Q:

A carpenter I work with wants to build a set of closed, or housed, stringer stairs for his house. He wants to rout the stringer to fit the treads and risers exactly and does not see the need for a tapered groove and wedges. I say the tapered grooves ease installation and guarantee a tight fit on the visible side of the stringer. Who’s right?

Tim Hogan, Madison, WI

A:

Andy Engel, former executive editor of Fine Homebuilding and author of Building Finish Stairs , replies: As a stairbuilder, I routed tapered mortises in my stair stringers for several reasons. Not owning a thickness planer, I didn’t mill my own treads and risers, but rather bought the stock as needed. Consequently, the thickness of the treads and risers varied slightly with each new batch of lumber. If I had routed a parallel-sided mortise, I’d have had to make a new router jig for each thickness to ensure a tight fit. I’m far too lazy for that. In addition, the same tapered mortise jig accommodates a range of stock thicknesses, such as 1/2-in. thick instead of 3/4-in. thick risers.

And you are correct that tapered mortises ease installation and guarantee a tight fit on the visible side of the stringer. Another advantage of tapered mortises is that you don’t have to glue the top edge of the tread or the front edge of the riser to the stringer, so glue squeeze-out in these highly visible spots is controlled easily. Instead, I used a ton of glue on both sides of each wedge so that glue literally would be dripping out (on the hidden underside) after the stairs were assembled. And I never had a callback for squeaky stairs.

Plus, routing a tapered mortise is no harder than routing a straight mortise. The only extra work is cutting the wedges, a task that takes about 20 minutes per stair, less if you’re cutting wedges for several stairs. I’d rather cut wedges than scrape squeeze-out any day.

Some folks claim that the wedges take any cup out of the treads and risers, but in my experience, trying to take the cup out of a 5/4 tread or a 4/4 hardwood riser with a wedge is a dicey proposition; sometimes it works and sometimes it doesn’t. I wouldn’t tout it as an advantage of this stair-building method.

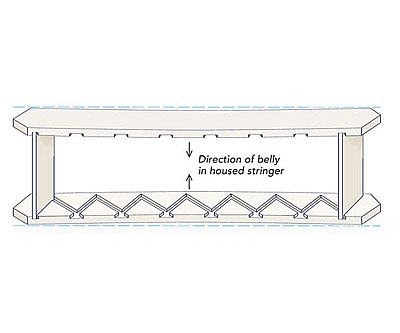

I have built a few open-riser stairs with parallel-sided mortises, and in those cases I found it necessary to screw every tread to the stringers. But mechanical fasteners aren’t needed with tapered mortises and wedges—with the exception of the top and bottom treads, which I install first to square up the stair. The trick is to sight the stringer stock before routing and to arrange the stringers so that any bellies in the stock face each other. That way, with the top and bottom treads firmly seated, the inward curves of the stringers make the rest of the treads and risers squeeze tightly into place between the stringers. And the opposing bellies in the stringers just about guarantee a straight stair.