Build a Custom Range Hood

Add a distinctive detail to your next kitchen with a curved-hood fan cover.

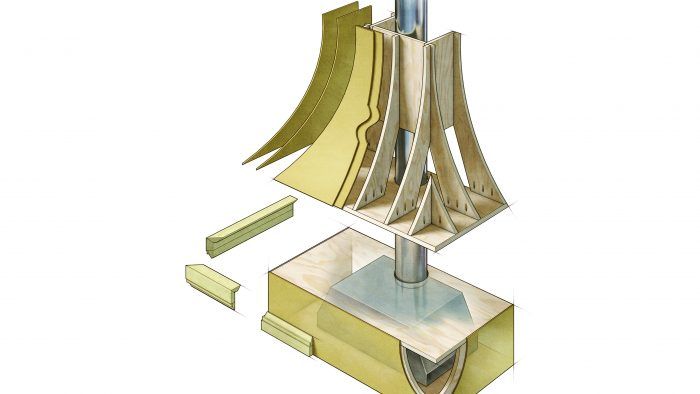

Synopsis: This article describes how to build a custom range hood, from drawing the curve on a plywood template, to building the curved framework with braces and pocket screws, to finishing the chimney with MDF panels and trim. The article includes a detailed drawing of the range-hood elements and their dimensions.

As the shop manager at a design/ build firm, my role is more than cabinetmaker. I consult with the design team, manage and mentor the shop crew, purchase tools and materials, and even decide when it’s best for us not to build things ourselves. This kitchen is an example of a project where I played all of those roles. The cabinets are supercustom, and, with inset doors and drawers, are among the trickiest cabinets to build. Though we made most of these cabinets in the shop, I knew that we’d need to save some time, so we ordered the drawer boxes and some of the doors. But I decided to build the range hood in-house even though we hadn’t built one before. We certainly could have bought a similar range hood, but it wouldn’t have matched the rest of our design so nicely. And we could have had it made in a CNC shop, but that would have been costly. Since there are no expensive materials involved—the paint-grade range-hood cover is mostly plywood and MDF—we decided to go for it. We took our time and everything worked out well. Having now built a second version of this hood design, I have some helpful tips to share. In fact, I hope to build a stain-grade version soon, with wood veneer over the curved chimney.

To view the entire article, please click the View PDF button below.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Anchor Bolt Marker

100-ft. Tape Measure

Plate Level

View Comments

Great article, superb craftsmanship, well executed. No complaints there.

However, speaking from a purely practical standpoint, this isn’t a great design for a working kitchen. I installed a range hood in our current kitchen that has a similar slope for the chimney portion as the hood in the article, but luckily my hood is stainless steel.

As any cook can tell you, the surfaces adjacent to a cooktop inevitability get covered in oil/grease, which in turn traps dust, pet hair, and anything else floating by. Backsplashes and counters are easily accessible and therefore get frequent cleanings, but things like range hoods—that typically require a step stool or ladder—get cleaned much less often. The greater the slope in the hood, the more grease/dirt it accumulates.

By the time the homeowner gets around to tackling this cleaning chore, the range hood will appear to have a layer of carpeting on it. Out come the harsh cleaners and scouring pads, and a painted surface like the one in the article won’t last long. There is a reason why busy cooks prefer metal range hoods. (Don’t be fooled into thinking that the exhaust fan will catch and exhaust 100% of the grease/oil produced when cooking. Some will always escape, and that’s assuming the cook remembers to use the exhaust fan. Which they won’t.)

The range hood that Cliff Ham built for this FH article looks amazing, but would best relegated to homeowners who prefer the look of a trophy kitchen, but don’t actually cook.