Fast and Accurate Framing Cuts Without Lines

They didn't believe it, so I cut this one by eye and took out my square to see how close I came.

Synopsis: This article is aimed at veteran carpenters who are looking for ways to work more efficiently, in this case how to make a variety of cuts with a circular saw without stopping to measure or draw a line. A useful sidebar warns of kickback dangers.

Have you ever watched a professional chef chop vegetables? A blur of motion, the staccato sound of a knife on a cutting board, and a mound of neatly sliced carrots appears almost instantly. I always look for a fingertip among the carrots.

Some people have that same reaction when they watch me cut framing lumber—impressed by the speed, worried about safety. Like knives, circular saws are dangerous tools, but in experienced hands, a saw can be safely pushed to its limit.

I bought my first circular saw in 1951—a used worm drive for $85. I thought I’d died and gone to heaven. Suddenly, houses that used to take a week to frame could now be framed in a day.

But as the postwar demand for houses increased, so did the competition to build them. Surviving as a framing contractor meant more than just doing good work; it meant working fast, too. In the quest for efficiency, I began to depend less on my measuring tape and more on marking and cutting boards in place, less on my square and chalkline, more on my eye.

Just as ear training helps a musician to play an instrument, I trained my eye to help guide sawcuts. The saw became an extension of my arm, sort of like a bat in the hands of a professional baseball player.

The saw base lines up the cut

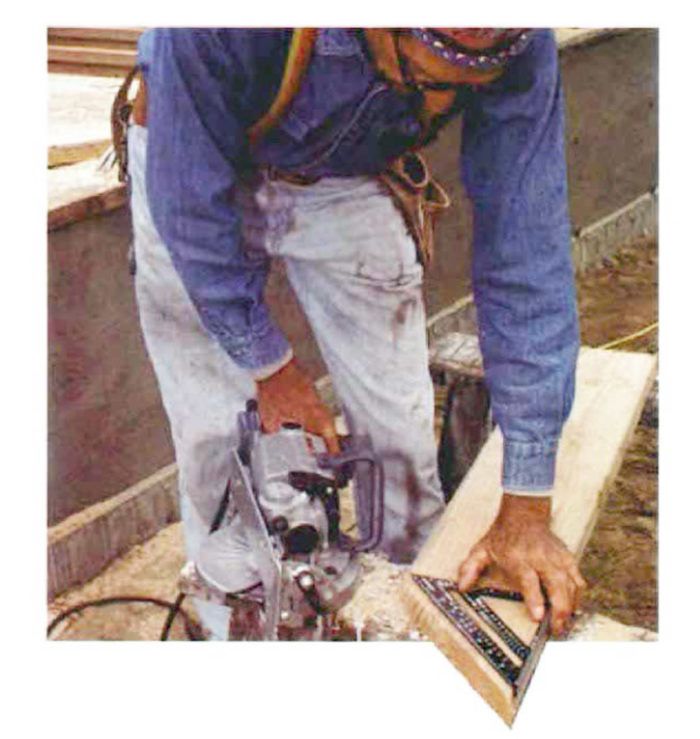

It takes literally a second to cut through a 2×4. But if you have to pull out a square and a pencil to mark a line to guide the cut after measuring and marking the length of the cut, and then put these tools back in your nail bag, the same cut takes you many times longer. Cutting square without drawing a line depends on the basic and oft overlooked premise that the saw base is a rectangle and that the side of the base is parallel to the blade.

For a square cut on a 2×4, just line up the front edge of the saw base parallel with the far edge of the board. The blade should now be perpendicular or square to the board, and a cut in that position should also be square.

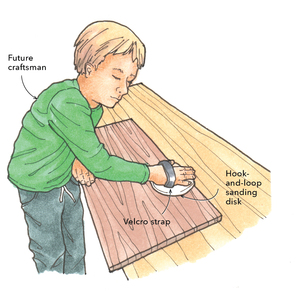

For wider boards, hold the guard up out of the way, tip the saw forward, and line up the saw base with the edge of the board. Now plunge through and lift the near edge of the board so that the weight of the saw helps you to finish the cut.The whole process still takes around a second and with practice becomes one fluid motion.While 2x4s or 2x6s can be cut safely with the board resting on your foot, the safest way to cut a wider board is to rest it on a 2x block.

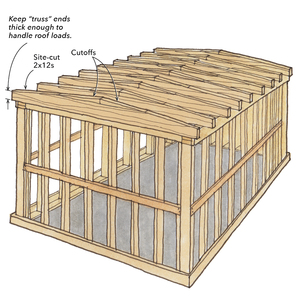

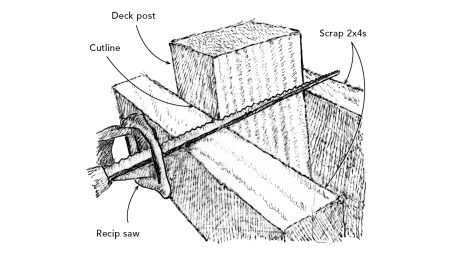

The same process is used when cutting a 4×4 post or header that is too thick for the saw to cut in one pass, as seen in the photo sequence at right. Once the first cut is made square, the saw kerf guides the next two cuts.

For more photos and information about framing cuts without lines, click the View PDF button below.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Portable Wall Jack

Sledge Hammer

Tajima Chalk Rite Chalk Line