Tips for Staining and Installing Board-and-Batten Siding

There's more than one option for the best way to finish board-and-batten siding.

Writing to Fine Homebuilding‘s discussion forum, WenWS is looking for some advice on the best way to finish the board-and-batten siding for his new house. His plans call for 9 1/2-in. boards and 3-in. battens, which he says he’ll finish with a high-quality stain.

“Our original intention was to stain all boards, all sides before putting it up,” WenWS writes. “The house is 32 x 64 so this would be a big job, but we understood this to be best to seal the wood completely before installing.”

But in speaking with the owner of the mill that’s selling him not only the lumber but the stain, WenWS is told to install the siding and finish only the face, leaving the back side unfinished. This, he’s told, will “allow the pine to ‘breathe.'”

Priming the back side of wood siding, along with all edges and ends, has become standard advice, and WenWS is understandably perplexed by the advice. “It seems everything we do we get mixed message of how to do it the right way!” he says. “Any suggestions, reasons out there why we should do this one way or another?”

That’s the focus of this Q&A Spotlight.

Stain all surfaces of the siding

Despite what the mill owner has to say, Rdesigns recommends that WenWS stick with his original plan and coat all sides, edges and ends of the siding with stain.

“Assuming that you want the stain to also act as a preservative, and that the stain you use will be the type that is preservative, then you’d want to cover all sides and ends,” Rdesigns says. “No stain will entirely prevent wood from ‘breathing’–that is, allowing moisture to migratge into and out of the fibers.”

To make the work go faster, Rdesigns suggests WenWS build a shallow trough, line it with 6-mil plastic and dip each piece of siding.

“Have horizontal drying racks read to stack the boards for drying,” Rdesigns says. “and plenty of stickers to separate them as you stack.” If possible, Rdesigns adds, find a helper.

When installing the siding, he adds, be sure to stain any end cuts before the pieces are nailed up.

“You definitely want to coat all sides, otherwise the wood will curl badly,” adds DanH.

“The suggestion of a trough is a good one,” DanH adds, “but do this: Form up the trough with scrap lumber, landscape timbers, whatever, then add a ‘ramp’ off one side for about 3 feet. This can be plywood or just sticks of lath tacked between the trough form and some sort of elevated support (maybe stacked landscape timbers) on the other end.

“Cover the whole thing with plastic and begin staining. As the boards come out, set them onto the ramp (maybe on added lath strips, to hold the boards off the plastic),” he continues. “Let them drain for a minute or three on the ramp before moving to your stickered drying pile. You’ll save a lot of stain and have less mess.”

Florida suggests staining one side of each board before nailing it up, then stain the other wise and edges. “Keep on person staining and two installing,” he writes.

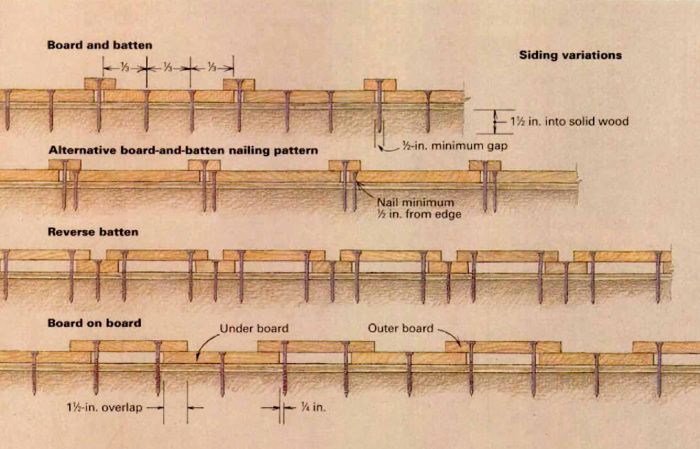

How board and batten is nailed also is important

In addition to applying stain to both sides and all edges, nailing both boards and battens correctly also is key.

Rdesigns suggests the “traditional method.”

“You nail through the batten to only one edge of the board and let the other board edge float under the next batten,” he writes. “This allows the width of the board to slide back and forth under the un-nailed batten as it will need to do when it expands and contracts with the changing seasons. This will great reduce splitting of the wide boards over time.

Calvin has a slightly different take.

“All the battens I’ve come across on old barns were nailed through the center of the batten–between boards,” he says. “This has always been my idea of the traditional method.”

He thinks the key is not to nail through any of the boards, and to use cut nails and native old growth timber, if possible.

Lots of old barns built that way are still standing.

Read the whole conversation at the Fine Homebuilding Forum.

View Comments

I really like it.. Well done

Great !