Who Knew?

When I mentioned at the end of the Quick and Slick Crownmoulding blog post that I would show how to use SketchUp to figure compound miter angles for any crown moulding profile and any wall angle conditions I thought “how hard can it be?”. Well as it turns out, its much harder than expected. For tutorial purposes anyway. In hindsight, it turned out to be complicated enough that I’m not going to try to convince anyone that this is a practical way for figuring miter and bevel angles for cutting crown moulding. As you’ll see, it can be done, but its up to you to decide if its worth it. If you watch all five of the videos that follow I’m guessing you’ll learn some new stuff about using SketchUp (I sure did!) but just what you take away from the tutorial I’m not sure. As I said, who knew?

Crash Course in Photo Match: Part I

Assuming I haven’t talked you out of watching this tutorial yet, here goes. In an effort to keep a complex process simple (is that an oxymoron like “government intelligence?) this first video dives right into using the Photo Match pheature of SketchUp to “trace” a standard crown moulding profile from an actual moulding sample. After numerous attempts to photgraph the moulding sample I determined that the position shown in my photo is workable. Hint: keep the cut line on the back of the moulding parallel to the bottom of the veiwfinder on your camera. This helps to align the axes in Photo Match. Also, include reference marks and a dimension similar to those shown to “scale” your moulding model.

Crash Course in Photo Match: Part II

This video shows more of the process I used to “trace” the crown moulding profile. You’ll see how to establish a “drawing plane” to aid in tracing the lines and curves that make up the profile. Depending on your purpose for using these methods you can fine tune the profile outline to any level of accuracy. I’ve used this photo match process in a very detailed and accurate level to order custom knife profiles for a Williams & Hussey moulder. It can be done but I wouldn’t recommend it for standard modeling purposes.

Crash Course in Photo Match: Part III

Finally, this video shows the meaningful steps used to “capture” the moulding profile. Once the profile outline is completed it is separated and grouped for further maniupulation.

Set Up for Compound Miter Calculations Part I

This tutorial got more involved than I thought with the steps used to capture the profile using Photo Match. I hope at least some have stuck it out long enough to get to these last two steps where the main benefit is achieved: creating a visually accurate moulding profile for enhancing your SketchUp model and figuring compound miter angle settings. If I could have just started with an established moulding profile, these last two steps would have been the only necessary ones. For those who watched the Quick and Slick series, the steps shown in this 4th of 5 videos should be familiar.

Set Up for Compound Miter Calculations Part II: Saving the Best for Last

Now for the easy hard part. When I first set out to show how to figure the miter and bevel angles I was stumped. After some fussing around however, the steps shown in this last video proved to simplify the process. It just might be that the “take away” lesson is in this last video. Watch and see what you think…

And There You Have It

About all I have to offer viewers who have watched this entire tutorial is an “attaboy”, although you deserve much more recognition for your perseverance. And maybe you found a little help in building better 3D models as an additional reward.

Thanks for watching,

Matt

aka The Timber Tailor

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Reliable Crimp Connectors

8067 All-Weather Flashing Tape

Affordable IR Camera

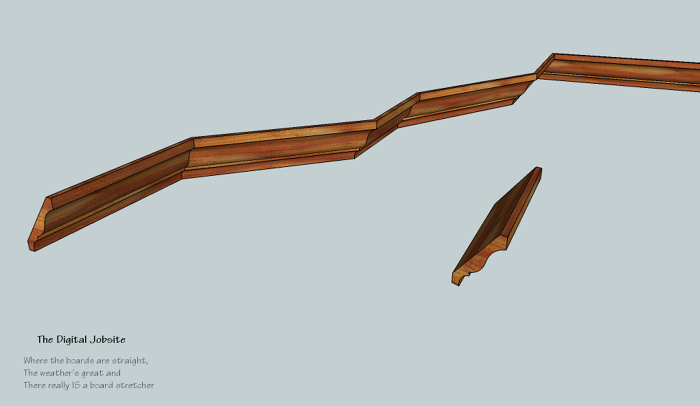

Measure crown moulding compound miter angles with SketchUp's Protractor tool. Or not.

View Comments

Hi Tim,

Haven't been around for awhile, but just watched your video presentation about how to solve compound mitre angles for crown molding. I'm impressed, thank-you! There is a pot of gold at the end of the rainbow! Can't wait to look back and see what else I missed.

Thanks Tim,

-CubeSquare

Matt, did I hear you say you commend us for watching the whole series through to the end ?? I think you may have made a mistake.....I commend YOU for making this series of tutorials ! It is very well done, it's surely a tedious task, but it is very helpful ! When you are mitering moldings laid flat on the miter saw, it is a pain figuring miter and bevel angles for other than a 90* corner. This is an excellent way to figure those angles to minimize the trial and error and tweaking. Thank you sir !! Don

Donluke,

Glad you found this helpful. It comes to mind that the thorough process as shown in the tutorial could be streamlined by avoiding the part of tracing the curved profile with Photo Match. If you just measure the straight surfaces that represent the back of a particular moulding and use a straight line for the face, the resulting compound miter angles would be the same. Let me know if I'm making sense here. If not I'll do another tutorial so visitors can visualize it.

Thanks for stopping by The Digital Jobsite.