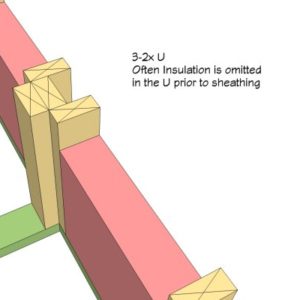

How do you frame your T-intersections where a wall intersects an exterior wall at or between studs?

The old method of 3 2xs nailed in a U-shape makes it a challenge to remember to insulate it prior to sheathing the exterior. I know quite a few that don’t have the prescribed insulation and there are more that I’m suspicious about.

View Image

Do you use drywall clips? Who’s your source?

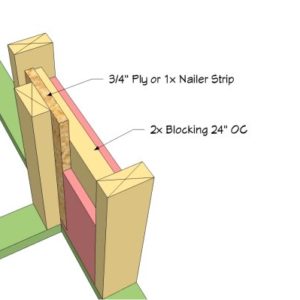

Do you use a 1x or plywood nailed to the last stud of the intersecting wall? Was flipping through a construction book (by F. Ching) and came across this example but I’m not sure you really need the 2x blocking. I’ve used 2x8s in the past but using ply would allow you to use scraps from the subfloor.

View Image

Code is kinda vague as I see it. Whatever you can get your BI to agree with and have something to support your DW you’re going to be OK.

Replies

I turn a 2x6 in the exterior wall that centers on the intersecting 2x4 wall. You can easily run insulation behind it, and there is just enough to catch SR

Welcome to the

Taunton University of Knowledge FHB Campus at Breaktime.

where ...

Excellence is its own reward!

That's sim to my 2x8 but cheaper material-wise and labour wise since 2x6s are already on hand and in hand.

View Image

I always did like your firs pic, except there would be 3 blocks about a foot long in the outwall, instead of full length..they did get insulated where I was. We had foam on site from sheathing with foilpolyiso, so rips of that went in.

Spheramid Enterprises Architectural Woodworks

Repairs, Remodeling, Restorations

They kill Prophets, for Profits.

What Piffin said.

Andy

"Never try to teach a pig to sing. It wastes your time and annoys the pig." Robert A. Heinlein (or maybe Mark Twain)

"Get off your dead #### and on your dying feet." Mom

"Everything not forbidden is compulsory." T.H. White, The Once and Future King

Commercial rockers hold the intersecting wall plate back a bit, and just set the end stud into the bay --the channels will hold it in place.

That way they can rock the long wall straight through, then slide that last stud tight to the through-wall.

I've never done that, and I don't like running crown and base without adequate blocking, so I'd still want to throw something in...

Gotta be more airtight, though, as well as being faster and easier.

AitchKay

we do like piffen said....

or , if it's a mooney wall, the mooney runs thru the intersectionMike Hussein Smith Rhode Island : Design / Build / Repair / Restore

We run a 2x6 block on edge top and bottom, then a few 2x4s...http://www.tvwsolar.com

I went down to the lobby

To make a small call out.

A pretty dancing girl was there,

And she began to shout,

"Go on back to see the gypsy.

He can move you from the rear,

Drive you from your fear,

Bring you through the mirror.

He did it in Las Vegas,

And he can do it here."

I like that, that's pretty simple.

Plenty of good comments on the insulation already. I just wanna say, re your graphics.... you BAD!

In the Mooney the DW runs right through the intersecting interior wall? I missed that reading the Mooney Wall threads.

View Image

sometimes yes, sometimes no

View Image

the way i'd prefer now is those 4 studs backing the intersection would just be left out

the partition gets nailed to the mooney, the sheetrock doesn't go thru, it butts to the partition and gets backed by the mooney every 16"Mike Hussein Smith Rhode Island : Design / Build / Repair / Restore

Just like that drawing, but lose the four studs, that's my vote for the Mooney version.AitchKay

I like these for outside corners... rips from Advantech drops from decking, screwed to the end stud after erection.http://www.tvwsolar.com

I went down to the lobby

To make a small call out.

A pretty dancing girl was there,

And she began to shout,

"Go on back to see the gypsy.

He can move you from the rear,

Drive you from your fear,

Bring you through the mirror.

He did it in Las Vegas,

And he can do it here."

Hey cool! You're leading into the original question I was working on but never posted, got side tracked with the T's instead.

I'm a bit slower than I usually am so figure when things start spinning back up maybe I can be smarter? Well, maybe not smarter but maybe a new trick or two.

If you were doing new construction, you would frame the intersecting interior partitions AFTER the exterior walls are framed and standing? How would you intersect the top plates where the interior partitions intersect with the exterior wall?

Always having used the intersecting interior partitions (when available) as braces to hold the exterior walls straight, I'm thinking I would need to do some extra bracing as opposed to running a diagonal down one of those intersecting interior partitions.

Thems three studs with three cut-off blocks. Stop wasting materials!

sometimes yes, sometimes no

View Image

the way i'd prefer now is those 4 studs backing the intersection would just be left out

the partition gets nailed to the mooney, the sheetrock doesn't go thru, it butts to the partition and gets backed by the mooney every 16"

Eric, when I drew the Moony wall interpretation I was figuring it was a retro and the original stud framing would've been left intact otherwise you get into issues with siding. Pulling them never installing them would be better/reduce the thermal bridging.

That answers some qustions that've always lingered about why I had to glue some trim in the past after about 100 nails. :)

I wonder if we could make that work in res framing but the trim install is still going to be an issue.

View Image

Would trim be an issue if you knew ahead of time? Since you knew there wasn't wood behind one side you could run that side first a use the other side to hold it in.

Does that make sense? Kind like the drywall, but reversed.

I know that a trim carpenter is going to want wood everywhere and then some more.

But if you were framing it and trimming it you could plan ahead.

Edited 3/27/2009 5:02 pm ET by popawheelie

I don't know commercial from Gnome housing, but most of our residential is going to have electrical turning that corner in the lower 4', so nothing to gain with that method

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

that's a very good point unless you could convince ($$$) the electrician to run from the topplate.

In the south where more were on slabs on grade, the wioring came down from top plate, but here with panel often in cellar, it comes up and then across more often

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

Should be a workaround in there somewhere. Like, drill the loose stud at the 4' mark, and talk to Sparky.AitchKay

Man, I gotta try this Sketchup stuff. Yeah, that's how they do it -- plate maybe held back 3/4" instead of a tight 1/2".Come to think of it, there's no law you can't put a 1x6 or 2x6 with that system -- 1x6 would be plenty, since the board is so well supported. Or just blocks for the base and crown.AitchKay

>no law you can't put a 1x6 or 2x6 with that system -- 1x6 would be plenty, since the board is so well supported. Or just blocks for the base and crown<

Taht;'s what Popawheelie was saying. Just add it to all the other deadwooding/blocking prior to DW.

Commercial rockers hold the intersecting wall plate back a bit, and just set the end stud into the bay --the channels will hold it in place.

Wouldn't that require leaving all the plates back? Top two plates are below the ceiling joists and rock is tight to them........pluss it hangs below the bottom plate a bit.

How would I create an intersection/overlap of wall plates in your scenario? I would be creating a substantially weaker structure in a wood framed residential setting.

Good question....I was wondering the same thing.

http://www.cliffordrenovations.com

http://www.ramdass.org

look for an email from me.

<<<<

118313.22 in reply to 118313.13

If you were doing new construction, you would frame the intersecting interior partitions AFTER the exterior walls are framed and standing? How would you intersect the top plates where the interior partitions intersect with the exterior wall?

Always having used the intersecting interior partitions (when available) as braces to hold the exterior walls straight, I'm thinking I would need to do some extra bracing as opposed to running a diagonal down one of those intersecting interior partitions.>>>>

no....we don't need the interior partitions to tie... the best thing is exterior walls.... mooney furr ceiling

insulmesh walls

then erect partitions

the walls are plumbed and straightened with braces and adjusters... the partitions just get in the wayMike Hussein Smith Rhode Island : Design / Build / Repair / Restore

Does that order not cause Plumb/ele subs a hard time? Come back and feed the partitions?Spheramid Enterprises Architectural Woodworks

Repairs, Remodeling, Restorations

They kill Prophets, for Profits.

did i say insulmesh the walls ?

oops

Mike Hussein Smith Rhode Island : Design / Build / Repair / Restore

Mike...so you're saying just the ceiling joists hold the exterior walls from moving out?

http://www.cliffordrenovations.com

http://www.ramdass.org

So, getting back to my question.....do you intersect/lap or just butt the top wall plates?

interior , non-bearing partitions are 3/4 " below the top plate

to build , we erecy only the exterior walls and any interior bearing walls

the partitions get erected after the ceiling joists / trusses are installed

bearing walls get tied, partitions don'tMike Hussein Smith Rhode Island : Design / Build / Repair / Restore

To answer the original question: I install three blocks at 24" oc.

I butt the top plates.

I can also make a pretty good case that butting the top plates makes for a significantly stronger shell assembly assuming that there will be drywall backing applied on top of the interior partitions.

>I install three blocks at 24" oc<

like what Snort's got? 118313.9

Yes, except I wouldn't put those in the bottom (or top) like he does.

Then for the commercial-style, through-wall version, how about this:Use ONLY the top and bottom trim-nailer blocks, plate through on top only, GWB gets notched for plates at the top, also for elec. at 4' ht.Excellent insulation that way, LOTS less wood.Biggest problems I see are plating a job like that, and nailing the wall in at the right place at bottom. Commercial rockers are dealing only with a piece of channel, so it's easy to hold it back. They don't have a fully-framed wall to deal with.AitchKay

GWB gets notched for plates at the top,

Ya just had to turn this political didnja?

http://www.cliffordrenovations.com

http://www.ramdass.org

Yeah, been wantin' to notch that SOB for a while, now!AitchKay

<Yes, except I wouldn't put those in the bottom (or top) like he does.>Frickin' framers<G>http://www.tvwsolar.com

I went down to the lobby

To make a small call out.

A pretty dancing girl was there,

And she began to shout,

"Go on back to see the gypsy.

He can move you from the rear,

Drive you from your fear,

Bring you through the mirror.

He did it in Las Vegas,

And he can do it here."

Good point. As I said, I've never done it, but I like good, overlapping plates, too. Maybe plate the top through, and notch the GWB around it? That'd still be faster and tighter than conventional framing/rocking. Commercial rockers are usually just putting non-structural partitions in large, open spaces, and don't have to think about keeping a house standing!AitchKay

In your original drawing....leaving the insulation out would not really be the issue...in that configuration, insulation or not would hardly be measurable. There are other suggestions that would cover your insulation concern.

That whole 3-2x U intersection is very inefficient and what I was taught 80's and framed with for close to 10 years. It's poor to begin with but omitting the insul in the U just makes it even worse.

You are correct, but I would challenge you or anyone else even in a laboratory to measure the difference. My point was that to worry about whether insulation is or is not in the U is really a waste of good worrying time, that could be better spent on figuring a way to not use the U format of the framing.Nobody gets in to see the wizard...not nobody...not no how!

"I would challenge you or anyone else even in a laboratory to measure the difference. My point was that to worry about whether insulation is or is not in the U is really a waste of good worrying time,"In places where it gets cold, that un-insulated U intersect causes lots of mildew and condensation from the cold there

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

Wow 45 posts about something that is relatively simple. Back when I did alot of framing, used to use the U method but changed to the L ( 2/2x6 in most cases ) . The reasons: Insulation in the U would get soaked and settle down in the pocket behind the sheathing possibly causing problems later; the insulation in the U is of little thermal value. Insulating here is done much better by a specific company later . As far as the " commercial method " try to convince your client your crew that it might be a better way ! In some years of framing only used steel studs once in interioir wall framing ( they require different type of wire, plumbing in walls can be a problem if copper ) . Steel studs are for non-combustible construction I believe, ie. a fire rating.

>45 posts about something that is relatively simple.<

Is it that simple?

I don't like the commercial way that much either but it was good to learn. Framing here in the SE is predominantly 2x4 studs so some of the methods that work smoothly in the north like Piffins post where they place the 2x6 on the flat at the intersection location in a 2x6 wall (with 2x6 stud pile handy) aren't that easily integrated into the routine here. It's simialr to what I do but with 2x4 walls it's an extra step. The horizontal 2x blocking like Snorts & Jim Blue's might be the easiest and 'greenest' since you can use cut-offs and culled lumber and might be the easiest labor-wise to use in the process.

Maybe it is simple but it beats the Tavern.

cheers

Piffin's 2x6 stud backer is probably less labor intensive, but like you, we don't have extra 2x6s laying around. Unlike Jim, I do like some something of substance at the top and bottom for base and crown... that vertical 2x6 is not quite enough for my taste... but it will work.Fire blocking at interior soffits is another great thermal escape hatch. We use spray foam insulation, and the inspectors have said they don't see fire getting in the bays, but...This is what we do now, but I'm open for something better.And, how do you imbed those sketchups?http://www.tvwsolar.com

I went down to the lobby

To make a small call out.

A pretty dancing girl was there,

And she began to shout,

"Go on back to see the gypsy.

He can move you from the rear,

Drive you from your fear,

Bring you through the mirror.

He did it in Las Vegas,

And he can do it here."

For soffits I've done the similar with OSB but with a ladder type soffit framing.

To imbed the pic I attach the jpg to the message after I finish typing. Don't hit post, select the button to preview post. your attached files will be there. Open the files in another tab/window. Use the Revise button to return to the page where you enter your text and then copy the images from the new pages and then paste them in the text where you want them.

prior to any uploading I size the pictures to 400pixels high and then crop out whatever isn't needed in the width-wise direction. Reducing colors helps reduce the file size as well and really helps for the dialuppers on the DL. Even though the pics may be sized small they still may contain large amounts of data and can drag down the DL or they just don't check it out. It's better to start off with fewer colors than it is to try to reduce them later ina photo edit.

Using the Scene setting in SU of Shaded with Textures minimizes the color count of your exported 2ds which also reduces file size. In SU's standard view of the gray onteh bottom really adds file size that doens't add much to the image quality.

you must have pro... I don't think I can export anything other than a .skp... might be able to do it through photoshop, though.http://www.tvwsolar.com

I went down to the lobby

To make a small call out.

A pretty dancing girl was there,

And she began to shout,

"Go on back to see the gypsy.

He can move you from the rear,

Drive you from your fear,

Bring you through the mirror.

He did it in Las Vegas,

And he can do it here."

Try [File] [Export] [2d Graphic] and the chose your location and then file type.

I do have Pro but I know I was exporting 2ds long before I went pro.

"less labor intensive, but like you, we don't have extra 2x6s laying around. "I don't have ANY of the lumber needed to build just laying around. I figure up what I need and order it. How hard can it be to count intersects and order that many 2x6s?

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

Must be a habit to use scraps and culls for blocks... I was wrong when I said we didn't have stuff lying around... seems half of what we order is culled, ha.http://www.tvwsolar.com

I went down to the lobby

To make a small call out.

A pretty dancing girl was there,

And she began to shout,

"Go on back to see the gypsy.

He can move you from the rear,

Drive you from your fear,

Bring you through the mirror.

He did it in Las Vegas,

And he can do it here."

The horizontal 2x blocking like Snorts & Jim Blue's might be the easiest and 'greenest' since you can use cut-offs and culled lumber and might be the easiest labor-wise to use in the process.

Typically cut offs from laying plates and building headers.

The three block system is actually slower to do than an "L" buck. But, since it is the "greenest", I do it anyway. I like chewing up the chunks of plate stock left over from the various tasks. When I'm framing the interior partitions, I keep and use every chunk till they are under 10". I've even been known to create fire blocks out of two 8" pieces by lap nailing them.

One of the nice things about this style is that the inevitable minor adjustment to partition locations don't hurt so much when they come up.

You're wasting an inch. :)

Down to 9" and you can stagger the blocks. I use Vice Grip C-Clamps to hold the 2 pieces together while I shoot 2, maybe 3 3" nails. Never have to measure a stud cavity for blocking this way.

View Image

That's the idea John, but I'm not so sure about the need for a clamp. I like the idea for the same reason you did: no measuring.

I use the clamp to hold them together 'til the nails are set. If I shoot them without clamping I end up with a gap between them and that won't pass as fire blocking. I suppose I could back one up with a heavy hammer and shoot from the opposite side but I think there's still a risk of having a gap and then adding more labor to eliminate the gap.

These are the Vice Grip C-clamps I find pretty handy http://www.sears.com/shc/s/p_10153_12605_00920611000P?mv=rr and are the fastest thing I can think of for the the job.

YOu need a new gun..or there is something wrong with your technique.

I think I laid the first block on the plate in between the studs. I then laid the next one on top and then, using the floor and plate as the "sledge hammer", I shot the nail(s). No gaps that I remembered but if there was, I'd simply hammer them tight with my hammer.

mebbe I need the technique, been shooting them in place... flooor might be better

Thing is... place them like that, ya gets no insulation behind 'em...http://www.tvwsolar.com

I went down to the lobby

To make a small call out.

A pretty dancing girl was there,

And she began to shout,

"Go on back to see the gypsy.

He can move you from the rear,

Drive you from your fear,

Bring you through the mirror.

He did it in Las Vegas,

And he can do it here."

but if they're going in as fire blocking...

Gotcha... solid wood for fire blocks has caused us more trouble than their worth... seems it's really hard to keep them in the wall plane, and then there's those little teeny tiny ones<G>http://www.tvwsolar.com

I went down to the lobby

To make a small call out.

A pretty dancing girl was there,

And she began to shout,

"Go on back to see the gypsy.

He can move you from the rear,

Drive you from your fear,

Bring you through the mirror.

He did it in Las Vegas,

And he can do it here."

>seems it's really hard to keep them in the wall plane, and then there's those little teeny tiny ones<G><

seems to me we ought to be able to find a spray foam to do those little ones....

Actually, Hilti, for one, makes fireblock foam.http://www.tvwsolar.com

I went down to the lobby

To make a small call out.

A pretty dancing girl was there,

And she began to shout,

"Go on back to see the gypsy.

He can move you from the rear,

Drive you from your fear,

Bring you through the mirror.

He did it in Las Vegas,

And he can do it here."

v cool. Thanks for the lead.

http://www.hilti.com/holcom/modules/prcat/prca_navigation.jsp?OID=-22749

now to see what it costs...

You can get firefoam at the home depots and lowes

You guys are so wasteful -- (2) 7 1/4" blocks and a biscuit.AitchKay

silly carpenter, biscuits are for trim

:)

I'll have a dog biscut. Thank you.

Good Boy!

I use steel studs in residential, but only in basements. I think you misread the posts. Go back and take another look.AitchKay