Tile a Barrier-Free Bathroom: Waterproof Membrane

After Tom Meehan sets the linear drain, he demonstrates how to install all of the components of a modern tile-underlayment.

A great looking mud job is not enough to keep the water in the room. Cement is porous and needs to have a water-proof membrane to contain the water. Not only does it need to cover the floor, but it needs to go at least six inches up the wall. This makes the whole room one big shower pan. On the shower walls, even though I have cement board, many times I apply the membrane up to the shower rod. It may be a little over kill, but this shower stall won’t have a curb or a door to keep water in, and extra protection against water intrusion is always a good idea.

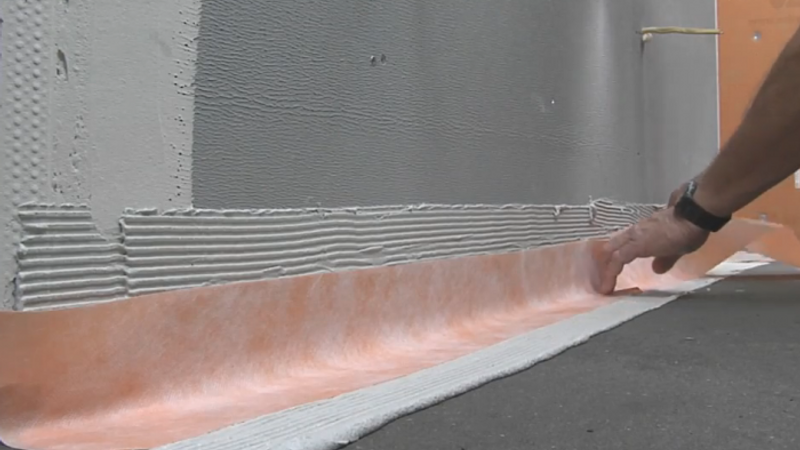

The water-proof membrane that I am using here is called Kerdi and it is made by the Schluter Systems Company. It is almost paper thin and very easy to work with. It is applied with non- latex mortar. The cement that I used is called Ditra-set and made by the TEC Products Co. It has a little more body in than the normal non latex thinset cement and works well with this type of membrane. The cement is applied with a 3/16-in. v-notched trowel.

To start, I use a 6 inch band and fold it to the wrap the complete border of the room where the floor meets the wall. Three inches on the wall and three inches on the floor. I spread the cement and apply the band. I then use a taping knife and push the membrane flat and push out any excess cement. This is very similar to taping a joint when sheet rocking walls and taping the vertical corners. Next, I cut and do a dry layout of the membrane for the floor. The membrane comes in rolls that are one miter wide (39 ½ inches). Any where the Kerdi has a seam, I give it a full two inch overlap, especially on the band where the floor meets the wall. To bond the over-lapping of the seam, I use the same thinset that I am bonding the membrane to the mud base with. It is also the same product that the tile will be bonded to the membrane with. This simplifies the whole installation process by no having to bring in different products as the project advances. The only other time that I would use a different thinset with this membrane is when I have to bond the membrane to a wood substrate, Then I would use a latex-modified thinset.

Continuing with the membrane installation process, Once each one meter section has been cut and laid out, I snap a line so I don’t over spread the thinset into the next section. Then I spread the thinset with the 3/16ths v-notched trowel again. I had rolled up the Kerdi membrane and I now start it on one end and slowly un-roll it exactly on the line keeping it straight over the mud that I had spread. It is important not to have any kinks in the membrane, so as I push from left to right (or right to left), I use my hands to carefully have the membrane flat, straight, and with no wrinkles. Once the Kerdi is in place, I use my flat 10” taping knife to push any excess thinset or air pockets out to the side. Once each section is done, I leave it to set over night.

View Comments

Schlutter says that you are supposed to put kerdi band over the waterproof membrane on the floor as well, 2" overlap of course. I didn't see that being done at the end