If you want to take your finish carpentry to the next level, you’ll need to master the block plane, the secret behind fast, accurate scribes on stain-grade trim and the quickest way to ease edges, adjust inset cabinet doors, and tweak miters.

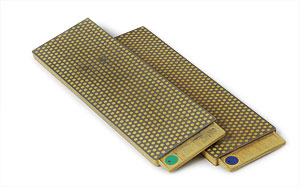

The first step in becoming proficient with this important tool is learning how to sharpen it. I like diamond stones for sharpening because they’re durable. The downside is that they’re expensive. Each of the double-sided stones sells for about $80, but they should be a one-time purchase.

Fine diamond stones can produce an edge sharp enough for most work, but for a plane that’s a joy to use, you’ll want to hone with something finer. I use a Norton 4000/8000 combination-grit water stone, which produces a supersharp edge with only a little more effort.

Water stones will eventually dish out in the center, so you’ll need to flatten them occasionally by running them against the most abrasive diamond stone. When the water stone has a uniform color and appearance, you can stop flattening.

If you can’t afford diamond stones, you can use sandpaper glued with 3M Super 77 spray adhesive to pieces of float glass or granite countertop. Compared to the diamond stones, the sandpaper may seem like a bargain, but the finer grits (available online) cost between $2 and $3 per sheet.

Flatten the sole

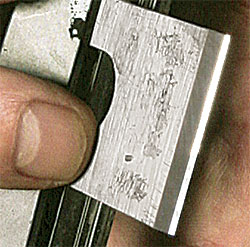

One often-overlooked step in preparing a new plane is flattening the sole and the back of the blade (also known as the iron). Fortunately, you have to do this only once. I flatten a plane bottom by running it back and forth over the 60-micron diamond-stone surface. I stop when the bottom has uniform striations across its length and width. There’s no need to polish the flattened sole further, but a little paste wax will prevent rust and help the plane to glide.

Flatten the blade

With the sole now flat, I flatten the back of the blade. Holding it flat on the stone, I move it sideways over the four diamond-stone surfaces, looking for uniform scratch marks before switching to the next-higher grit. The 9-micron diamond stone is fine for most work, but if you want a really sharp edge, you’ll want to use a water stone, too.

I use the 4000-grit side of my water stone first, then the 8000-grit side. Keep the water stone wet to create an abrasive slurry.

Hone the bevel

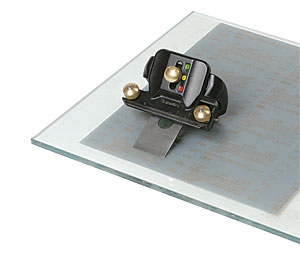

Block-plane blades are sharpened at a 25° angle. I’ve never been able to master manually guiding the blade at a consistent angle, so I use a honing guide to keep the blade in the proper position. With the blade in the guide, I work through the series of diamond stones and then both sides of the water stone. When honing on the water stones, I adjust the guide’s eccentric roller so that the mark on the adjustment knob is in the six-o’clock position to produce a microbevel. This makes final honing go faster because you’re sharpening less of the blade.

As you work through the grits, you’ll feel a burr developing on the back of the blade. Leave it alone until you’re done honing. Then remove the burr by holding the blade flat (bevel side up) and gently moving the blade from side to side.

Once all this is done, reassemble the plane, and take a test pass to make sure it is creating an even shaving. If the plane is taking more stock on one side, use the lateral adjustment lever to true the blade.

Step by step

1. Flatten the bottom. After removing the blade, flatten the plane bottom with a 60-micron diamond stone or 220-grit sandpaper. Keep the abrasive wet, and run the plane back and forth until uniform scratch marks are covering the bottom.

2. Flatten the blade. With the bevel side up, move the blade back and forth sideways until uniform striations cover at least the bottom quarter of the bevel end. Move to the next-finer grit when the blade gets a uniform polish.

3. Set up the guide. Set the guide’s registration jig at 25°, and put it on the honing guide. Tighten the two screws on the guide’s blade clamp a little at a time until the blade is held securely. Then remove the jig.

4. Check the roller. With the jig on the stone, rotate the guide’s eccentric roller until the bevel sits flat on the stone. The roller is designed so that you can set the blade for a microbevel during final honing. A microbevel makes the final sharpening go faster.

5. Work through the grits. Using moderate downward pressure, move the guide back and forth until the bevel gets a uniform striated appearance. Do the same with each grit in turn. Rotate the diamond stones often so that they wear evenly.

6. Make a microbevel. Use plenty of water as you hone, and wipe the blade when you switch grits. Once you’ve worked through the diamond stones, switch to the water stone. Adjust the guide’s roller so that only the leading edge is touching. Start with the 4000-grit side, then move to the 8000-grit side.

7. Remove the burr. Place the blade flat on the 8000-grit stone with the back side down. Use a gentle side-to-side motion to remove the burr. Wipe the blade, and then put it back in the plane with the bevel facing up.

1

8. Take a pass. Adjust the blade for a thin shaving, and make a test pass on a softwood board. Make lateral adjustments until the blade takes an even shaving the full width of the blade. Adjust the throat so that it’s as close to the blade as possible without clogging

Sharpening tool kit

While expensive, diamond and water stones should be a one-time purchase. If funds are tight, you can use sandpaper bonded to a piece of float glass.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Handy Heat Gun

Affordable IR Camera

8067 All-Weather Flashing Tape