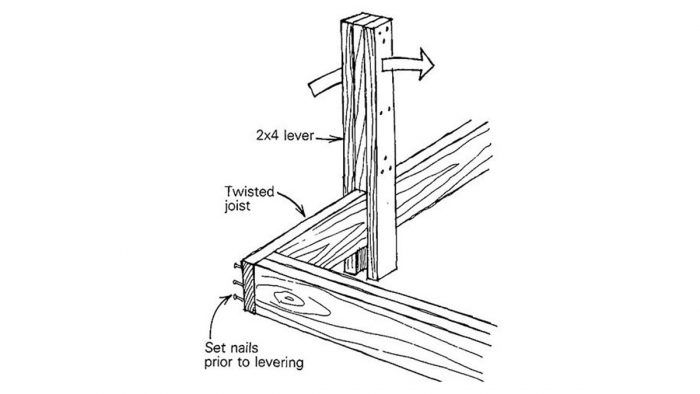

One of the first things we do on a new framing site is to build a “twister” to help straighten corkscrewed lumber. Our twisters are made of two 3-ft. 2x4s and one 2-ft. 2×4. As shown in the drawing, the long 2x4s sandwich the short one, creating a slot at one end. To use the twister, we nail the twisted piece of stock at one end. Then we slip the tool over the other end and move the twister until the stock comes flush with its nailing surface. The twister usually provides enough leverage that it only takes one hand, leaving the other free to swing a hammer or fire a nailer.

—Sean Sheehan, Basin, MT

Edited and illustrated by Charles Miller

From Fine Homebuilding #77

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Portable Wall Jack

Magoog Tall Stair Gauges

Guardian Fall Protection Pee Vee

View Comments

Why would you even consider using lumber that so twisted you need something like this to temporarily fix it? knowing it won't last.

Where do you get your lumber? I want to go there.

I miss "The Good Old Days" when "twisters" weren't needed.

You look at the end grain on a 2" x 4" nowadays, and you see 7 growth rings, as opposed to 2" x 4" from 30 years ago when you could count at least 30.

I have an old cut-off of a "real" 2' x 4" cypress that has at least 125 growth rings.

No wonder that we'll have 3-d printed houses made out of plastic dredged out the "Great Pacific Garbage Patch" one day soon.

https://www.homedepot.com/p/26-in-Board-Bender-Deck-Tool-93-310/203753633?g_store=&source=shoppingads&locale=en-US&&mtc=SHOPPING-CM-CML-GGL-D25T-025_001_HAND_TOOLS-NA-STANLEY-NA-SMART-3047250-NA-NA-NA-NBR-NA-NA-NA-HandTools_CO2&cm_mmc=SHOPPING-CM-CML-GGL-D25T-025_001_HAND_TOOLS-NA-STANLEY-NA-SMART-3047250-NA-NA-NA-NBR-NA-NA-NA-HandTools_CO2-71700000085130957-58700007246188681-92700065006063511&gclid=EAIaIQobChMI4aunysTK-wIVFVNyCh2zCAyyEAQYASABEgKcDvD_BwE&gclsrc=aw.ds