Trim Fastener Options

Brads, finish nails, and pin nails are the most common fasteners for trim work, but screws are useful when strength is a priority.

The types of fasteners typically used to install trim include nails, staples, and screws. Traditional hammer-driven finish nails are categorized by “penny” size—the larger the penny number the larger the nail. Pneumatic-driven nails are identified by gauge and length. The larger the gauge the smaller the diameter of the nail will be. Pneumatically driven staples work well for attaching plywood; however, due to the large hole created in the face of the material they are suitable only where they will not be visible.

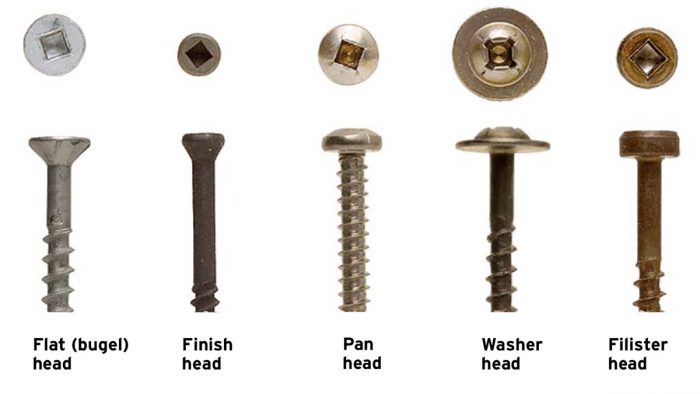

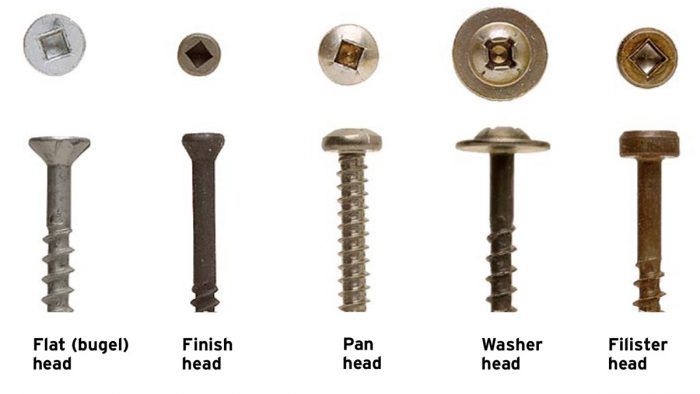

While screws are not very practical for installing all types of moldings they can offer certain advantages over nails with their ability to draw large moldings together for a tight fit. Installing and assembling moldings with screws also allows you to tweak the moldings to fit if necessary or to remove them with ease entirely. And using screws on a glued-up assembly often eliminates the need to use clamps. The screws I use for trim are either bugle head or common head and are chosen by the following characteristics:

Gauge refers to the overall diameter of the screw, the larger the gauge number the larger the diameter and strength. The larger gauges are also available in longer lengths. Number 8 or number 6 screws are a good size for most trim and general assembly work.

The length of a screw for a particular job can be determined by this rule of thumb: Two thirds of the screw’s length should protrude into the surface being fastened to.

Drive types useful for trim work are the Phillips and the square drive. I don’t even bother with the slotted drive, as they are difficult to use with a power driver. While both Phillips and square drive work well, the latter more firmly engages the driver bit, reducing slippage and stripping. The size of the driver bit varies with the screw gauge from #0 to #4 with #2 being the most common.

Screw heads commonly used for installing trim are the flat, pan, and trim head. Flat heads are used for general fastening. The head is either kept flush to the surface of the wood or countersunk and plugged. Pan heads are flat on the bottom surface of the head and are generally used for attaching hardware. They are also used almost exclusively for pocket-screw joinery. Pocket hole screws are sometimes available in fillister head or washer head styles. The washer prevents the screw from penetrating too deeply into soft woods. Trim head screws have a very small head much like a traditional finish nail. They are driven below the surface of the wood leaving a hole to be filled. There is a new version of these designed for installing composite decking that I have had great success with for fine adjustments of trim.

Excerpted from Trim Complete: Expert advice from start to finish by Greg Kossow

Available at Amazon.com.