116310.1

Several weeks ago I posted a question about replacing several rafters in my daughter’s house in MS. You asked if I had a drawing. Well, now, I do, along w/ some photos I took from inside the attic to show the sorry shape of the structure.

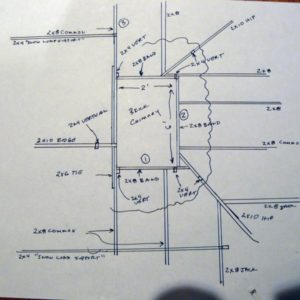

The Dwg is the first attachment & is a plan view of roof, not really to scale. The photos start in the lower left hand corner & proceed counter clockwise. They show the extent of the rot, which is pretty bad along the right side of the chimney. I anticipate replacing EVERYTHING between the jagged line & the chimney. Actually, the sheathing will be replaced out at least two feet from the chimney, if not for rot, for access to the structure from the outside. It is about 6 ft from the joists to the roof sheathing, so I can stand up, but my monster 19 yr old grandson, who will be my slave labor for the job, cannot.

Pls comment on my approach to fixing this abortion.

1) Repair/rebuild side 2 first, since it is worst & being held up by rest of sheathing. Cut an access hole between two rafters so I can get materials inside. Run a 2X4 perpendicular to rafters & support w/ verticals from load bearing framing along side base of chimney. Rip out rest of sheathing, cut off rotted ends of rafters & Hip at lower right corner, put in new band & splice/sister new rafter ends. I plan to replace anything that is infected w/ the black mold for remediation purposes. Replace sheathing

2) Do same to side 1.

3) Do side 3. Which will include the long common rafter right at the number 3. This rafter is apparently infected w/ black mold for its entire length. I’ll have to wait till I expose it to determine how badly it is involved.

4) The Ridge. It has a rotted end for the last foot or so, right next to the chimney. That should be easy to splice, since it takes zero bending load.

How to sister the two Hips, which define the roof lines? Since the space is cramped where I have to do that work, should I get a pair of steel plates to sandwich a spliced replacement end & hold them on w/ through bolts? I’d like to keep my splice joints as close to the end as practical to get away from sections of the rafters that take bending stresses.

Can I use the special screws used for building up beams & attaching ledgers to walls to sister new ends to rafters? Like to stay away from a lot of nailing in closed spaces. Yes, I have a Paslode framing nailer. I also have a 19 yr old grand son who works very effectively on the business end of a ratchet! (Not to mention the business end of a shingle removing shovel.)

When I finally get to flashing – can I use factory painted Aluminum flashing? Will it survive contact w/ the mortar? The existing galvanized is what rusted out & failed causing this mess. Copper is out, based on the cost. People laugh when I mention lead. What about stainless? Practical?

Can you still get true galvanized roofing nails? Or are they all just electroplated?

Don Reinhard

The Glass Masterworks

“If it scratches, I etch it!”

The Glass Masterworks

“If it scratches, I etch it!”

Replies

Looks like a nice drawing. But Don, you really need to repost the pics with sizes down around 250k or less.

"Put your creed in your deed." Emerson

"When asked if you can do something, tell'em "Why certainly I can", then get busy and find a way to do it." T. Roosevelt

I don't see much rot in the pics. They appear to be mostly discolored. You need to be sure the rafters are really compromised before doing that much work.

People use aluminum flashing all the time, it's ok for a long while but I'm not sure the cost of copper flashing would be a deal breaker.

Dam: The rot is pretty bad on most of them. Can't really say till I get it exposed. The long one may be just stain - won't know till it sees daylight. The ends are what are are compromised. W/ the atmosphere out there about (GASP!) Black Mold, I figure I may as well remove all the stuff that goes beyond staining while I'm in there. Daughter may want to sell house some day & buyers can be real dorks when it comes to hot button items like black mold & radon. We know - we lost a sale over radon that didn't exist; just because the house sat on a granite outcropping from Stone Mtn, GA.DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

I resized your images so it is easy for the old fuddy duddy dialuppers to lo look at.

Dam: 'preciate that. MOF, I don't know how to do that. I expected someone to complain (fairly) about their size, & further someone would re sample them. I don't even have a graphics package that will make a dwg. I only have Corel Draw, which is a pain in the patootie to use for that kind of graphics. You shoulda seen the photos before I attached them. They were each over 3.5 MB. I hit the "Quick Fix" button & that at least reduced them to where they were.Thanks.DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

Irfanview works great, and it's free, just clicked resize/resample, 640x480, and you're done. http://www.irfanview.com/

Cut the hip over the verical 2x4, that I assume is for additional support.

You can use prepainted alum. for flashing although around here we tend to use unpainted. When I have to nail them, I cover the nail heads with silicone, to stop the galvanic reaction.

Can't remember the other questions.

Thanks for the resizing of plans. I use DSL and it is still a slow load.

Frammer: How should I "Splice " the hip? If I just sister it, I now have the rafter defining the roof line jogging out of line. A pair of steel plates, one on each side w/ through bolts? A whopping 2X scab along side the joint?How well does aluminum last? I've read that the alkaline components of mortar eat away at the Al. That's why I asked about pre-painted.DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

A pair of steel plates, one on each side w/ through bolts?

Why not?How well does aluminum last? I've read that the alkaline components of mortar eat away at the Al. That's why I asked about pre-painted.

They will last the lenth of the roof shingles. if you have a long life product like tils or steel it is a different answer.

Don, as a former engineer---- i think maybe you are over anaylizing this.- understandable-- but still......:>) Looking at the pictures-------- i think maybe you are planning on replacing a lot of stuff that maybe doesn't need to go. some of it, yes probably------ but from here-- most of that looks like discoloration.

Of course-- i can't probe it with a knife or an awl------ but I have seen much worse that is almost completely black----and completely . at this point-- since you have pictures now--- and ACTUAL CARPENTERS watching--- I would happily defer to their specialty I AM curious about those vertical 2x4's------- I would never, have never-- seen that here----- I am wondering if it wasn't just temporary bracing used to assemble the thing---and really does nothing now? also--- in one of the pictures in the background----looks like something like a purlin???----- horizontal 2x running under the rafters mid span----- we wouldn't ever encounter that here. for me---- the less I cut off and replace at once-- the safer I feel it is for me----- but as dino suggested---- it might be faster cutting it all at once---- I just wouldn't do it myself-- and especially not as a DIY

regaurding the chimney flashing

I hear people say you can't mix aluminum with mortar---- it's done HERE that way all the time with no ill effects

possibly bare/mill finish aluminum in contact with wet mortar might be a problem SOMEWHERE but here we use factory coated aluminum as flashing almost all the time---- me personally? maybe 19 chimneys out of 20 are painted aluminum set in reglets ground in 1926 mortar. I will every so often encounter mill finish aluminum set in fresh mortar from back in the '60's----- with no problems.

Lead?-- maybe the occasional soil stack flashing from an old house originally roofed in slate---- but even those are mostly copper. In my area I absolutely would not use lead----- but if it is common in YOUR area-- go right ahead. ( I almost wish lead WAS considered acceptable here---- in a previous career as an industrial hard chrome plater back in the '80's I built anodes every day out of lead------ nowadays i would need to polish up my lead burning skills---- but back then we did tons and tons of vertical lead burning in sheet lead etc. I am sure I could do some totally rocking lead work even now, LOL Best wishes,

stephen

Stephen:

<Don, as a former engineer---- i think maybe you are over analyzing this.>

Better to over analyze it than have the roof collapse! OTOH - I very vividly recall a situation when I had a bunch of engineers working on a detonator manufacturing machine. Finally told them - it's time to shoot the engineers & get the project finished. We did, it worked! Kudus for all! Time to shoot this engineer!!!!<i think maybe you are planning on replacing a lot of stuff that maybe doesn't need to go.> Better to plan on doing worst case scenario than to be surprised when I have to do more than planned. This mess is so bad when you are right there & can touch it that I considered it dangerous to mess around w/ a lot of probing. Considering the long time I had to wait before working on it, could not afford to make it worse. That one rafter where the rim is rotted away is already being held up by the sheathing. I am suspecting that if you, as a real roofer, got into this mess & had to do the wholesale replacement I am planning on, would charge about $10,000 - and it would be well worth it and earned. As to the black - I am concerned about the future value of the house. We once lost a sale on our house in Atlanta because some nutcase woman feared Radon from a granite outcropping in our basement. We'd had a Radon test done & the level was far less than allowed. I've also seen irrational fear of asbestos remediation in a house. Also had trouble w/ nutcases in Bettendorf, IA over a house that was w/i half a mile of a remediation site. The house was about 500 ft higher than the site, which was right on the MS River. People who don't understand can be a true pain in the hemmorhoids! While I have the mess chopped open I figure I may as well replace anything that is infected w/ mold (as opposed to just stained). The rafters are fir, & I've sen a lot of staining on fir, just from getting wet. A heck of a lot cheaper than going back & fixin' it from scratch when Daughter tries to sell somewhere down the road.<at this point-- since you have pictures now--- and ACTUAL CARPENTERS watching--- I would happily defer to their specialty> That's why I'm here! Getting advice from those who know better than an engineer who is always warm, dry & working in shirtsleeves! Engineers design - carpenters build. I'm crossing over here! And I know it.<I AM curious about those vertical 2x4's------- I would never, have never-- seen that here----- I am wondering if it wasn't just temporary bracing used to assemble the thing---and really does nothing now?> Stephen, it gets better than that!!! A lot of that wood is NEW! It's also a different species than the original construction. It's what they are calling "White Wood" now, the original is DF. It obviously was installed well after the house was built in the 1970's. Especially the one you saw off in the distance. The run on those rafters is extremely long in my book for 2X8's & I'm wondering if they had roof sagging problems & put that in to solve the problem. In the area I'm going to replace, there is a bunch of that kind of stuff. Like they fixed the symptom, stalling off facing the cause - which I'm having to do now.<the less I cut off and replace at once-- the safer I feel it is for me> Amen to that Bro! I have no feel for what might happen, so I'm going to take it piece by piece. But - I have to take that side 2 out all at once, since there is no rim to support anything while I work on it. I'll do as John suggested w/ support bracing while I clean out the rot on that whole side.As to the flashing - I'm overwhelmed w/ the various, conflicting advice I'm getting. Each one solidly backed up w/ experience / reasons. Lead is out for the reasons you state. Irrational as those reasons may be. We both know lead is the best & absolutely safe if you don't go up on the roof & eat it! Heck - the aquifer running under Eastern IA has a lot of Radium in it - people aren't dying from drinking the stuff. I'm surprised the EPA even lets anyone live there. All the work in this area of MS is galvanized. I doubt if you could even buy Cu or PB out there, though I haven't tried. Here in Atlanta, I think it's Al. That's why I asked in one post about factory finished AL. New mortar is probably more alkaline than 30 yr old stuff. Unless the mortar is worse than I think from a cursory look at it, I'm going to do as you do - grind out a kerf & use Geocel caulk. If you don't scratch up the coating on Al while installing it, it should last quite a while - at least till the next roof is installed! I found 36" wide self adhesive membrane here in Atlanta. I'm getting a roll to take w/ me. I saw a lot of evidence of wind-blown water under the shingles close to the chimney. That's a real problem there - LOTS of near hurricane force winds accompanied by rain. Not to mention probably 25 bad thunderstorms per yr. And, there was no protection other than the step flashing going 4 inches out from the chimney. Lead - I came out of the explosives manufacturing arm of Uncle Sam's Army. A lot of experience w/ sheet lead floors, etc. As a manager, not an installer. There's a lot to be said for lead. Unfortunately, irrational, chicken Little ideas prevail. I know whereof you speak.Thanks. I'm ready, coach. Put me in!DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

Don,

I'm not sure just why you're so reluctant to employ lead in this flashing set up ??

Availability or some regulations that won't let you use it?

I second the lead. As long as the kids aren't on the roof licking it, it is the best flashing he can use. Maybe its an availability issue?

Lead doesn't bother ME one bit. I know better than to eat it. I do stained glass & deal w/ a lot of lead & solder fumes. You just protect yourself adequately & you are OK. Wash your hands frequently after working w/ it. Don't eat where I work; wash before eating; shower & wash hair thoroughly after working w/ it. Once it's in place, I just don't crawl up on the roof & lick it! <G>. There is just such an irrational fear in the general public, fueled by the environmental whackos in our midst. It just isn't really available at a reasonable cost, if at all. The problems w/lead in paint has slopped over into the use of lead anywhere and for anything.If I could run right out to a lead flashing supplier & buy the stuff at a reasonable cost (whatever that is), I'd do lead.Know of one in the Atlanta, GA area?DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

No, but I bought a bunch of full rolls last year for $60 for a 50 lb. roll - retails for $140 now.

If you wanted a roll for $60 plus the freight on 50 lbs. from Me to Ga. I'd be glad to let you have an 8" or 10" roll.

Let me know and we can swap info if you want .

Walter

Don are you planing on stripping the old roof completely or just patch. If you strip the roof completely you may see other damage to repair as well and going to the extent of the rapair it may be worth the effort to strip the roof as well.

How are the rafter tails and facia looking? It could be the best time the repair this area as well.

Tony: Just patching. But... the patch area is rather large - probably several squares. Just to get at the bad area & make access I have to take off a lot more than the bad area. I've seen the entire roof from inside - no apparent damage to it. I know there are no leaks. At least other than this mess around the chimney. The rafter tails, fascia, et al are in good shape.DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

Walt, I think it is probably not a common material there. We have the same problem around here, and shoot I wish I had some upon occasssion. I think the EPA has scared folks about the hazard without reguard to the good points.

I can see the ill effects from old paint being carelessly removed , but small amounts of chimney flashings well out of reach seems like overkill to me.

Walter

Try telling that to the state morons in NY.

I might need to consider it. What is the linear footage of an 8 inch wide roll? I'll need about 36 linear feet.I assume you do slate roofs. Do you do flashing the same way they do it w/ galvanize?DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

Have you considered copper? Looks beautiful and might be easier to come by.

Don,

I think it's 30 lineal feet on an 8" roll.

I always do a two part flashing system - the first , the base flashings of galvanized or copper or lead coated copper. The counter flashings that would be inserted into the reglets in the brick courses would be lead or copper.

I'll send you a link later of the procedure that I employ.

Walter

Walter: Thanks. I was wondering about the flashing nailed to the roof - could not see why it had to be lead. the problem is w/ the mortar, not the shingles.Look fwd to getting your procedures.You must be one of the few slate roofers in the country!DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

Don,

I'll dig up a Shutterfly album this evening and post the link here in the thread for you and anyone who would like to compare methods.

No , there are lots of slaters around still. It's having a resurgence just as art glass is seeing more folks trying to learn an older craft. The quality of the other roofing materials is bringing some folks back to installing a lifetime roof.

Walter

Don,

Hopefully you will find this album somewhat helpful.

Walter

http://share.shutterfly.com/action/welcome?sid=8cbsmrhq174

Don,

The link got posted in a post I addressed to me instead of you

Walter - Found them. Looks like you get called in when things become NASTY! Nice looking work. I'm familiar w/ slate roofs. There are a lot of them at West Point, NY. I've watched as some of them were re-done after maybe 50 - 60 yrs. They are truly works of art.Back in 1981, I met a slater in NJ. He had a contract to do some of the West Point roofs. Interesting conversation. He told me that there were few slaters around - that's why je was commuting the nearly 85 miles to that job. It lasted several months, since there were multiple houses to be re-done.DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

Don,

A local mason rebuilt the chimney and put in the lead and left it as the first pictures show.

Using Grace as a barrier to wind driven rain against the sides of the brickwork prior to the base flashings is always a good idea.

The lead or copper as counterflashings then just direct the water from the bricks safely down onto the roof flashings.

Good luck.

How about some pictures in another thread on your work with glass ??!! I for one would really enjoy seeing some of your craftsmanship.

Walter

Walter: Already found the 36" wide Grace stuff. Hazlett convinced me in his FHB article to use it. Here in Atlanta, it's tough to find the 36" stuff - mostly the narrower stuff for around windows/door, etc. Let me make sure I understand your sequence.Grace Membrane folded up the chimney & out onto the roof deck; galvanized step flashing; lead counter flashing. I notice you solder the galvanized. Do you use a torch or a whopping ol' iron?DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

Don,

The photos showed lead coated copper - though it looks a lot like galvanized.

Yes the corners are all soldered with 50/50 bar solder with a fairly large hand held iron. There is not much area to heat up so really almost any sized iron will work. You'll need a heat source to get it hot enough to work properly.

The brick joints will have to be ground out and then the counterflashings installed.

I'll repeat what I said earlier in this thread about sealing the masonry - even though you have no freeze/thaw cycle. I think you'll be well served by including that in your repairs - since there will be no easier time to do that coating.

Walter

Don remember if you do use copper use copper nails, any other will create electroliss eating away the copper.

Thanks for the reminder.I'd forgotten that little bit of necessity.DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

Thou spaketh a bookfull on that indictment of the EPA. Unfortunately, the EPA runs with the Environmentalist Whackos as a pack of ravenous wolves. Remember the Alar-apple scare & Meryl Streep a few yrs back. They have the run of the mill American scared of his/her shadow. No, you don't want lead based paint inside a house, but that doesn't mean that lead is bad all over.Lemmee tell you about the most dangerous chemical we use - it's WATER!!! You can drown in it & it doesn't take much. You can OD on it, inadvertently. I did while working in Saudi back in 91. Darned near died from it, & I now have permanent high blood pressure. Don't know if there is a true cause/effect in my case, but when I had my pre-employment physical in late June it was 120/70, like it had been all my life. After ODing on water, it's been high, but at least controllable.Lead solder in copper water pipes - HA - I think that's another crock of excreta foisted on us by the Nanny State. Lead pipes, yes - copper w/ solder - way out of proportion. Cheers!Don Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

That looks more wet than rotten. What is it like when you stick an icepick into it?

If the wood is not punky I'd spent my time on getting the flashing corrected and hit the wood with a borate biocide to kill any fungus or mold.

Bill: There is enough punky wood that the roof has to be removed to fix all around the chimney. What doesn't show is the rotted sheathing & rotted ends where the rafters bear on the band around the chimney. Also - you can see the one section of band that has rotted out & crumbled to dust, leaving the rafter hanging by the sheathing. It has obviously been leaking for years. At least it has not gotten below the roof structure into the walls & ceiling.While I'm at it, may as well fix the marginal stuff, too. From what I saw while up there, it's not good at all. Doing the flashing is a major job by itself. Can't see doing that & leaving trash underneath.My labor charges at ten cents an hour - it's worth it at that cost!DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

Pls comment on my approach to fixing this abortion.

I would build a temporary support structure for the undamaged part of the roof, then take a 10" circ and a recip and cut out the entire section you marked off in your drawing--sheathing, rafters, everything. Cut it into pie-wedges and have a big shovel or a crane standing by to pull each piece off and drop it in a dumpster. Only take an hour or so; the crane charges shouldn't be more than the minimum.

That will give you a heck of a lot more room to work, and you should be able to sister new framing to the old more quickly and easily. With another carp and a couple of good helpers, you could have it covered/blacked in in one long day. For the sistering, use structurally-rated adhesive and through-bolts with thrust washers. If you splice instead of sistering the whole length of the rafter, each splice should be at least 4 feet long and have fasteners in a W pattern 6 inches O.L.C. The cheeks of the splice can be steel, but framing lumber of equal grade to the original rafters is fine, too (just a bit bulkier, altho probably lighter).

Aluminum flashings in a mortar joint? Absolutely not. Some people may laugh when you ask for lead, but that's their problem. Lead will outlast anything else I know about. If you simply cannot find a supplier for lead flashing, go with the heaviest gauge galvanised you can find.

Yes, they still make 'real' galvanised nails; they are identified by the letters 'HDG' ('Hot Dip Galvanised') on the box. Don't even think about using 'electro-galvanised' ('EG') nails for this job. EG nails are not galvanised at all; they are electro-plated, a completely different process that deposits a thin film of soft, easily-scratched pure zinc on the nail. True galvanising requires temperatures of 860ºF to create iron-zinc alloys which are harder than the underlying steel itself. Too, the coating on a hot-dipped nail is more than an order of magnitude thicker than that on an EG nail (5 microns for EG versus up to 130 microns for HD).

Dinosaur

How now, Mighty Sauron, that thou art not brought

low by this? For thine evil pales before that which

foolish men call Justice....

Edited 2/7/2009 1:55 pm ET by Dinosaur

Dino: Thanks: You said what I had hoped for - except for one part. The crane is not part of the equation. 1) would rip up the yard in rather mushy early spring southern MS & 2) Cost more than my 19 yr old grandson, who is condemned to his Grandfather's Gulag for this job. He'll be lucky if he gets thin gruel to eat & a 2X10 to sleep on. He will be watched carefully by 10 dogs ranging from a Dobie down to a Shi Tzu.We are lucky - a walk down the length of the ridge takes us to the asphalt drive, where we can spot a container to collect the trash. A couple questions - 1) If i only have to lop off about 2 ft out of a length of nearly 20 ft, so I need a sister that long (4 ft)? Seems to me that there is almost zero bending moment that close to the support, it's nearly all shear.

2) Save me the research - what's a thrust washer as you define it?

3) What size through bolt? 1/4, 3/8, 1/2 inch?

4) How thick should a steel cheek be? 1/8 in? 1/4 seems like overkill, especially if I have a sheet on each side.

5) So far, when I ask for the true HDG roofing nails, they look at me like I had lobsters crawling out of my ears. I have used a bunch of HDG Simpson nails on some work on my house. I do not like the EP nails at all.

6) If you read all the posts in this thread, note that some folks advocate Al flashing. I'd really like Cu, but that is priced out of my range. The house currently has galvanized on it & therein lies one problem - it rusted through & failed - that's the cause of my grief today.Thanks for the comments - they are really helpful.DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

1. I make a distinction between sistering and splicing. When you sister a framing member, you double it with new material for its entire length (or as much of that length as is practical). When you splice on a new section to a cut-off member, you bolt cheeks to both sides, extending two feet above and below the cut by rule of thumb.

2. Thrust washers are simply big flat washers that prevent the head of a bolt from crushing down into the wood as you tighten it. (You don't need them if you're using steel cheeks, just a lock washer under the nut.)

3. 5/16 or 3/8.

4. I'd guess that an eighth should be sufficient, but when you start specifying structural steel parts, it's best to check with an engineer and I ain't one.

5. http://www.nationalnail.com/Catalog.asp?s=1&c=88&f=376&dd=ON That link will get you to a page at National Nail for HDG deck nails, but check the nav bar at the left and you'll see all sorts of HDG nails. (I'm on dial-up so I couldn't wait for them all to load.)

6. Aluminum is highly subject to corrosion by portland cement; and I would never use it for step flashing in a mortar joint. A good quality, properly installed, hot-galvanised flashing should last a minimum of thirty years. I wouldn't give aluminum 5 years before it starts to pinhole. As I said, lead would be even better than galvanised, but I am aware that finding lead sheeting today might involve a bit of running around.

You might ask CU if he can recommend a source of copper at a price you could afford; doesn't seem to me from your drawing you're gonna need a whole lot to flash that chimney.

Dinosaur

How now, Mighty Sauron, that thou art not broughtlow by this? For thine evil pales before that whichfoolish men call Justice....

Don,

In addition to properly reflashing the chimney - I would also seal it with one or preferably two coats of the best masonry sealer you can get.

Walter

Thanks. Hadn't thought of that. It's a 30 yr old chimney & probably hasn't been sealed in its entire life. OTOH, it never sees freezing weather in Southern MS, about 100 mi north of New Orleans. When we went up on the roof to find out why the joint was leaking, we found a date scratched into the cap - somewhere in the 1970's. But... the mortar was in amazingly good condition for its age.DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

Cake, brother. Just get a good sawzall, cut it back and remove to solid rafters. Rebuild in reverse order. Bring a shingle to supply house to get best match, it will take several years for shingles not to look like a fix. Heck, if your not all that confident with your rafter cutting skills, label everything you take out and number it. Use it for template for new wood. Scaffolding rents by the week at Sunbelt Rentals around here. Bring plenty of beer for help.

Edit: keep picture diary to post on Breaktime!

Edited 2/7/2009 5:53 pm ET by arcflash

Arc: I've been doing this job in my sleep for about a week, now. I really don't want this roof to collapse on me. I can just see me whipping around that sucker w/ my big, ol' ugly Bosch recip, cutting everything in sight & when I close on the start point having it all fall into the living room! This house is the model for that movie "The Money Pit." The roof is just a part of it. Last year, in Jan, I had to rebuild the air return to one furnace because there was a slow, long time water leak in a shower head that caused a ton of wonderful black mold in the return. In the process, had to tear out one wall of a bathroom. We have yet to get back to that because other king cobras keep crawling out of the woodwork threatening to bite us. This roof rebuild interrupted a second bath remodel. So, right now we have two out of three baths out of order & I'm working on a roof. At least it will be March when I do it - not JULY! Electrical would make William the Geezer die of apoplexy! We keep finding J boxes in the attic that have no lids on them. Even better, the wires are all twisted together without nuts on them, being insulated from one another by air. The inspector didn't find them because they were buried in FG insulation.After this weekend, I think I know everything I need to make the first cut in the roof. I've never done anything like this, but I have built my own house, so it's not strange territory to me. I think of this mess as an electrical engineer w/ a big dose of civil, not as a skilled carpenter, etc. I learned early in life that there's a big difference between an engineer & a technician. They really need one another to survive. That's why I've been picking the brains of the good folks here.The house is in Brookhaven, MS. There's a HD, but only one rental place. They are not fully equipped, but do have most things. I've already learned what's in the various towns around there that fill the voids.DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

From what I'm seeing from the drawing (brief glance), it appears this chimney juts out of a hip roof? No sweat man, your over thinking it. Even with a steep pitch you can start a cut just about anywhere in the rafter bay all the way up to the band board without worrying about collapse. Thats the beauty of it. Each rafter will support the load of what remains, which by the way, is only the weight of the roof deck and shingles. Plywood over the ceiling joists will protect the plaster underneath from falling debris.I'm willing to bet that you and a few freinds could have it demo'd and rebuilt in about four days. Pressure treat your band boards, flash the chimney/deck joint.

Don,

The quickest way is to make the big cuts like Dinasaur mentioned. Cut back 2' or so to clear your rot. Cut them down to chunks small enough for your prisoner, er... grandson to hump off the roof for you. That ought to give you enough room to work quickly as opposed to laying on your back under the roof deck the whole job. Brace as you see fit, but if yoiu cut them all at once, it will indeed need bracing to hold it pu. I'd run 2x up under the rafter and attach the brace to the rafter with a scab on the side so that the bracing won't interfere with the installation of the sisters. Brace before you cut if you weren't already thinking that.

The sister will be the member carrying the load, and the filler put in line with the remaining original rafter wil be doing very little load carrying. So with that in mind I'd follow the cantilever rule of 2:1. So if you cut out 2' the sister will have 4' extending along the original fater giving you a 6' sister. Nail it with a 5 pattern found on dice with about 4" - 6" interval between the 2 and the 1 on the dice. PL const. adhesive if you want to glue it too.

That rim band ought to be a size larger than the rafter and not the same size as it shows in your picture. 2x8 rafter needs a 2x10 band/ridge.

The hips are going to the biggest PITA. I'd cut back the jacks similar to how they're cut now to allow the sister to be set in and then re-attach. The hips will call for the most decking to be pulled I think.

Look to GRK or McFeely's for screws with hex heads (I think I saw them there) so you can drive them with a 1/4" or 3/8" drive ratchet, impact with 6 point socket or... Don't trust the screws you get at Lowes or Home Depot. I've tired a few different brands from them hoping to find something locally but nothing has been worth the money or effort so far.

If the chimney is not in use (ie it's not venting a gas water heater, gas furnace, or similar appliance) you ought to be able to spread a tarp over the chimney and open holes to handle rain. I bet they get afternoon storms like we used to here in GA. Be very sure of yourself when it comes to covering the chimney.

The inlaws have been here so I found work to do in the office and here it is in the form of 3 pics from a model I threw together.

BTW good sketch.

John: Many, many thanks! As I've been doing this job in my head & in my sleep, my concept has converged to your solution. Every post has helped me considerably. Starting w/ Hazlett way back in my first series, he convinced me that I didn't want to do it from the inside. I found his article in FHB & that helped a lot, also. You are right about lying on my back in that attic. It's a mess. I'd decided that the ceiling needed 5/8 ply on it for walking so neither of us wound up in the living room. That assumes, of course that both feet would be in the same bay. If we were straddling a joist, that would REALLY hurt. I'd also planned on bracing the rafters before cutting out the major stuff. I'll have to cut an access hole to get materials in for the bracing. It is impossible to get anything to this end of the attic through the access hole in the far end of the house. You made me see the error of my bracing concept - I was going to run a 2X4 along the bottom of all the rafters & support that w/ "verticals." Your idea of the scabs is better. Also, I will sister it as you described. It will be cramped getting that Paslode in there, but infinitely better than a framing hammer. But - for the sistering schedule, I'm going to use GRK type screws. I did that for a 14 ft pair of Glu Lams for a big bay window bump out on my house. MOF, the same Gulag inmate drove the screws, so he's already been trained. What really surprised me about the current structure is the screwy sizes of the band. It really should be a 2X12, but it's 2X8, all the way around. I had been toying w/ the idea of using PT for the band - you convinced me that's the way to go. What I cannot tell is whether or not the band is attached to the chimney. It doesn't appear to be - no sign of nails. Should it be attached? I won't know till we rip that trash out.The chimney is already tarped. Daughter & I did it back in Jan, the day after we discovered the leaks. It's just a fireplace, so it's not a problem for anything else.I've been scurrying around locating as many parts as I can here in Atlanta. I have a small trailer so I can just throw it into the trailer & haul it out there on 7 Mar when we go. Job has to be complete by Thurs, 13 Mar, so we will be hustling. Found the screws, self adhesive membrane for under the flashing. I think I can get true Hot Dipped Galvanized roofing nails here, also. I'm sorely tempted to use Simpson rafter hangers for assembling the mess. Have to see if they are available here in stock. Trying to locate some heavy galvanized flashing material - heavier than what I find at Home Depot.Your dwgs capped it off for me. A good touch. Thanks for preparing them. You have a much better graphics package than I.DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

Have you tried to find any lead in the ATL area or are you content with the galv? I haven't had a need for lead (don't go up on roofs) but think it would be good to know a source.

I've always been under the understanding that no structure should be in contact with the chimney, that there must be clearance (can't remember the dim. off hand though) between the wood and chimney or fire safety issues and building code requirements. You might be able to put temp spacers between your new structure and the chimney to establish the gap but the chimney and adjacent strucures needs space between and free standing of each other as I see it. CAreful you don't bang on the chimney too much.

For your access hole I wouldn't worry about cutting just one of the commons while it was unsupported. I wouldn't cut the whole gang or 2 adjacent ones w/out the supports though.

I paid a lot for the software: $0.oo (free). Good thing they took credit cards and offered financing. Find it at Google Sketchup. Pretty amazing for free, eh?

It's good to have inmantes, my kids are still too young to assign to hard labor yet.

Inlaws are gone and lucky for me & them there's no bodies to dispose of.

John: See my post to Hazlett this AM for a quick & dirty update.

BTW - the dwgs you made have paid off for me. Thanks for the effort. I have the first two braces in to make sure the roof didn't cave in or distort badly. I cut a minimal hole for access to the attic & will now open it up to the final size I need to replace the rotted ends of the rafters. I should have the first side reconstructed today. daughter finally got me a helper last night. Should go faster than lasterday.

Have some photo, but are trapped in my camera till I get back to Etlanner in a couple weeks. BTW - all the trees are fully leafed down here in southern MS. The Crepe Myrtles are even in leaf! Azaleas are at their peak. We are just getting blossums on our flowering cherries up in Dawson Cty. I dec ided I don't want to roof a house in mid July in So. MS!

DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

>I decided I don't want to roof a house in mid July in So. MS!<

Same goes for Etlanner. :)

Hey! Thanks for the follow up on this. Most people ask the quesitons and never come back to tell us how it goes. It's nice and will be nice to see it as the repair progresses.

I don't work with masonry chimneys that much but I think you need a gap betweent eh masonry and anything combustible.

Things are just starting to bloom here, Brad. Pears, Red Buds and some of the Cherries are in full and dogwoods are starting as well as the Forsythias. My El toro Zoysia is starting to move already but it will be May before it starts into high gear.

Is that helper the indentured servant grandson?

Edited 3/21/2009 2:16 pm ET by john7g

John: What a mess some of it is - worse than my photos showed. There was rot that just didn't show up. I'm tearing it out back to sound wood. Have cut the rotted ends off 3 common rafters & one Hip. Naturally, when I went to cut the first jack so I could put a sister in along the hip, all the nails were in the saw path! Tomorrow I'll get that hip sistered & start around the corner.

Don't know about code & masonry chimneys - but the current structure actualy bears on the chimney in at least one spot. A hip runs right up to the bricks & appears to be nailed to it. It is the last hip I'll work on, so I'll try to think of how to keep from having that happen in my work. That long rafter appears to be worse than I thought - may have to replace the whole thing. Found a lot of hidden rot in top end. There is evidence that someone tried to repair leaks w/ some kind of black glop that didn't work. That long common is the last rafer that I work on. It is 24 ft long & the longest 2X8 I can buy is 20 ft. The existing is a Doug Fir board. All I can get now is SYP. This will be a challenge!

DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

glad it's working for you,

stephen

Stephen: Pls see a rather long summary I sent to John7g tonight.

Just want all of you guys to know how much I apreciate all your advice on this project. I could not have done it w/o you.

Thanks.

DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

John: Well, Day THREE on theroof & I haven't fallen off yet. Got the first hip sistered. Ditto two common's. The jack I cut was a perfect fit for the sister. Working on second side. Got the common cut off, braced. The rim fell apart when I hit it. Tomorrow the new rim will go in & Ill sister the common. It's going just like the dwgs youmade for me. They really helped a lot. All is fitting well.

Tonight I figured out why the problem started in the first place - absolutely crappy flashing! They didn't overlap the counter step flashing enough, allowing rain to blow in between the individual sheets & run down behind the underneath flashing. I can see where the water has been getting behind it & out about a foot on the sheathing under the shingles & 15# felt, that's why it took so long for the leaks to cause visible damage. I'm going to use Stephen Hazlett's advice & use a membrane up the chimney a ways & out under the flashing for about 2 feet. Why not, the stuff is 3 ft wide & I have no other use for it. I'm also going to raise my counter flashing a course of bricks so I can overlap it longer.

I've decided to take the roofing off to the first sheathing joint & replace the sheathing to that point. I'm only going about 18 inches on cutting off the rafters. that makes sure I'm into sound lumber. I've judged the soundness of the sheathing & lumber by how hard the nails are to pull. As soon as they fight me, I know I'm into good stuff. Some of them I can literally pull by hand, the wood is so rotted, or on its way to being rotted. It's obvious when the rafters are sound by examining the end grain after cutting it off.

I have the two long commons that lie adjacent to the chimney on the one long side. I am going to place the excess mebrane between the new rafters & the masonry, that should protect them in the future. It will also save me from buying PT lumber for a couple extremely long boards.

So far, it's going extremely well.

Thanks again for all your help.

DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

Glad it's going well for you, Don.

I do the Sketchup models for even some of the basic stuff. Glad they helped and it's working well for you, rehearsals are always good.

>decided to take the roofing off to the first sheathing joint & replace<

When removing things for access it's a fine line between saving material & man-hours and slowing yourself down by limiting your access costing more manhours. I've always tended to go bigger just to eliminate the irritation of the confined area.

John: Removing sheathing is a double edged sword. I first have cut back about 2 ft to see what is under it. That alows me room to work on the rafters, which, so far, I've been able to cut off at 18 inches & find sound lumber. I have one section between rafters that I've cut back 4 ft for access. Amazingly, the rafter spacing is 2 feet! Really makes for a springy roof in general. I have decided to remove sheathing back to 4 feet for strength & convenience of having a neat, straight line to work against while rreplacing sheathing. I don't want a 1 or 2 foot band of sheathing in the middle of the roof. The second edge of the sword is my lifelong fear of heights. Having a gaping 4 ft maw staring me in the face would be impossible to work around at this stage. I'll remove the rest of the sheathing just before I'm ready to replace it. Also, it gives me a line of shingles that is going to be ripped out to walk on & mess up the edges ofwhile mucking around up there. I'm probably mucking around about 10 times as much as you guys who know what you are doing. That 15 lb felt under the shingles is another problem. It absolutley crumbles when exposed, it has deteriorated so much from the heat over the years. I'm still trying to figure out how to remove several courses of shingle w/o destroying the crappy felt so I can have an overlap when I lay my 30 lb felt. The shingles aren't too bad, especially on the north slope. The south & west slopes are something else. Those shingles are literally fused together from Sun.

I also learned from one of my daughter's neighbors last week that there were three houses in a row that were re-roofed at the same time, by the same contractor. If so, they may have the same flashing problem around their chimneys as this one.

On to day 4 on the roof. Hoping I don't fall off yet again. All my friends & mere acquaintances have formed a chorus singing the refrain"Be careful on that roof!"

DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

If you can't get to old felt that you think is good enough to lay the new stuff down on top of, you can run the bottom edge of your new felt out on top of the last row of shingles left down. It's far from perfect and it may be difficult to hide it well but it will put the draining of any water out on top of the shingles instead of it running willy-nilly under the shingles.

The highest risk of water getting beneath the shingles is where you're working now, and probably very little risk in the field below your repair areas.

well..?

John: Deep subject!!!

Spent yesterday & today on the ground doing little things that had to be done eventually. Yesterday was the threat of rain all day, & I thought it was coming sooner than predicted. In reality, it didn't come till early this AM, the rained like mad all AM. Cleared up in PM.

Tomorrow looks like I'll be able to get back up there. Don't know if I told you - but I bought some Truss-Lok-Z screws to do my sister act they go in slicker'n an eel dipped in nose mucus w/ a Bosch 24 vold battery powered drill. If they don't, I can always use it as a hammer! The screws, plus glue, will hold. Today I found a 24 ft 2X10 just in case I have to replace the entire long common rafter that I know is rotted out at the top. I've now been able to see its companion on the other side of the ridge & it is rotted out on the side that was against the brick chimney. Fortunately I'll be able to save most of that rafter, lopping off only about 3 ft at the top. About 2 ft of the ridge has to go. As I recall, ridge rafters don't really carry load, & they can be spliced right in the center of a span between rafter pairs. Found an exact match on shingles up in Jackson after an hour on the web & the phone. Stumbled ontgo a neighbor who told me the house had GA Pacific Shingles, now made by Atlas. There is only ONE Atlas dealer in the area & I found them.

I'm going to take a photo of the screwy bricks in the chimney. They caused terrible problems w/ the flashing because of their "sculpted" outer surfaces. You cannot get the counter flashing anywhere near flush against the, leaving 1/2 inch gaps to allow water to get behind the step flashing. Will need some ideas about how to fix thqat w/o cutting out several courses of bricks & replacing them.

While searching for that 24 footer, was in a lumber yard & a contractor standing by said that here in MS you have to support long rafters every 12 ft. That can explain why there is a whole pile of new wood in the attic supporting the long rafters. Some framer on BT commented that he saw a whole bunch of what appeared to be unnecessary wood in the background of one of my photos.

This gets more interesting w/ each assing day.

DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

John: remember me saying that i didn't want to repir a roof in Southern MS in Mid-July?????

Well, today is 9 July, close enuff for Gummint work to mid month & I'm going back up to finish the roof! All sorts of things got in the way of finishing it while it was cool. So, here we are, back on the roof, struggling to get it done before the first hurricane of the season.

Ready to start replacing the sheathing. But... have to get in & rip out that long rafter that is causing me uncertainty & grief. Discovered that the HVAC unit in the area where I am working needs to have major work done on its plenums & ducting. probably have to make some major mods to that installation. Have an HVAC duct guy coming to look at it while we have access through roof. Access via attic crawl space is a pain where pills only reach while being eliminated. Should be interesting. found a long seam in joint between supply plenum & top of HVAC air handler was wide open & trying to A/C the attic space. At least we now know why the A/C unit ran all the time w/ little effect. Did a temp fix w/ aluminum duct tape. Now for the real thing while it is accessible.

DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

all the best laid plans....

be sure to drink plenty of water, tour pee should be clear & copious and that means your drinking enough. Be careful with to much gaotrade and the like.

Even thgouh it's overcast here on the beach, its still better than any great day on the job.

got any nuts yet?

John: Your advice on water is truly preaching to the choir!!!!! I OD'd on water while working in Saudi Arabia back in 1992. Put me in the hosp for a week, came out w/permanent high blood pressure. My mistake was keeping up w/ a guy who worked for me that was an old desert rat. I found out after swilling down two liters of water in an hour & being rushed to the hosp that he had LOW BP & his kidneys processed water like a fish. Mine will only handle half a liter per hour. Bummer.

Got a football lineman to lug the shingles up the ladder. At my advanced age, I can barely lift them, let alone lug them up a ladder.

Will keep you posted on progress. No nuts yet. To early for them for crying out loud - it's only July.

DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

I'm not goint to let me forget abou the nuts, got a calendar reminder set up for it. Next is to not let you to forget. Its truly a rare opportunity.

sorry about the hi BP.

John: First shingles went on lasterday PM. Hotter than the 7th furnace in Hades on roof. Cracked an egg & dumped it on shingles & it fried!

Got parts of three courses on. Boy, the color match between the original color & 7 yrs of hot Sun are dramatic! Had to figure out how to weave in new work & a hip & a valley - something I really didn't want to do. Also had to figure out how to remove shingles w/o destroying underlying 15 lb. felt that was crispier than toast straight out of the toaster. Took your advice & lapped new 30 lb. felt over top of last course of old work. Will have to get some kind of roofing goo to take care of the fact that felt covers the new black goo on theunderside of new shingles so there won't be a bond between new & old work w/o somehelp. A biggger challenge was figuring out how to get new felt under old shingles at joint w/ valley shingles where they crossed valley from other side. Gingerly lifted them up & slid about a foot of felt under the old shingles. Now all I have to do is go under various layers & nail them back down. Recall I asked about using the plastic capped nails for holding down the felt. Boss Hog said he used them on a job in LA & they really didn't show. I discovered lasterday that if I use a minimum number of standard roofing nails to hold the felt in place that you can put the plastic caps in as you shingle by placing them about an inch above the course you are installing & they sit flush w/ the top surface of the last row of shingles, so the next course doesn't show the bulge.

Bought a 24 ft spruce 2X6 to sister on the long rafter that was affected. Started taking off shingles & sheathing on a strip about 6" wide paralleling the rafter & atop it. Judged rafter's condition by how tenaciously it held the old nails holding the sheathing on. Only have to replace the top three courses of sheathing. Top one was so bad you could pull the nails by hand. By the time you got to the bottom of the second course, they fought back w/ normal strength. I have about 12 feet of bad rafter, so I'll be sistering as much of the length as a 24 footer will mate to. I'm going to take out full widths of sheathing so I don't compromise the strength of the roof.

As an interesting side bar. Read a post by someone who decided that humping full packages of shingles to the roof was a lot of work. At about 80 lbs per package, that's the understatement of the ages! I even have a Jr. college football player helping me & he agreed that a full pkg was too much for him. We opened one up & started w/ 4 shingles at a time. Gotta find a better way - that will take forever & a week to do 4 squares! I'm teaching this kid that there are good reasons to finish school, even though he is learning well how to do some basic carpentry & roofing. Doesn't complain.

Gonna finish up one side of the roof shingles today, starting at 4:30. That's when the temp drops to the point you can touch the roof & not get second degree burns <G>.

Really looking fwd to the flashing. That means the job is almost done.

DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

They don't make football players like they used to. I had a kid once who was football, plus state wrestling champ at 167# He was humping up two at a time until I told him I was worried about my ladder failing under him as he RAN up the ladder two stories. He ended up as a contender to go to the Olympics one year as a wrestler. Even at my age, I can still carry a full bundle up.

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

Piffin: Real problem is doing the carry 9 times in 95 degree heat w/ a humidity to match, then last the rest of the day. We started out at 4 shingles so I could be sure I would last the day. FB player does the ladder bit & I haul them up the roof. Up to 6 now - probably go up to 8 (about quarter of a bundle). Since I OD'd on water while working in the desert, I don't tolerate heat well at all. Can't have the boss dying in mid-day! The way I wrote, really sounded like it was him that had the problem. Not fair to a good kid. Been some really funny moments, like carrying the shingles from the garage to the ladder. We'd share the load & boy, did we walk slowly. Finally figured out that we were standing on the same side of the bundle & his feet were getting tangled w/ mine. The slow, awkward pace was killing me. We got on opposite sides & walked twice as fast. You gotta remember - we don't do this for a living!

My kids are really annoyed at me for continuing to try to do as much as I do. They joined my cardiologist, but he finally gave it up, deciding I'd work till I dropped, no matter what he said, leaving kids & wife to nag me. Medication really takes the wind out of your sails sometimes.

You should experience the load our troops carry in Iraq. No. 1 Son came through on his way over. Had all his personal gear w/ him, including body armor, etc. I have a 1960's VN era flak jacket I wear while using my table saw to protect against kickbacks - take one in the old PM & it would be curtains for me. Guess I'm attached to it, since I wore one for a year in VN. We traded gear to see what each other had to tolerate. How those guys survive w/ the load they are carrying is unbelieveable! The body armor weighed over 40 lbs. Then you add pack, weapon, ammo & water in 100 degree plus temps. Makes me feel like a real wimp! My old flak friend weighed a mere 12 lbs! Even our steel pot weighed less than the Kevlar version they wear.

BTW: Cardiologist & I discussed where I go in about two yrs if Uncle Sam won't allow me a new battery when the current one dies. Mexico is most likely place, followed by Thailand & India. New PM costs about $22,000 plus surgeon & hosp costs. I absolutely refuse to take a pain pill & wait to die! Too many projects to do.

DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

From all your previous writings, I had you at about 60 YO, not &@!Good for you and bad on 'bama

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

sounds like good progress Don. Slow & steady finishes the job.

I wouldn't be humping those shingles on as a as needed basis. I'd hump them all up early one morning, as early as possible and distribute them across the roof top at the job area. Be mindful of how hot the shingles that you're walking on as you can do some pretty good damage at the heat of the day.

72? Christ! Nearly as old as my Dad nad a lot more mobile than him. Fomr my observations from life of those enjoying the later years in life are the ones who never quit or surrendered. Slowed down, yes, that's ok, but no surrender.

7g

John: Got about a square finished today. You spaketh a bookful about what you can do to new shingles during the heat of the day. Discovered that the first 9 courses were all upgescrewed, so did the roofers' rip stitch & removed all but the first two courses this AM. Finally figured out how to get them properly aligned. First day's work wandered all over the place. Got the entire north face of the roof done, up to the point where I have to flash the chimney.

Tomorrrow looks like rain all day, so will be off in the bathroom trying to get it ready for tile. Got caught by a VERY sudden rain lasterday & a sudden sprinkle today. PITAto close it up - especialy w/ that chimney in the middle.

A true stroke of luck. Daughter having some trees taken out & the tree guys offered to hoist the shingles up there w/ their tractor. Think I'll take them up on that! I'm crazy, not stupid.

Don Don Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

John: Got the last, long rafter in today! Jubilation ! Went in easier than any other piece. Sistered a 20 ft setion on it. Couldn't get anything longer in there. Has a 12 ft chunk cut off the original rafter.

Started the sheathing on that side of roof. Gonna have to close it up for about 2 weeks, again. Be back in early Aug to complete job. This thing has taken on a life of its own!

Finished A/CMods lasterday. Took the contractor from 7 AM til about 2 PM. Cannot imagine how long it would have taken if I hadn't had the roof open so they had easy access to the unit. Can already see a difference - rooms in back section of house now uniform temps. Aren't A/Cing the entire attic through leaks.

Isn't there a way to install shingles from the top down? How do you make sure that when you meet the old shingles that they line up & all courses look uniform? That sure would make life simpler snce I have to tear off the old roofing from the top down.

DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

how's it going?

shingling from the top down sounds good until you try kneeling on the roof with your head below you adze for a while.

lining up the shingles has always been a task for the chalk line for me.

John: High BP is nothing. A couple pills a day takes care of that. I am more afraid of Obama Care than anything else. That will kill me if al the predictions from Tom Daschle are correct. The new system won't spend a dime on me. Consider: 72 yrs old; prostate cancer survivor, high BP, pace maker, arthritis, PTSD for nearly 40 yrs, survived an auto accident that was supposed to kill me. I'm not cost effective to spend health dollars on when there are all sorts of uninsured who need care. Other than the fact that I can still work 15 hrs a day under the right circumstances and have 4 kids & 6 grand kids who think my wife & I are pretty neat folks.

DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

LOL, the sooner they finish you off, the better the books balance at the SS office!

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

Stephen: Well, I opened up the roof lasterday. It was the best of things & the worst of things. The actual rot in the rafters only extends out about 6 inches. It is easier to replace about 18 inches (to ensure that I get all the dormant mold, while the roof is disassembled than to save pennies on materials & have to go back in several years & re-do the job. The rim around the chimney fell out when I uncovered the roof. Some of the sheathing is rotted to crumbs. The roof structure was built before the chimney put in. I can tell that because the nails through the rotted out rim are still there, stuck in the end grain of the rafters, thoroughly rusted. My plan is to screw the new PT 2X10 rim to the chimney to hold it in place while I reconstruct the new rafters. I'm going to attach the rafters to the new rim w/ Simpson HDG Z rated rafter hangers. After it is all assembled, I'll remove the screws into the chimney. Those 2X10's are HEAVY!

The shingles are in pretty good shape - BUT - the 15 # felt crumbles when I remove the old shingles. Finding a way to join the new 30# felt to the existing roof is going to be a chalenge. I don't want to replace the entire roof because the old felt crumbles!

Anyway - the advice you gave me for this job hqas paid off handsomely! I really appreciate it.

Thanks, once again. I'll post some photos when i get back home & can get them out of my camera.

I've realized one thing while starting this job and spending my first day on the roof - You don't try to do anything on a roof in a hurry - because the only thing you can do fast is to fall!

Don

The Glass Masterworks

"If it scratches, I etch it!"