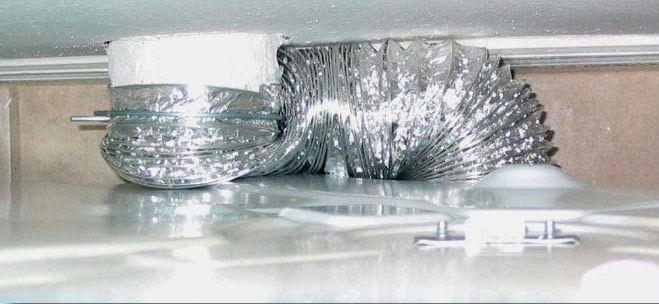

If you’ve ever installed a Clothes Dryer you know that the vent at the back is in jeopardy of being pinched off the second you push the unit back into place.

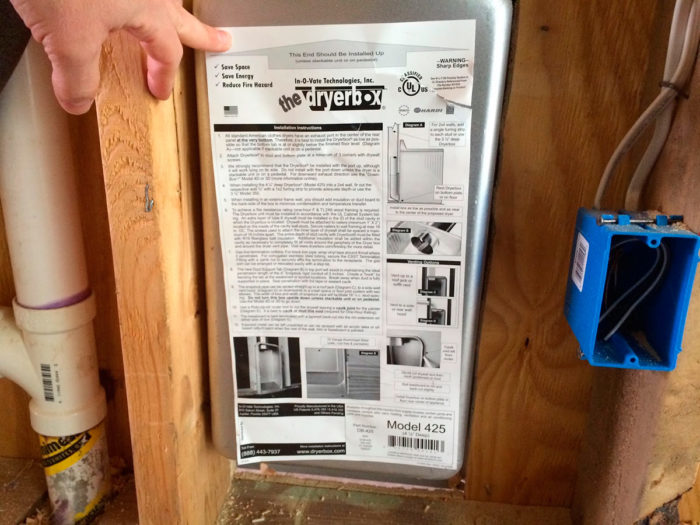

The simple way to eliminate this problem is by using a recessed box. The DryerBox Model 425 gives you a few inches back into your laundry room, and prevents the inevitable kink with an exhaust collar flush to the wall. I’ve been using these for about 10 years now, and finally when I was on the job site yesterday it hit me that not everyone has seen these before. Cheap but effective solution for this common problem.

These are super easy to install, run about $30, and are well worth the minimal price.

– Matt Risinger – Risinger Homes in Austin, TX

Risinger Homes is a custom builder and whole house remodeling contractor that specializes in Architect driven and fine craftsmanship work. We utilize an in-house carpentry staff and the latest building science research to build dramatically more efficient, healthy and durable homes.

View Comments

Great post Matt. Check out this automatic shut off valve for the washing machine supply. It's the Time Out Automatic Shut Off Valve by the Keeney Manufacturing Company - http://www.timeoutbykeeney.com/store It could be a great addition to your best practices approach to building and remodeling.

@edgarbrian: Thanks! I'll check out that auto valve. I typically use a combined hot/cold shut off valve that kills both with one down stroke. That way a client can kill both valves when going out of town easily. Your idea sounds even better! Don't forget the braided stainless hoses too. Best, Matt

@edgarbrian: I checked out that link. Looks like a good idea, but you'll need the right client to be willing to reset it each time they do a load. Here's a link to the valve I like to use.

http://amzn.to/1eomkZG

and the braided stainless hoses

http://amzn.to/1alqRcx

Any chance this can be retrofit an existing house without much trouble?

@ sethmeisterg : It's hard to say exactly, a retrofit could be very easy and straightforward. On the other hand, if your dry sits on an exterior wall it's more difficult as you'll need to use some rigid foam behind the Dryer Box and do some creative insulating. You might also verify your stud spacing in that bay you intend to install the box to ensure you have the room to recess this. It works best on an interior non-insulated wall. Good luck. Matt

These dryer connection boxes work very well. There are now several brands of similar design available at almost every home improvement store. Unfortunately, some homebuilders and their subs have no clue. We recently built a new home using a well known national home builder. I showed the construction supervisor a picture of the "Dryer Box". His response was, "No problem, we always use those." Really? A few days later the HVAC sub installed a cheap and useless 6" x 6" tin box with dryer exhaust duct jammed into it. After muttering a few unprintable words, I purchased the correct "Dryer Box" and installed myself on a Sunday afternoon before the drywall crew showed up. No one ever noticed and we have a nice unkinked connection between our dryer and the exhaust duct.

Hi Matt,

Great info on the recessed dryer connection. Quick question - why the plywood before the drywall? Is this code for a laundry room?

Thanks,

Joel

Hi Matt,

Why is plywood used over the framing before drywall. Is this a code requirement for laundry rooms.

Thanks,

Joel

@MAtt and @edgarbrian: Watts has an electronic valve that turns on the water when the washing machine is turned on, much like the switches that turn on a vacuum when your tool is turned on. Pricey, though. Don't know how to do the bity url that Matt used. Here is the long Amazon link:

http://www.amazon.com/Watts-EDP0004640-IntelliFlow-Automatic-Washing/dp/B00093DU5A/ref=pd_sim_sbs_hi_6

Thanks, edgarbrian. This has revealed a safety solution to me that I did not know existed.

Armin

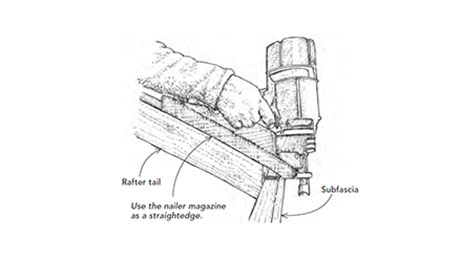

@noalarms The plywood is there as an inside shear wall as detailed from the engineer. That's unusual to see inside a house. Best, Matt

@PKB: Nice work! Way to take the ball and do it right! I love it! Matt

Matt,

Thank for the Dryer Box! Now for my next dryer concern. the house I am building is very tight. Goal is 1 ACH50 or less so I am concerned about the make up air and somehow connecting it to the dryer. I looked at the "FieldContols.com" vents and power vents but I could not determine if they were sealed fairly air tight and of course I would prefer some method that preheats the outside air with the inside air.

Do you have any ideas? seems that my gas water heater has both exhaust and intake air ... I need something for the Dryer massive air exhaust needs. At this point this is my only remaining large air leak 170-200. Thankfully I have no fireplaces backdraft concerns but I do have an attached Garage that I will be Closed-Cell spray foam sealing. If we were doing laundry while I was playing in the garage, each time I open the door it would see a 200 cfm intake. aarrgg ... :)

@ejkessler: I would look into the MAS-1 from Field Controls. That's a great unit. Another option might be a manual solution like a 4" hole in your Laundry wall with a damper you open for the hour your dryer is going. Close your laundry door and you've got a simple solution. I think Panasonic makes a "Passive Inlet" fresh air damper too, but that's a fancy version of a 4" duct with a guillotine style open/closer. Best to you, Matt

Interesting method for usre! But a little bit hard to achieve when you're renting and have restricted building rights to the place you live in. But I'd sooner complain to the landlord if appliances and things aren't working right if not I'll put my stuff back into the moving boxes and haul my bum out of there!

What equipment has changed since 2014?