Extended Tailgate: Lindsay Meacham, Tilemaker

This owner of Red Rock Tileworks in Nashville, Tenn., designs and manufactures environmentally friendly lines of handmade and custom tile.

At what point did you discover your passion for tilemaking?

My parents are both architects, and they instilled in me an appreciation for good design early on and have always encouraged me artistically. My first experience with clay was in an after-school class in third grade. After that, it was difficult to keep me out of the mud. My ceramics professor in college had us do a tile project, and it was at that moment when I realized I could connect my passion for clay and design with a career.

Are you driven by tradition, breaking from tradition, or both?

I’m inspired by tradition and feel that we offer some timeless designs that will never fade. When I first started making tile, this was really important to me because I wanted to be a part of history and lasting architecture. As I have evolved as an artist, I find myself looking more forward than backward. I reference different design movements but am much more comfortable putting my own stamp on them.

What inspires your handmade tiles?

I’m inspired by various cultures and traditions, but I like to add my own contemporary twist. Whether it’s the bright colors of spices in a Moroccan market or the gestural motions in graffiti on a subway wall, I always have my eyes peeled for new shapes and color combinations.

I just launched two new collections: Verge and Linea. Verge is rooted with natural elements but has a psychedelic twist. I photographed agate—a variety of quartz—and broke up the images like a kaleidoscope. I also played with watercolor and mimicked the veining of large Amazonian leaves. Linea is a very simple collection, and it reflects my love and respect for the simplicity and directness of midcentury-modern design. The lines of the tile can create more complex shapes depending on how they are installed. I present the tile in bright candylike colors, but they are available in any of our 62 glazes.

What is your creative process?

For each collection, my process changes and is quite spontaneous. Sometimes I sketch while I’m having lunch; at other times, I pour my brain power into geometry and perfection through graphic-design software.

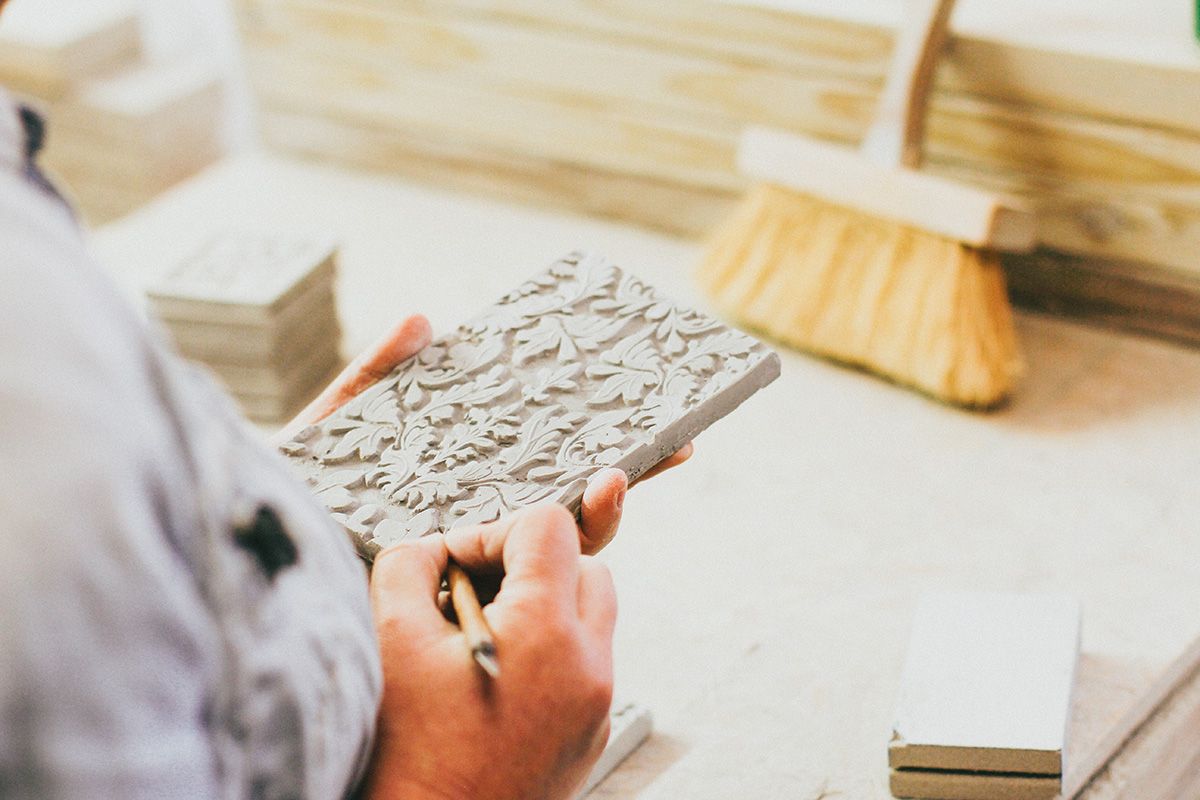

After I have a preliminary drawing, I carve in clay, plaster, wax—whatever suits the look. The designs evolve in this three-dimensional phase, as I start to understand how the glaze will play on the raised and lowered relief of the tile. Some designs just don’t translate from paper to clay.

Once I’m happy with the single tile, I make a master tile and a mold. I may decide to make slight changes if I foresee glaze issues, but for the most part, I’ve learned from my early tile-making mistakes and am purposeful with my prototyping.

Have you developed custom designs?

Yes. Typically our commercial clients come to us for custom tile, and it’s so much fun! Each client has specific ideas, but we try to offer insight into our medium in ways they may not have considered. Architects and designers sometimes share Pinterest folders, image files, or even CAD drawings of what they want. We then quote the project and get carving. Handmade tile has natural variation, so we try to emphasize this during the process. It’s part of what makes handmade tile so beautiful.

What are the advantages of boutique tile manufacturing?

Flexibility, response time, and uniqueness. Unlike those in mass-production factories, our molds are relatively inexpensive to make. If I see a trend or have a client who wants a specific look, I can make the tile in a matter of weeks. Imported tiles may be less expensive, but the time from concept to market can take months if not years. We can react quickly, and we can also craft for discerning clientele. Because we produce smaller runs, we can tailor to specific looks. Larger factories need to appeal to larger audiences, and this can sometimes water down the design.

Your operation is very conscious of the environment.

Ceramics is naturally a green process, and we take advantage of every green process we can. We do not deal with any toxic or harmful materials, and we make every

effort to recycle where possible. We recycle all of our wastewater, scrap clay, paper, and other materials. It’s nice to know that we can make something beautiful and not hurt this beautiful earth at the same time. [Swipe through the gallery to see installations of Lindsay’s work]

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Graphic Guide to Frame Construction

The New Carbon Architecture: Building to Cool the Climate

A Field Guide to American Houses