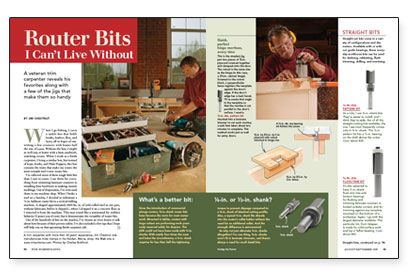

Router Bits I Can’t Live Without

A carpenter reveals favorites, and the jigs that make them handy.

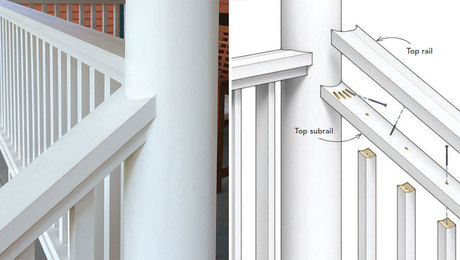

Synopsis: With the aid of simple jigs, the router and various bits can be used efficiently to do the work of chisels, drills, bandsaws, jointers, tablesaws, shapers, molders, jigsaws, Skilsaws, and planes, and a host of other tools. In this well-illustrated article, a veteran trim carpenter offers an overview of his favorite bits. You’ll also learn how to rout hinge mortises, cut outlet holes in baseboard, make dadoes for shelving, rout tapered flutes, and more.

When I go fishing, I carry a tackle box that holds hooks, leaders, flies, and lures, all in hopes of outwitting a few creatures with brains half the size of a pea. Without the box, I might as well stay at home with a ham sandwich, watching reruns. When I work as a finish carpenter, I bring a similar box, but instead of hope, hooks, and Hula Poppers, this box contains the items that make my router the most versatile tool I own: router bits.

I’ve collected more of these tough little bits than I care to count. I use them for everything from trimming laminate counters to installing door hardware to making custom moldings. Out of desperation, I’ve even used them in my machine shop. When I broke a tool on a Sunday, I decided to substitute a 1⁄2-in. bullnose router bit in a vertical milling machine. It shaped approximately 6000 lin. in. of cold-rolled steel in one pass, without lubricant, before it chipped — when I dropped it on a concrete floor as I removed it from the machine. This may sound like a testimonial for reckless behavior (I assure you it’s not), but it demonstrates the versatility of router bits.

Out of the hundreds of bits on the market, I’ve chosen an even dozen to talk about here because of their proven utility. I’ve also included a few tips that I hope will help you on that upcoming finish-carpentry job.

What’s a better bit: 1⁄4-in. or 1⁄2-in. shank?

Since the introduction of commercial plunge routers, 1⁄2-in.-shank router bits have become the norm for most router work. Mounted in tables, routers with large cutters are performing work previously reserved solely for shapers. This shift could not have been made with 1⁄4-in. shanks. With nearly four times the mass and twice the circumference, a 1⁄2-in. shank requires far less than half the tightening torque to prevent slippage compared to a 1⁄4-in. shank of identical cutting profile. Also, a typical 1⁄2-in. shank fits directly into the router’s collet holder without the need for an additional collet. And the strength difference is astronomical. So why not just eliminate 1⁄4-in. shanks altogether? For one thing, 1⁄2-in. shanks won’t fit in laminate trimmers, and there’s always a need for small detail bits.

For more photos, drawings, and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

BOSCH Compact Router (PR20)

All New Kitchen Ideas that Work

Metabo HPT Compact Cordless Miter Saw (C3607DRAQ4)