How to Trim a Basement Window

When trimming windows in thick walls, you need wide extension jambs and a deep stool.

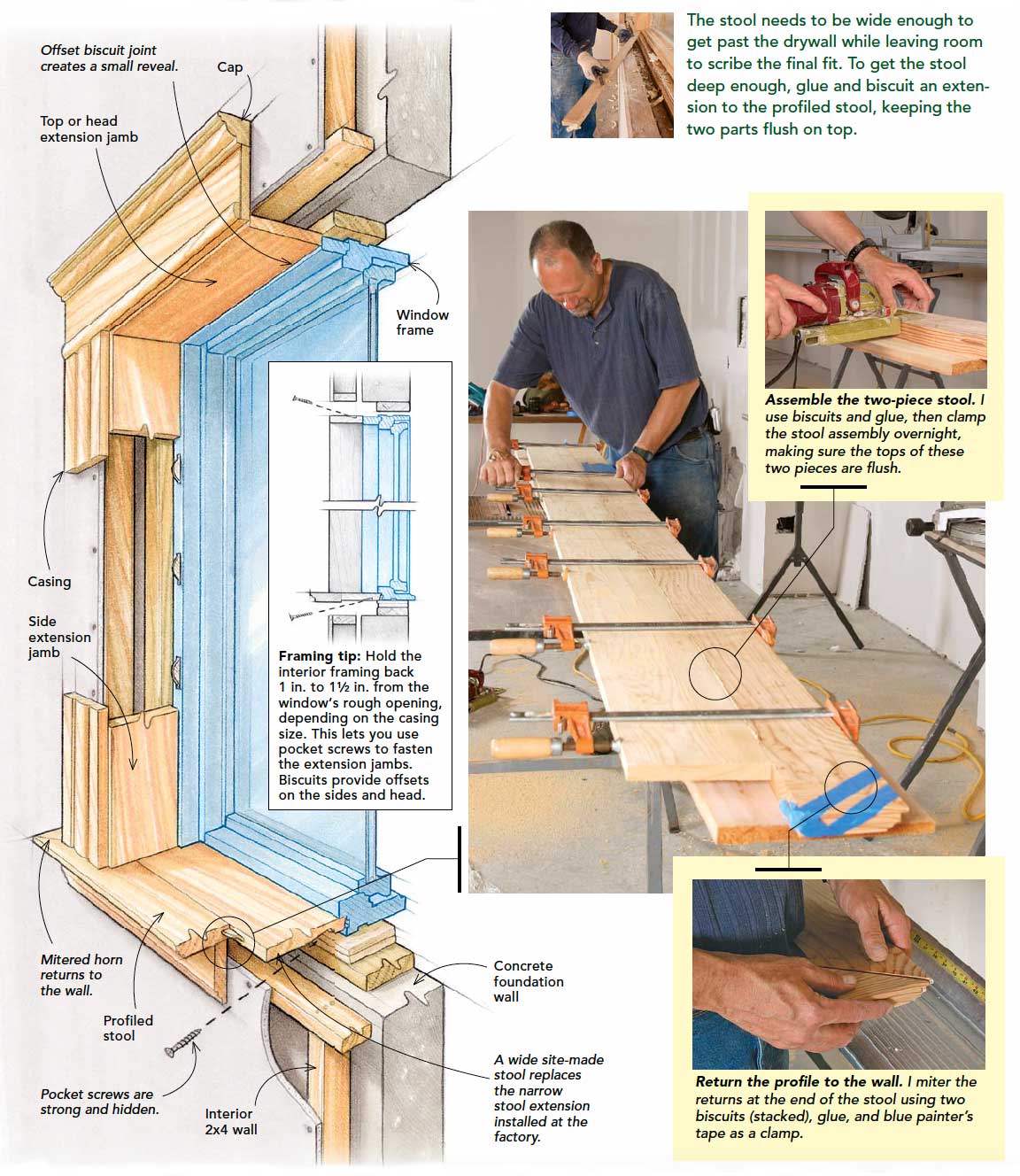

Synopsis: Montana builder and remodeling contractor Chris Whalen displays his method for building out jambs to accommodate windows in thick walls. Chris starts by building a deep stool extension, then cuts and attaches the stool. Then, using biscuit joints, he attaches the top and side jambs with an offset. Finally, Chris completes the work by attaching the head casing.

Finish carpentry is the art of making rough stuff look good. Even trimming a window can be a challenge because it’s usually complicated by poorly aligned framing or uneven drywall. If things go well, you can tenderize the drywall with a hammer or shim the window into alignment. If not, the window jambs might need to be planed, the casing tweaked, or the miters back-beveled at odd angles. In the end, a bead of caulk is often needed to disguise the solutions.

Multi-unit windows in thick walls, such as the basement windows featured here, are prone to even more problems. For starters, even if the windows were installed plumb, level, and square, they might not be parallel with the finished wall surface, meaning that the side jambs need to be tapered. Second, the individual units might not be installed in a straight line, meaning that the stool needs to be tapered. Third, access between the window and the interior-wall framing could be limited, which reduces options for attaching extension jambs.

Remove the narrow stool extension, and build a deep one |

First, identify the problems

The three window units here are in an 8-in.-thick concrete wall. A 2×4 wall covered with drywall sits inside. Before casing is applied to a window like this, the jambs and the stool need to be extended.

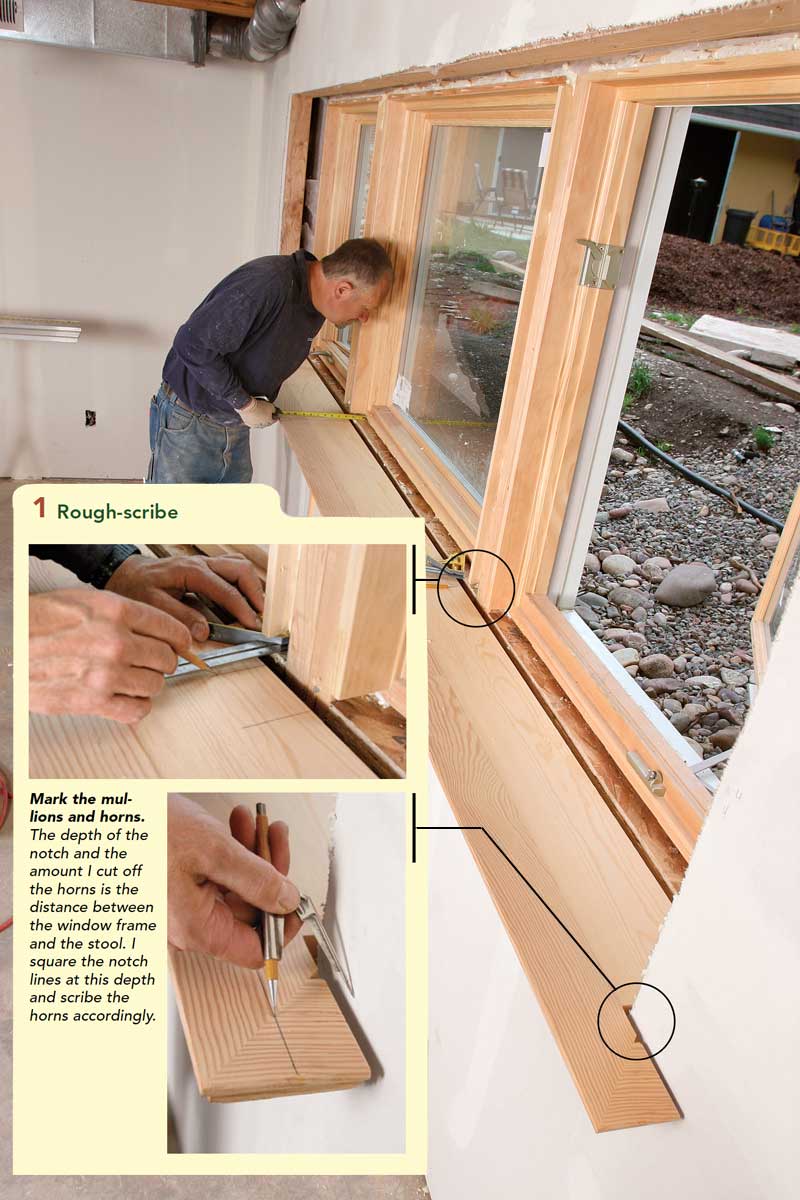

The first thing I do is determine how the window sits in relation to the drywall. With a multi-unit window such as this one, I place a long straightedge along the top and bottom jambs to determine if the units are in the same plane and at the same elevation. In this case, the windows were at the same height, but the center unit was pushed out in relation to the flanking units. Next, I straddle the corners of each window unit with a short straightedge on the drywall and measure from the window jamb. This tells me how wide the extension jambs will be and if tapering is required. For reference, I write the measurement on the drywall along the edge of the opening where the trim will cover it later. If the variation is less than 1 ⁄ 8 in., there’s no need to worry about tapering the extension jambs or stool. This discrepancy can be taken up by tipping the casing slightly. If the difference is greater than 1 ⁄ 8 in., the jambs need to be tapered.

Solutions start with the stool

Many windows have factory-applied 2-in. extension jambs that make the window suitable for a 2×6 wall. For basement walls, you need to extend the side and head jambs even more. I do this with a simple offset biscuit joint. This offset joint looks good on the jambs, but it’s impractical for a stool. That’s why I carefully remove the factory-applied stool extension and replace it with a new full-depth stool.

The new stool needs to fit between the rough opening in the framed wall while extending past the side casings. The overall length of the stool is the sum of the distance between the side jambs, the width of the casings, the casing reveals (typically 1⁄4 in.), and the amount of overhang beyond the casings. After cutting the stool to length, I miter the ends so that the profile returns to the wall. The extension is biscuited and glued to the back of the profiled stool. When this assembly is dry, I scrape excess glue, sand, fill gaps, and sand again, making it ready to install.

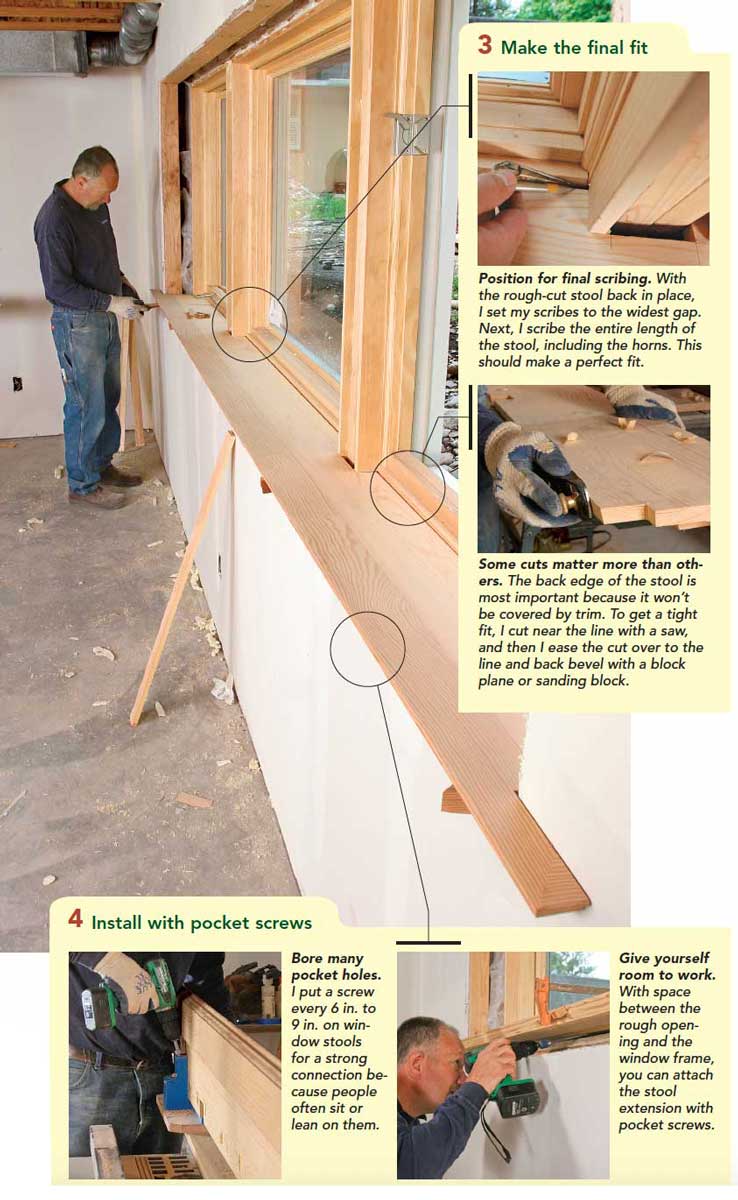

Set the new stool in the opening, and check its fit. The width will probably need adjustment. Because the three individual window units weren’t perfectly in line on this project, I needed to taper the stool in addition to notching around the mullions. I use a square and a scribe to measure and mark the notches and the ends of the stool extending past the window. After removing excess material with a jigsaw, I slide the stool into position again for final scribing and planing. Finally, I bore for pocket screws, clamp the stool into position, and screw it to the window frame. I use a lot of screws (every 6 in. to 9 in.) because someone is going to sit on this window stool sometime in the future, and I don’t want it to break.

Install jamb extensions with an offset reveal

For the head and side jambs, I add a piece to the factory extensions using an offset reveal of about 1⁄8 in. The head jamb needs to be long enough to pass the side jambs, but it does not have to be fit to anything else. I cut it slightly longer than the overall length of the window. To scribe the head jamb, I set it in place with bar clamps and shims. Next, I measure at a few spots to determine what needs to be removed from the jamb stock, and I set the scribe and mark along the length of the jamb. I cut to the scribe line with a small circular saw, then use a power planer, a block plane, and a sanding block to adjust until the fit is acceptable. As with the stool, the process takes a couple of fittings.

At this point, I use a biscuit joiner to create a consistent offset or reveal between the extension jamb I’m making and the one applied by the factory.

On the project here, because there wasn’t as much clearance between the window frame and the rough framing on top of the window as there was on the stool, pocket screws wouldn’t work. Instead, after applying glue and inserting the biscuits, I shimmed and nailed the head-jamb extension in place, making sure it was square to the side jambs.

The only difference in installing the side jambs is that the length needs to fit precisely between the new stool and head jamb. Rather than bending my tape measure into a corner, I measure in two steps: up from the stool 20 in., then down from the head to the 20-in. mark. I then add the two numbers together. I cut the jambs to length and then to width according to the numbers written previously on the drywall. Finally, I fit the pieces and then biscuit, shim, and nail them in place, making sure they are square and tight to both the head jamb and the stool.

The rest is standard procedure

The last few steps of the process aren’t much different than regular window trimming: Apply the mullion trim, casings, cap, and apron. I start with the mullions and work my way out. Using the same two-step measuring technique as I did with the side jambs, I measure the mullions, then cut and nail them in place.

I cut side casings to length, making them 1⁄4 in. longer than the distance between the stool and head jamb, thereby creating a reveal at the head. After nailing them in place, I measure, cut, shim, and install the head casing and cap. Before installing the apron beneath the stool, I permanently shim and block the stool so that it is level, straight, and solid. I then make an apron with mitered returns on the ends the same length as the head casing, and I nail on the apron so that its ends are in line with the outside edges of the side casings.

Whether you’re trimming a basement window or one in a double-stud, adobe, straw-bale, insulated-concrete-form, or any other thick-wall structure, these techniques ensure a quality installation for an appealing assembly.

Complete the assemblyThe trim detail here was dictated by the trim in the existing house. I begin with the mullions, which need to fit tightly between the stool and the head extension. The side casings are cut 1⁄4 in. long to establish the reveal for the head casing. The apron is installed last.   |

Chris Whalen is a partner in Black Mountain Company, a home-building, renovating, and woodworking firm in Missoula, Mont. Photos by Daniel S. Morrison.

From Fine Homebuilding #189