The Glue Sled

Apply construction adhesive with precision using a simple, self-made glue sled.

Call me persnickety, but I like to place a nice full bead of construction adhesive down the center of the floor joists before I lay down a sheet of plywood subflooring. Too many times, I’ve been on a job site where the glue was applied carelessly, resulting in an erratic line with skips and unacceptably thin smears.

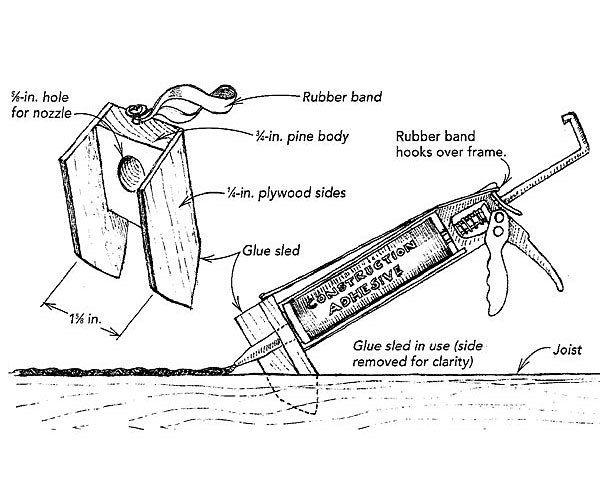

If it’s worth the expense and effort of gluing a subfloor in the first place (and I think it is), then it’s worth taking the time to do it right. The device shown in the drawing is my solution to the problem. I think the best part is that using this gadget, I center the glue bead on the joist every time without having to go back.

The glue sled, as I call it, is nothing more than a 1-5/8-in. wide block of 3/4-in. pine with a hole in it. The block is sandwiched between 1/4-in. thick plywood sides. The hole accepts the nozzle of the glue cartridge, and the rubber band loops over the caulk-gun frame, holding the sled in place. In use, the plywood sides ride along the sides of the joist, keeping the nozzle centered.

I think a 3/16-dia. bead of glue is the ideal amount. And although I don’t obsess over this detail, I can tell you that cutting the nozzle 3/8 in. from its tip yields a 3/16-in. opening for the glue to exit. If your joists are on 16-in. centers, figure on using about three-quarters of a 10.5-oz. tube per sheet of plywood. Where sheets come together on one joist, you can get a fairly even off-center bead of glue by lifting up the sled and angling the glue gun to the side.

— Herrick Kimball; Moravia, NY

From Fine Homebuilding #146

RELATED STORIES

- Assemble Housed Stairs With Construction Adhesive

- A Guide to Subfloor Sheathing

- What’s the Difference: Construction Adhesive

Got a Tip?

Do you have any great tips like this one on how to precisely apply construction adhesive with a DIY glue sled? Share your methods, tricks, and jigs with other readers. Tag them @FineHomebuilding on social, email them to us at [email protected], or upload them to FineHomebuilding.com/reader-tips. We’ll pay for any we publish.

View Comments

Persnickety!

Genius! Have 10,000 plastic ones made (which means the glue won't stick to them) and market it. I'd buy one.

Make the sides adjustable for I-joists or open web joists. Or make others with wider flanges and those may have offset holes for the multiple sheet joists.