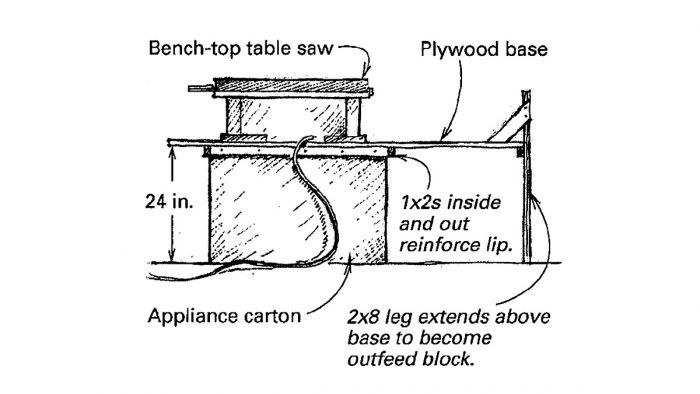

It often happens that I have a short, site-based job that requires a table saw. The saw I use for this type of work is a Makita 2708B portable table saw. It weighs a mere 38 lb., so it’s easy to move around. Its simultaneous advantage and drawback is that it doesn’t have a stand. The drawing shows how I improvise a saw stand from an appliance carton, which I can usually find on a job site.

To make the stand, I begin by cutting the box down to size with a sharp utility knife. About 24 in. is good. Then I reinforce the upper edges of the box with 1x2s screwed and glued both to inside and to outside surfaces.

My saw is affixed to a plywood base with a hole cut in it under the saw to allow sawdust to evacuate. I place the saw and its base atop the reinforced box and run some screws through the plywood into the 1x2s to hold everything together. As shown in the drawing, the plywood extends well beyond the back of the box, where it is held up by a 2×8 leg. This leg extends up to the height of the saw table so that it can support long offcuts.

When the job is done, I simply unscrew the plywood and cart the boxful of sawdust to the appropriate pile. The 1x2s serve as handles for moving the box. You can apply the same concept to all kinds of tools. But don’t let the box get too full of sawdust, or you might run the risk of overheating the tool or even causing a fire. Cut a hole in the side of the box for periodic sawdust emptying.

—Mark White, Kodiak, AK

Edited and Illustrated by Charles Miller

From Fine Homebuilding #105

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

DEWALT Impact Driver (DCF885)

Paslode Cordless Finish Nailer (IM250A)

Hitachi Pin Nailer (NP35A)

View Comments

I like the resourcefulness and dust collection but I don’t think an OSHA inspector would look too kindly on a cardboard box as a saw stand.