Making Bevel-Edge Laminate Countertops

With store-bought moldings and a router, you can give laminate counters the monolithic look of solid-surface material.

Synopsis: An experienced kitchen renovator explains how he uses readily available moldings to finish the edge of a laminate countertop. The bevel-edge moldings hide the dark lines that result when a strip of laminate is simply glued to the counter’s edge.

Every trade has its mysteries. People look at the finished product in awe and wonder how the heck the maker was able to do what he did. That was my reaction when I first saw a plastic-laminate countertop with a bevel edge. As is often the case, though, I found that those mysteries were actually simple techniques that any good carpenter can learn.

Although solid-surface countertops (i.e., Corian) get a lot of attention these days, plastic laminate remains the most popular countertop choice. The material costs much less than solid surface, and it comes in a far wider range of colors and patterns. However, most laminate countertops have a square outside edge that is susceptible to impact damage. And with light colors, the dark-brown underside of the top sheet of laminate shows up as an obvious stripe down the length of each edge. Bevel edges eliminate the dark line and are less likely than square edges to be damaged by impact. What’s more, eliminating the line by using a bevel gives the countertop a monolithic, solid-surface appearance. You can even change the countertop’s look by using a contrasting color of laminate on the bevel.

Bevel edges are actually precisely made moldings that you buy and then glue to a properly prepared countertop edge. You put them on after constructing the counter underlayment, and gluing and trimming the top sheet of laminate. (For an in-depth look at the whole topic, read my Taunton Press book Making Plastic Laminate Countertops.)

You have to buy the bevel moldings

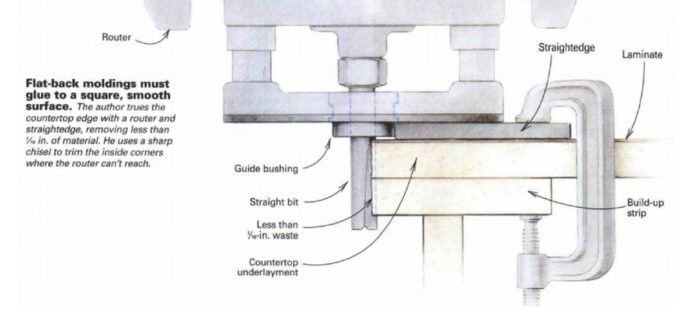

Bevel-edge moldings are made of plastic laminate glued to medium-density fiberboard (MDF). They come in two styles: flat back and tongued back. The flat-back molding is glued directly to a standard 1 1/2-in. thick countertop underlayment, and the tongued back fits into a groove routed in the edge of a 3/4-in. or thicker (up to 1 1/2-in.) underlayment. I’m partial to the tongued back because I think it’s stronger and easier to align; the precision work is done beforehand with a router, not during the panic of glue up.

I’ve found only two companies in the country that make bevel moldings. One company is Wilsonart International, and the other is Kuehn Bevel. Wilsonart’s bevel edges are available only with Wilsonart patterns and colors on them, but Kuehn’s edges can be had with any variety of laminate. For example, you could have Pionite laminate on the front of the molding, Nevamar on the bevel and Formica on the countertop.

For more photos, illustrations, and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Plate Level

Original Speed Square

100-ft. Tape Measure