Synopsis: This article explains how to repair old-fashioned double-hung windows whose sash operation is aided by hidden weights.

I get a lot of calls from clients who want me to replace their windows. Often the old windows are wood sash that have been neglected and are on the verge of falling apart. And sometimes I’m hired to yank out a wall of replacement metal windows that clash with the style of the house. There are many instances, however, when it’s best to restore the original windows to working order. This was certainly the case with John and Nina Heaths’ recently acquired home. Located in the elegant Hancock Park district of Los Angeles, the house was originally constructed in 1923 by the contractor who built many of the fine surrounding dwellings.

The house was structurally sound, but it had suffered many remodels and lost a good deal of its original refinement. And a lot of things didn’t work—like 30 double-hung windows.

Windows with a twist

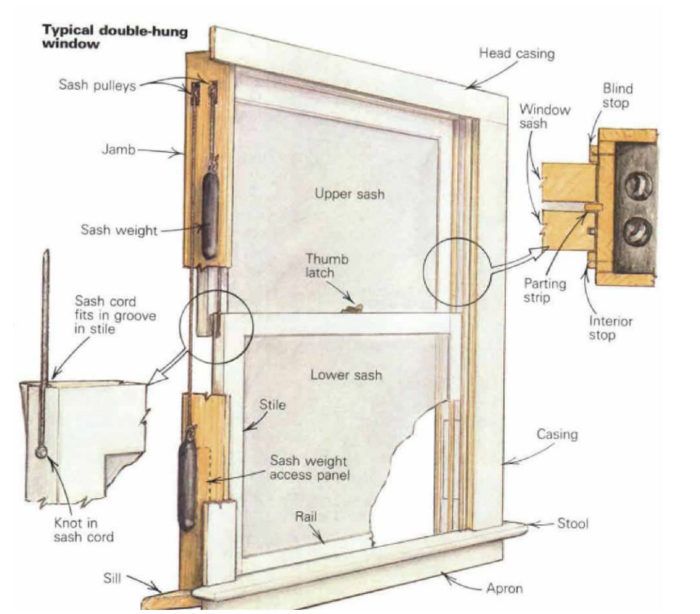

The windows appeared to be regular old-fashioned double-hung sash of the type popular from the turn of the century to the second World War. They were equipped with cords, pulleys and iron weights for counterbalance. A traditional thumb-latch secured the upper and lower sash and a recessed brass finger-pull assisted in raising the lower sash. But unlike other double-hung windows that I had worked on, this finger-pull had a small knob in its center, the significance of which I would soon learn. A closer inspection revealed nice touches. All the interior stops were secured by screws rather than by the usual finish nails.The left hand parting strips were affixed with flathead screws, a clue that dismantling should proceed from that side.

Most of the windows were painted and caulked shut, but I found one that could still be opened. When I lifted the lower sash, I was surprised to find a split sill containing a recessed wooden bar. A spherical-headed screw protruded from the bar, and when I pulled on it with a pair of pliers the wooden bar revealed itself as the top rail of a concealed window screen. I now understood the function of that knob in the finger-pull: it operated a claw mechanism that clasped the screw protruding from the screen frame. A 90° turn released the screw so the sash could be opened without the screen. The upper sash had a mechanism with a similar device. I was working on a houseful of windows with retractable screens.

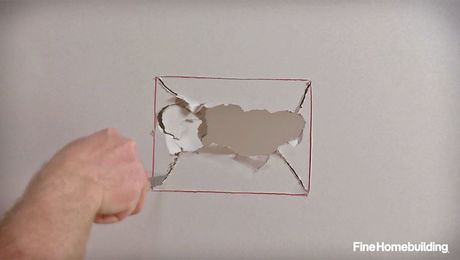

It took me two hours to partially dismantle the first window. As it turned out, nearly one man-day was needed to return each window to full working order. Although the retractable screens presented special problems, the steps I took to rejuvenate the windows are similar to those required for all double-hung windows.

To learn how these windows were restored, and view diagrams, click the View PDF button below.