Synopsis: The author explains the construction of a deck over a flat or low-slope roof. He covers both built-up roofing materials, which are layers of felt and asphalt, and elastomer materials in sheet and liquid form. The wider availability of EPDM roofing may have changed the picture slightly, but his methods of supporting deck components work just the same.

My first rooftop terrace introduced me to the built-up roofing business the hard way. I’d designed a small addition with a nearly flat roof, and I wanted to put a deck on top of it to take advantage of the summer weather, the view and the privacy. I called up the roofing contractors to find out how low the bids would go, and started dreaming of deck furniture.

As the roofers looked over the job, it became obvious that details and prices fluctuated wildly. One wanted insulation on top of the roof sheathing, another underneath; some wanted gravel in the flood coat, and others said gravel was unnecessary. To make matters worse, none of them would guarantee the roof because I wanted to cover part of it with a deck.

I finally got the job done, lost money and learned a lot. Since then I’ve done a lot of successful and more profitable installations, but I’ve never stopped keeping a keen eye out for good roof-terrace detailing.

Early decks

Years ago rooftop decks were called promenades or plazas, and were usually found atop fancy commercial buildings. They were covered with a hard and durable surface like quarry tile, laid over a built-up roofing membrane that kept out the water. This type of decking was occasionally used in high-end residential work, but it was too expensive for most ordinary construction.

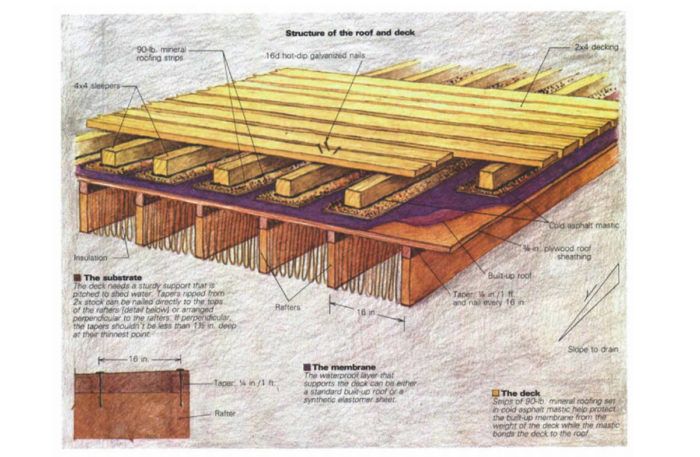

For a more economical solution, designers looked once again to commercial work, and they came up with the system generally used today — walkboards over a built-up roof. Walkboards, which are simply planks nailed to supports called sleepers, were originally used for scuttleways to reach roof-mounted mechanical equipment on factories, warehouses, office buildings and the like. The sleepers spread the traffic loads, and kept the fragile roofing plies from being crushed.

There are two types of roofing membranes suitable for supporting walkboards or rooftop decks: the tried-and-true bitumen (asphalt or coal-tar pitch) built-up roof, and a modern alternative, the elastomer roof. The built-up roof, with its many layers of hot-mopped felt, is perfect for use on low-pitched roofs because it forms a continuous membrane that keeps out wind-driven rain.

Elastomers are synthetic polymers with elastic or rubberlike qualities. They have gained wide acceptance in commercial work, despite their higher price tag, because they offer excellent flexibility, and resistance to weathering, fire, airborne chemicals, ultraviolet radiation and abrasions. They are also available in a variety of colors. Silicone, neoprene, Hypalon, acrylic and polyurethane rubber are all varieties of elastomers. Some are available in sheet form. Most can be applied as a liquid and finished with a trowel or paint roller. Toxic fumes can be a problem with these products, and you should be sure to pay special attention to instructions involving joining, mixing, curing times and using solvents. Because elastomers are still relatively new to the residential market, many roofers prefer to work with the traditional hot asphalt and gravel, and they continue to install the proven built-up roofs. What I will describe here is how to put a deck over a built-up roof so that the roof won’t leak.

For more drawings and details, click the View PDF button below: