Building Sturdy Sawhorses

Learn how to easily build a pair of simple, stackable sawhorses.

I once had a coworker who described his favorite sawhorses as Clydesdales. It was an appropriate name since his bulletproof horses seemed as heavy as their 1000-lb. namesake. Another coworker had the opposite approach. He favored lightweight sawhorses made from six equal-length pieces of 2×4. He could bang a pair together in the time it takes to roll out an extension cord.

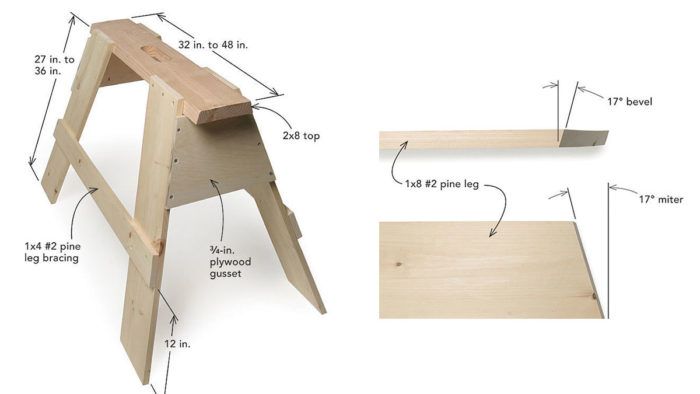

I think the best sawhorses are a combination of these two approaches. The best design I’ve found is the easy-to-build “Stackable site-built sawhorses” from Ty Simmons of Fort Laramie, Wyo.

I like Ty’s horses because they’re lightweight and strong, and use common materials. You could build them with only a circular saw, but using a tablesaw for beveling the top and a sliding miter saw for cutting the legs makes the process much easier. Including setup, it took me about 90 minutes and cost me $50 in materials to make the pair of horses featured here.

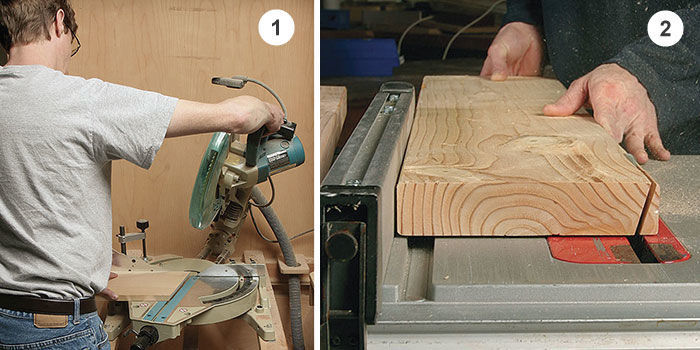

1. Cut the legs.

All legs have a compound angle on both ends. With the miter and bevel both set at 17°, cut four legs (for a pair of horses) so that the finished leg has the same cut on both ends. Leaving the bevel setting alone, rotate the miter table to the other 17° mark on the other side of 90°, and cut the other four legs.

2. Bevel the top.

Rip a 17° bevel on both sides of the top. You can do this with a circular saw, but a tablesaw with a rip fence is faster and easier.

3. Fasten the legs.

Mark the top 3 in. from the end at all four corners. Hold the leg flush to the top, and drill the pilot holes with a twist or pilot/countersink bit. Then drive the screws. Use 11/2-in. #10 wood screws because they have greater shear strength than deck or drywall screws. Trim one of the tops later if you want the horses to stack.

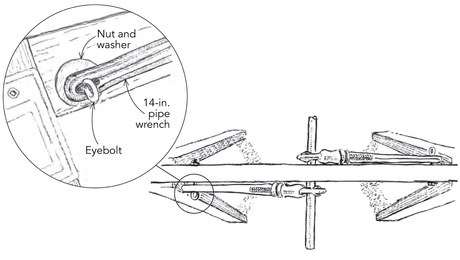

4. Install the bracing.

Mark the legs 12 in. up to locate the 1×4 leg bracing. Hold or clamp the board in place, and scribe both ends to match the leg angle. Drill the pilot holes, and drive the screws.

5. Scribe and cut the gussets.

Clamp or hold the gusset in place while you drill pilot holes. Be sure to align the drill bit carefully so that the hole stays in the center of the leg. After you run in the screws, your team of horses is ready for work.

6. Almost done.

Clamp or hold the gusset in place while you drill pilot holes. Be sure to align the drill bit carefully so that the hole stays in the center of the leg. After you run in the screws, your team of horses is ready for work.

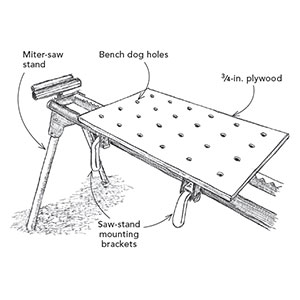

Four more options

Consider these alternatives when space is tight or time is short.

Site-built

Space Saver – Built from 20-in. by 32-in. scraps of 3/4-in. plywood, these clever knockdown sawhorses are surprisingly sturdy. The 3/8-in.-deep mortises in the 2×6 top are made with a circular saw and a sharp chisel.

Get ‘er done – Made from six 32-in. pieces of 2×4, these are the horses to build when you’re in a hurry. You can use gun nails if time is extra tight, but 21/2-in. screws hold better and come apart easier when it’s time for your steeds to become blocking.

Store-bought

Fast, rock solid, but expensive – Trojan’s nearly indestructible TS series is the best commercially produced sawhorse, but you’ll need to shell out $90 per pair for the 27-in. version. The 35-in. model costs another $12 per pair.

A popular option – Available at home centers everywhere, these sawhorses ($60 per pair) have selfleveling, adjustable legs that keep the horse steady on uneven terrain, but it’s easy to lose the leg extensions and the bolts that secure them.

Photos by Rob Yagid

View Comments

Build and Install a simple tool tray across the leg supports ----- and you've got a home for the holidays kinda feel.