As many of you know I am planning on building some cabinets, am still in the design stages and I’m new to the craft.

<!—-><!—-> <!—->

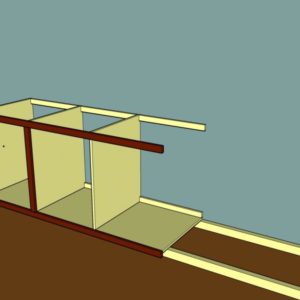

I ran some numbers up today and was surprised at the cost of the ply wood for the carcasses. All of the books I’ve read describe building cabinets modularly and then instilling them one at a time. I’m wondering if there is an alternative method where the cabinets are built in place as a single unit (see the attached image for an example).

<!—-> <!—->

This would have several advantages:

– would eliminate doubling the sides of each carcass

– could eliminate the back (using cleats structurally rather than backs), of course the wall would be visible through the carcass but I don’t mind that

– could use single pieces for face frame styles (which I think looks nicer)

<!—-> <!—->

A few questions:

– What are the negatives, why do no books seem to cover this style?

– Are there any books or articles that you can recommend that explain the construction process of this style?

Replies

No reason you can't do it that way. One small drawback you will run into is if you use pegs to support the shelves inside, the peg goes 1/2" into the wood. So with shelves at the same level in opposing cabinets, the pegs will need at least 1" thickness of wood or they will bumb into eachother.

Are you also building the doors?

--------------------------------------------------------

Cheap Tools at MyToolbox.net

See some of my work at AWorkOfWood.com

Edited 5/5/2008 11:36 pm by Ted W.

I still up in the air about building the doors. I'm leaning toward yes: I think it will be a fun project, there are only 14 doors and 7 drawers (in the current design) and I'll save a nice little bit of change. I don't have a router table so that obviously limits my design options but I like the clean, plain look of Shaker style doors with no rail/style profiles.

offset the rows of holes for the shelf pegs in the front/back direction by an inch and the interference issue goes away

i think they idea towards the modular is the ability to get the cabs into houses with tough access, (narrow stairs, narrow halls, tight turns, etc). If you can get your cab to where you want it, there should be no issue.

- Are there any books

View Image

http://www.amazon.com/Cabinetmaking-Procedures-Small-Shop-Commerical/dp/1892836114/ref=sr_1_1?ie=UTF8&s=books&qid=1210078893&sr=8-1

This book touches on your concept a little.

I have no problems with your approach either. Cabinets are built modularily because we rarely put them in our own house - they have to be transported.

I got my doors from Scherr's yesterday, they look perfect. Straight, flat and sanded for finiishing. They also came about a week early.

Joe

A lot of older houses had sight built cabinets similar to that.

Early this decade FHB had an article on building cabinets on sight. Don't remember the details.

My house has custom made cabinets that are sorta a hdybrid. Because of the shape, size, and layout the only continous run of cabinets are 60" of uppers that have 3 doors. They where made as a unit complete with continous backs and bottom, but only one piece of plywood between the section. On each end of those is a 45* corrner unit. It appears that all of the face frame was installed in the field and it apparear to be one unified unit around the kitchen.

There are 2 places that I am not sure if they where done in one piece or assembled in the field.

Next to on of the corner cabinets I have a full height upper and next to that the "over the range" cabinet and space for the hood. That cabinets then end at the stove. There is only one thickness of plywood between the full height and the over the range section.

On the left side (open) of the range the face frame comes down 18" over the counter (same as the full height uppers). One piece of plywood is exposed and it is flush with the outside of the face frame so the face frame extends more over the cabinet on that side. Then below the cabinet the face frame is padded out with 2 more pieces of plywood.

.

A-holes. Hey every group has to have one. And I have been elected to be the one. I should make that my tagline.

Once upon a time, all cabinets were "stick-built" on site. A highly skilled finish carpenter (e.g. my grandpa) would set up a work area, bring in his lumber, and the wood chips and shavings would fly as he cut and fit each piece - without any power tools!

Modular cabinets came about with the post WWII housing boom when mass production was necessary to meet the demand for cabinetry. Modules are easy to crank out, easy to ship, and can be assembled in various configurations. Add in some continuous pieces of trim and molding, and you get a nice set of cabs in a much shorter time frame.

One downside to modular cabs is the "filler panel" which becomes necessary to hide the fact that the modules seldom exactly fit in the available space. - lol

A couple of years ago, I modified some 1920's era cabinets in a Craftsman-style bungalow. I lost money on the job, but it was a blast figuring out how that long-ago carpenter had built them and making my modifications "fit" with his original work.

In the 70's I was a partner in a shop that built cabinets just as you are describing.

We could do a small kitchen with 3 base units and 3 uppers. (Maybe 16'-24' total base length.)

Only limitation was how heavy the units were and what access was like.

One beauty of that system is no filler strips are needed at the ends of cabinets, simple rabbits on the last stile at each end made for easy scribing for precise fits to the walls or adjoining cabinets.

Check out the attachment to see a built-in hutch which is sort of stick built. I build boxes for the bottom cabinets (3 of them) and one large face frame for the bases, but everything else had to be measured and cut a piece at a time. I also made the doors.

Not sure what may point is... just wanted to show off a little. But the concept is similar to what you're looking to do. --------------------------------------------------------

Cheap Tools at MyToolbox.netSee some of my work at AWorkOfWood.com

View Image

Click here for access to the Woodshed Tavern

Click here to visit the beginning of Breaktime

Ted

The built in looks good, well done. What ya got going out in front?

Just something laying there or is it some pattern in the floor.

Doug

Yea, really nice! So nice in fact I saved a copy of your picture to my "cabinet ideas" folder.

Thanks BigMish. Here's a couple of closeups of the glass door and shelf. The shelf is a actually a frame with a 1/4" rabbet to set the glass into. That way you see the painted wood shelf from the edge, but the light still goes through.

Also, I used 3/16" glass in the door to give it that stocky feel when opening and closing it, so it's doesn't feel light and flimsy.

--------------------------------------------------------

Cheap Tools at MyToolbox.netSee some of my work at AWorkOfWood.com

Edited 5/7/2008 9:47 am by Ted W.

Edited 5/7/2008 9:59 am by Ted W.

What you see is the old vinyle tile floor with some missing tiles. The floors gets carpeted over that. Actually, the floor is carpeted now and I'm currently re-laying a brick patio for the same client, so maybe I should get an up to date photo while I'm there. --------------------------------------------------------

Cheap Tools at MyToolbox.netSee some of my work at AWorkOfWood.com

My kitchen cabinets are like this. 60s era knotty pine. The plaster back wall is exposed.

A few things:

It's a little tougher to keep things organized since the cabinet sides force you to put things in front of doors. No cabinet walls means things migrate to unreachable places - like the corner in an L.

I'd suggest putting up walls/sides, at least, around the dishwasher and any cabinets that store cleaners (under the sink armory of bleach and ammonia). I am not so fortunate.

My plumbing runs inside the wall of the house. The waste pipe runs the length of my lower cabinets in front of the plaster. I don't like it but maybe there's some reason for it that you can use to your advantage.

The look is pretty clean with no fillers and you can maximize your space usage.

I'm not sure what the implications are for heavy countertops. We have a hideous pink speckled formica top with a metal edge band. Without cabinet walls or some other provision, I'm not sure if you could put granite or concrete countertops on.

Definitely seems like it should be cheaper.

Up here it's rare to see face frames on kitchens. For the European hardware to work, you need the double layer of ply so it makes sense to build them modularly. However, once they are built, I gang as many as I can together before hanging them.

your design doesn't show any base detail, one of the most important parts is the base, with modular each unit sits on its own base, so be sure to put plenty of support from the toe kick to the back, you'd be surprised how much weight will get stuffed in them ..

I was actually imagining placing the carcs (whether modular or built in) on a leveled platform of 2x4s (which I tried to represent in the illustration)