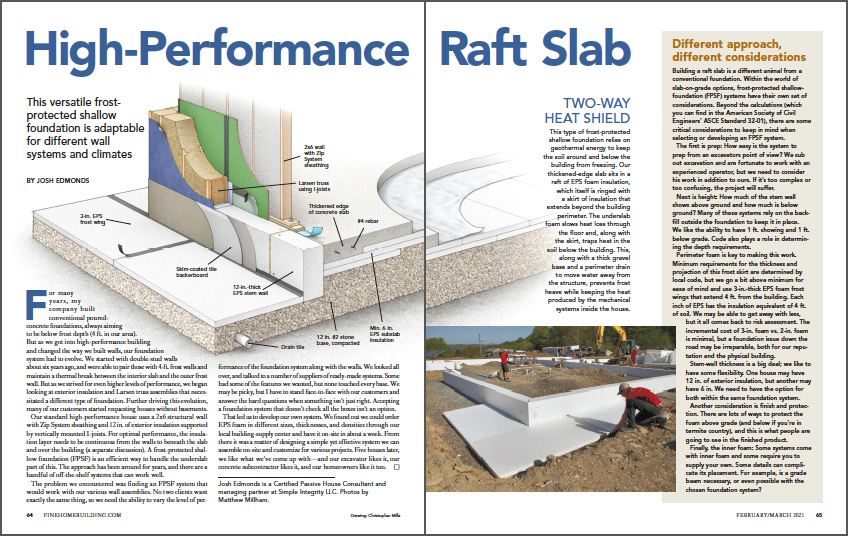

High-Performance Raft Slab

This versatile frost-protected shallow foundation is adaptable for different wall systems and climates.

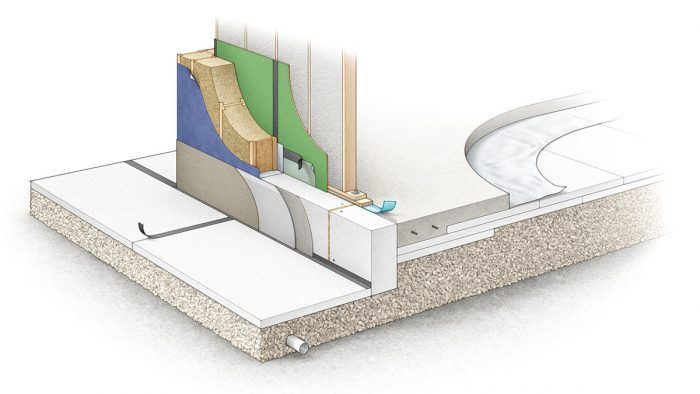

Synopsis: This type of frost-protected shallow foundation (FPSF) relies on geothermal energy to keep the soil around and below the building from freezing and heaving. This article details the assembly of an EPS foam raft that is ringed with a skirt of insulation extending beyond the building, from laying the stem walls and frost skirt, to roughing in the mechanicals, to filling with foam and finishing the concrete stem walls.

For many years, my company built conventional poured-concrete foundations, always aiming to be below frost depth (4 ft. in our area). But as we got into high-performance building and changed the way we built walls, our foundation system had to evolve. We started with double-stud walls about six years ago, and were able to pair those with 4-ft. frost walls and maintain a thermal break between the interior slab and the outer frost wall. But as we strived for even higher levels of performance, we began looking at exterior insulation and Larsen truss assemblies that necessitated a different type of foundation. Further driving this evolution, many of our customers started requesting houses without basements.

Our standard high-performance house uses a 2×6 structural wall with Zip System sheathing and 12 in. of exterior insulation supported by vertically mounted I-joists. For optimal performance, the insulation layer needs to be continuous from the walls to beneath the slab and over the building (a separate discussion). A frost-protected shallow foundation (FPSF) is an efficient way to handle the underslab part of this. The approach has been around for years, and there are a handful of off-the-shelf systems that can work well.

The problem we encountered was finding an FPSF system that would work with our various wall assemblies. No two clients want exactly the same thing, so we need the ability to vary the level of performance of the foundation system along with the walls. We looked all over, and talked to a number of suppliers of ready-made systems. Some had some of the features we wanted, but none touched every base. We may be picky, but I have to stand face-to-face with our customers and answer the hard questions when something isn’t just right. Accepting a foundation system that doesn’t check all the boxes isn’t an option.

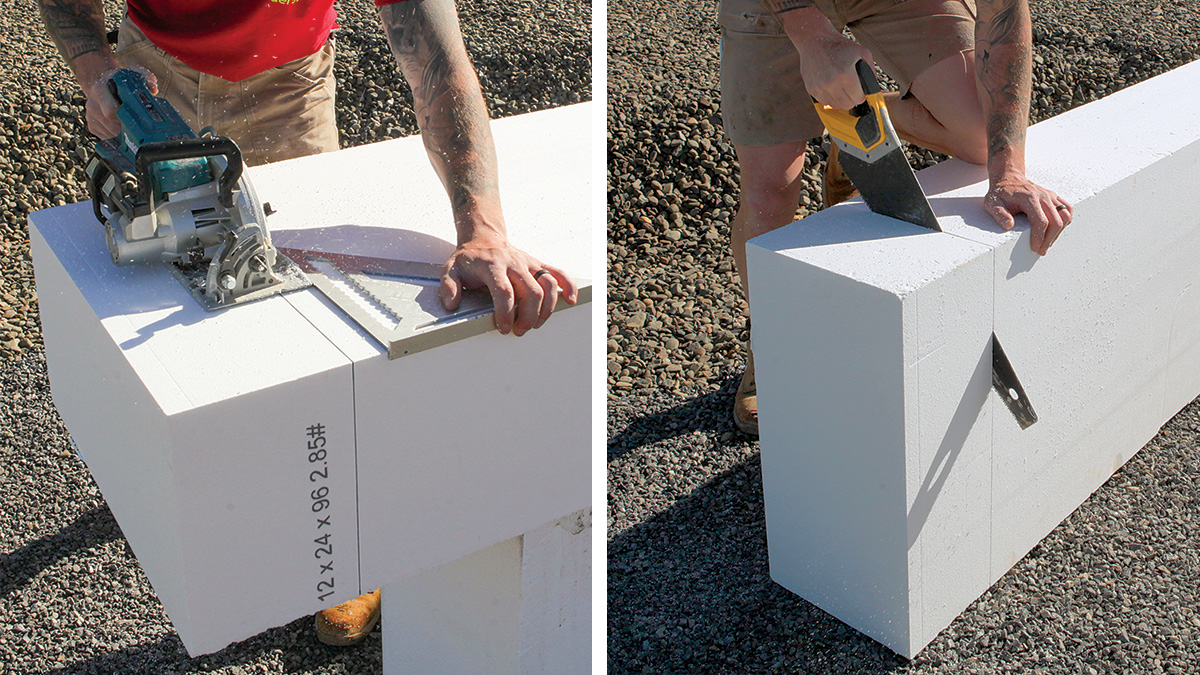

That led us to develop our own system. We found out we could order EPS foam in different sizes, thicknesses, and densities through our local building-supply center and have it on-site in about a week. From there it was a matter of designing a simple yet effective system we can assemble on-site and customize for various projects. Five houses later, we like what we’ve come up with—and our excavator likes it, our concrete subcontractor likes it, and our homeowners like it too.

From Fine Homebuilding #297

To view the entire article, please click the View PDF button below.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Foam Gun

Insulation Knife

Disposable Suit

View Comments

This is a DIY version of WarmFörm. It would be great to get a price comparison between the two methods, including labor.