Making Cabinet Doors with Router Bits

The new generation of cope-and-stick bits will make frame-and-panel doors on site.

Synopsis: Readily available router bits can be used to make frame-and-panel cabinet doors quickly and accurately. This article shows the bits and explains how they are used. It includes a list of bit manufacturers and suppliers.

Until recently, you had to have a shaper to mill the cope-and-stick profiles commonly found in frame-and-panel doors. But no more. Several companies now make router bits that can cut cope-and-stick patterns for door frames, along with bits that shape the edges of the panels that fit into the frames. Armed with a set of these bits, you can make frame-and-panel doors (or any other millwork that requires a cope and stick, such as divided-lite window sash and wainscoting) with a hefty router mounted in a table.

You might ask, as did I, “So what?”

I work for a company that installs custom kitchens, and for the cabinets we make, we buy the doors from shops that make first-rate frame-and-panel doors for a very reasonable price. Quite simply, they can make them better and faster than I can. So it was with a large measure of skepticism that I tried a set of cope-and-stick router bits.

But after trying them out in my shop and consulting with other carpenters and woodworkers who have used cope-and-stick router bits, I’ve found three good reasons to own these bits. First of all, if the lead time from a big shop is too long to fit the job schedule, building your own cabinet doors can make economic sense. Second, doors from big shops are reasonably priced only if they are standard shapes — rectangles primarily, with the occasional arched top. If you want to make doors with some complicated shapes in them, these bits are a good way to do it. And finally, if you enjoy making cabinets for the fun of it, a set of cope-and-stick router bits will definitely expand your capabilities.

The stick and the cope

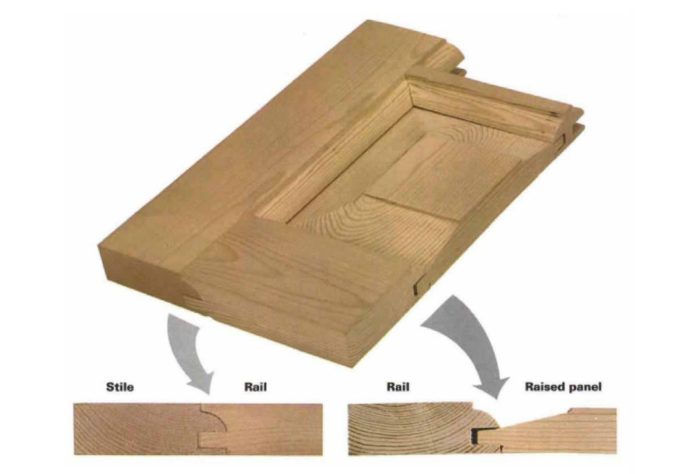

A set of cope-and-stick bits does three things: mills the groove for the panel, cuts a decorative profile around the inside edge of the frame and, at least in cabinet doors, cuts the joint that connects the stiles and the rails of the frame. The bits are, in fact, sometimes called stile-and-rail bits by the companies that sell them.

“Stick” is the term used to describe the profile of the frame that has the groove for the panel. The stick also includes the decorative profile — typically a radius or an ogee — that runs around the inside edge of the frame, setting off the panel. Stick profiles are milled into the inside edges of both the rails (the horizontal pieces of the frame) and the stiles (the vertical members).

The “cope” is the exact opposite profile of the stick, and it’s cut into the end grain of the rails. The result is a butt joint of sorts, where the rails meet the stiles. Structurally, the cope includes a short tenon that fits into the panel groove in the stick profile. This shallow mortise and tenon presents enough face-grain to face-grain contact for the glue to get a good grab on the frame parts.

For more photos and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

A House Needs to Breathe...Or Does It?: An Introduction to Building Science

Get Your House Right: Architectural Elements to Use & Avoid

Musings of an Energy Nerd: Toward an Energy-Efficient Home