building

- Woodsmith

- World Coin News

- Writer's Digest

Replies

Are your shop machines already 3-phase?

Where are you? (filling out profile is helpful;SSN not required).

Building with SIPS sounds fine; nothing special about it except learning curve and basic design of the building.

But the 3 phase Q kind of threw me. Are you a commercial shop?

Tell us more.

Welcome to Breaktime!

I'd be surprised if you can get 3 phase powerat a reasonable cost. I use a rotary phase converter and it works fine.

I just built a house with SIP's and really liked the whole process. I found them very easy to work with.

Tom

Douglasville, GA

I'm in Chicago. I am not commercial, but the SawStop comes with a 3 phase option. Nothing 3 phase yet. To be honest is there a good reason to go 3p? I will not be ripping that much 12/4 stock. Can you give me a ballpark figure about the cost of putting it in there (% more than regular 110v and 220v)? My thinking is that I should wire the shop once and give myself as many options as possible. I can see myself buying used commercial size tools.

I thought briefly about 3phase but found the cost for the power company to upgrade the service to be more than I wanted to pay (buy two new transformers, new service line, etc.) plus they added a monthly surcharge for 3 phase. The advantage for 3 phase is that used heavy duty equipment is much cheaper than used single phase stuff approaching the same quality. Also, if I remember correctly, speed control is much easier with 3 phase. I have seen some rather large used 3 phase welder go for cheap when people were paying much more money for single phase units. Some of the fancier inverter welders seem to be available only in 3 phase. If you do a Google search on "rotary phase converters" you should see a couple of articles on how to construct your own phase converter using an old 3 phase motor (old 3 phase motors are generally availble for very little money). While the resulting converter doesn't provide exactly equal voltage on all three legs, the result is generally quite satisfactory to run power equipment. Of course, there are a number of companies that will sell you a commercial version of the same converter as well as some others who will sell you electronic converters which will keep all the legs equal, should you desire same.

Unless you are running a very large operation, 3 phase doesn't make sense. It is very expensive to have installed. I was quoted $15K + monthly charges. It may be cheaper if you have close industrial neighbors.

Older 3 phase equipment can be cheaper, but it is still older equipment. A rotary converter can be bought for less than $1K if you happen across a bunch of great 3 phase stuff. We had a large planer & used it for that, but still re-motored a big table saw to go to 1 phase (just $300 for a 3 horse motor for a Powermatic 66)

The advantage would be that 3 phase motors use less electricity overall, but smaller operations will never see the savings. My 1 phase table saw rips thick stock the same as a 3 phase would.

Treat every person you meet like you will know them the rest of your life - you just might!