Airtight Corner for a Variety of Cladding Types

See how the team at FHB House Kansas assembles a solid corner with backing on both sides for consistent nailing on multiple types of siding.

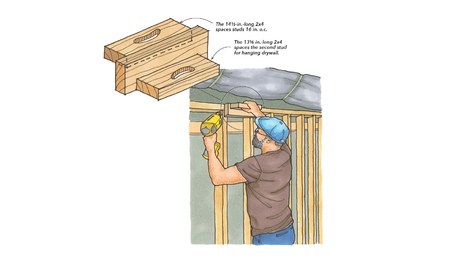

Today at FHB House Kansas we are looking at our wall assembly. Our walls are 2×6, framed 24 in. on center, and we used ZIP System Insulated R-Sheathing on the exterior to establish a thermal break—and it starts us off with R-6 for thermal resistance. In the cavities, we insulated with Rockwool Comfortbatt R-23. With sheathing and insulation combined, this puts us around an R-30 wall. Having studs every 24 in. and header material will create some thermal bridging in places, but by having the R-Sheathing on the exterior, we’re really knocking out that bridge at the outside.

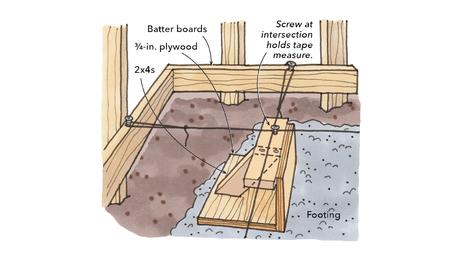

Because we don’t have the same type of cladding all the way around the house—we have brick across the front, some board and batten, and we might have corner boards that we need to trim—we like to go ahead and achieve a solid corner with backing on both sides. It might be common practice with some builders to butt one sheet into the next and leave a gap at the corner, but we like to cut back an inch of the polyisocyanurate backing on the ZIP R-Sheathing. This allows us to mate the other sheet together to create solid backing of OSB to OSB.

One of the main reasons we like to use a cantilevered sill is so that we can make a taped connection without any fancy primers. No crazy material is required that would be complicated or slow to work with, or difficult to source. We are using the same ZIP System Flashing Tape that we used on the sheathing seams, now at the bottom of the panel right onto the mudsill, because we’ve already established an air-seal below that mudsill. Taping the mudsill to the wall gives us air-control continuity from the foundation up.

Committing to a full system and following the instructions and guidelines provided will result in an airtight house that will perform well, be more comfortable to live in, and overall, provide a healthier environment.

It’s all about continuity.

RELATED STORIES