Wiring a Switch Loop

Learn the code-compliant method for wiring a switch when an outlet or fixture box is closer to the power source than to the switch box—plus see the way it was commonly done in the past.

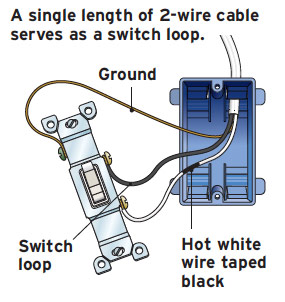

There are two ways of wiring a switch loop. The old-school way, shown in the first drawing below, can probably be found in 90 percent of homes but has been superseded by changes in the electrical code. The second way, shown in the second drawing below, conforms to the NEC requirements and should be used for new installations, particularly if you want modern devices on any given circuit to work properly.

The historical method

Before the code changed, it was common to run a single length of 12/2 or 14/2 cable as a switch loop. This means bringing the power down from the fixture to and through the switch and then back up to the fixture. As such, the white wire taped black in the 12/2 or 14/2 switch loop functions as the incoming hot wire, and the black wire acts as a switch leg to return the power to the fixture. Here, the white wire is actually a hot wire and is taped black to identify it as such.

Turn off the power and test to be sure. At the outlet or fixture box, splice all the grounds together. Attach the source neutral wire to the fixture neutral wire. Attach the source hot wire to the white wire (taped black) of the switch loop. Last, connect the switch loop black wire to the black fixture wire.

Note: Here, for convenience, we bend the rule of using a white wire only as a neutral wire and instead wind black tape on each end of the white wire to show that—in this case—the white wire is being used as a hot wire.

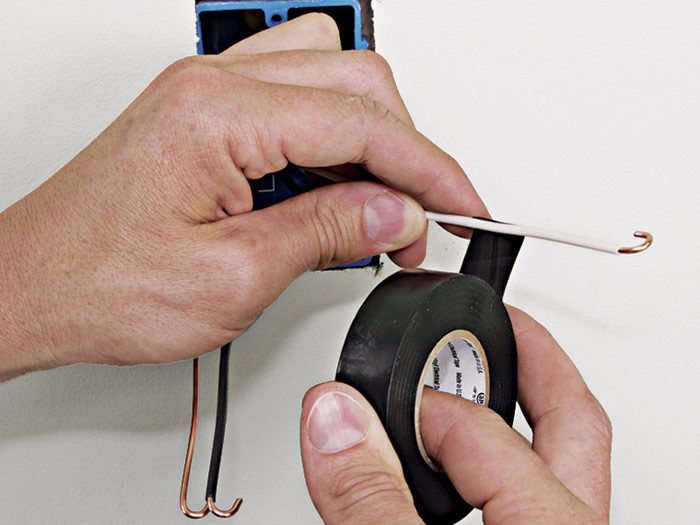

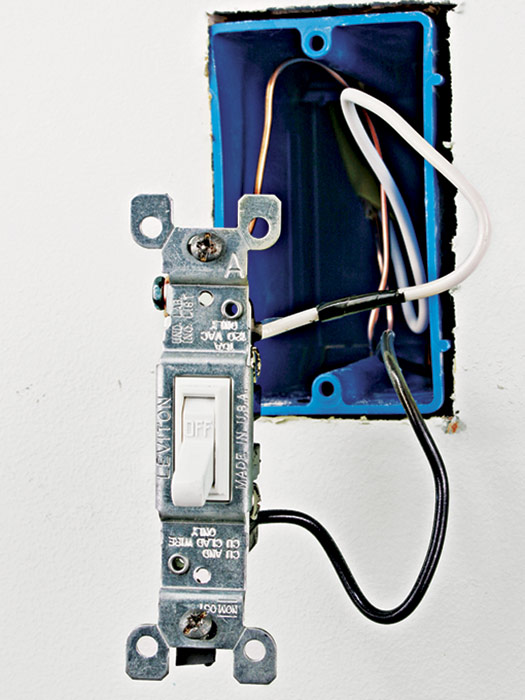

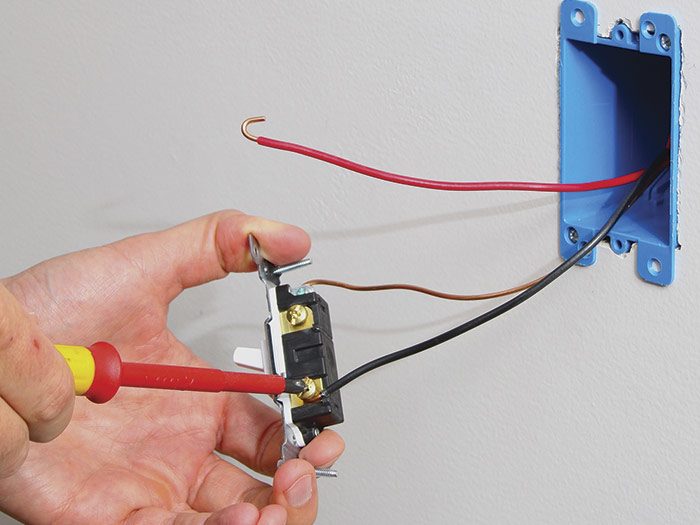

At the switch, start by stripping and looping the wire ends. Next, tape the white wire with black electrician’s tape to indicate that it is serving as a hot wire to the back-fed switch 1. The NEC dictates that the white wire in back-fed wiring is always the hot lead (power coming in). The black wire, on the other hand, is the switch leg that runs back to the fixture.

|

|

|

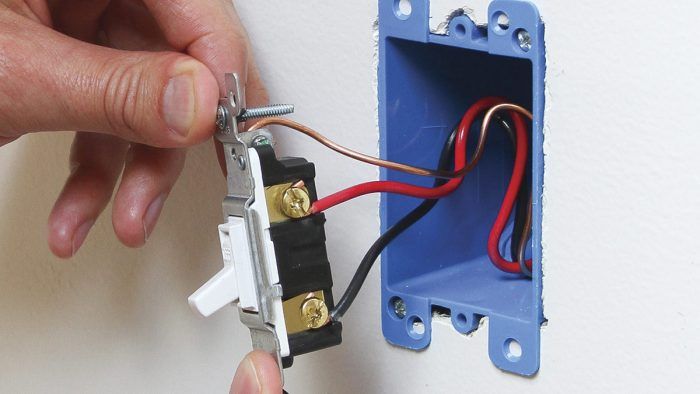

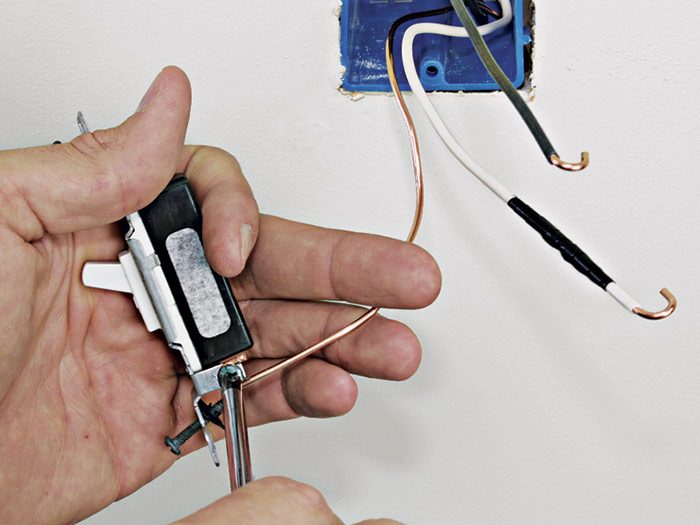

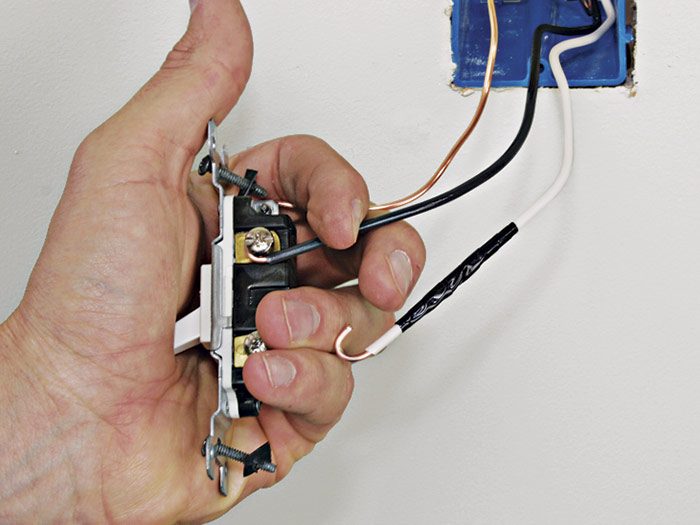

First, connect the ground wire to the green ground screw 2 on the back-fed switch. Next, connect the switch-leg wire (black) 3, then the hot wire (white taped black) to the switch terminals 4. To keep looped wire ends snug against the screw shaft as you tighten down the screw, pull gently on wires, as shown. Not fumbling with wire ends saves time.

Finally, tuck the wires into the box 5, screw the switch to the box, and install the cover plate.

|

|

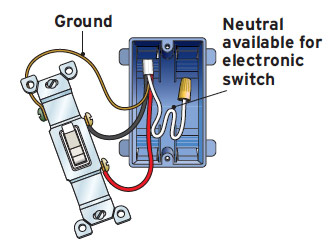

The modern method

This method of wiring a switch loop reflects recent code changes. Specifically, the NEC requires that there be a neutral in every switch box because some electronic timer switches and other energy-saving controls need a neutral. So if you want to use a switch-loop approach, you must use three-conductor (3-wire) cable. The neutral of the 3-wire cable must be connected to the neutral of the circuit, even if the neutral is not going to be used.

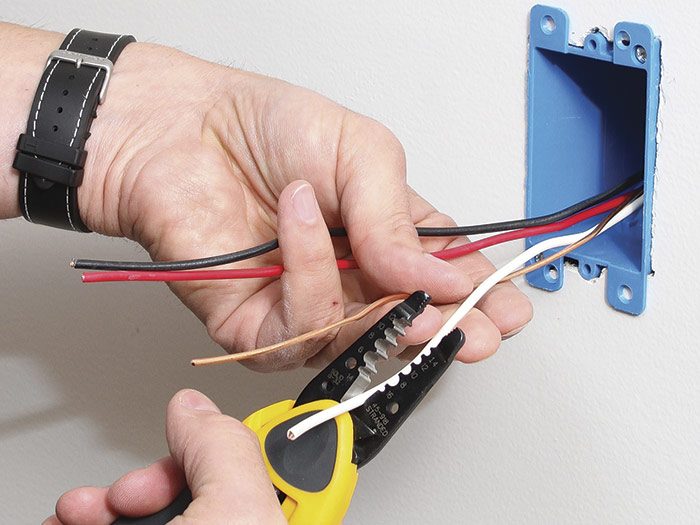

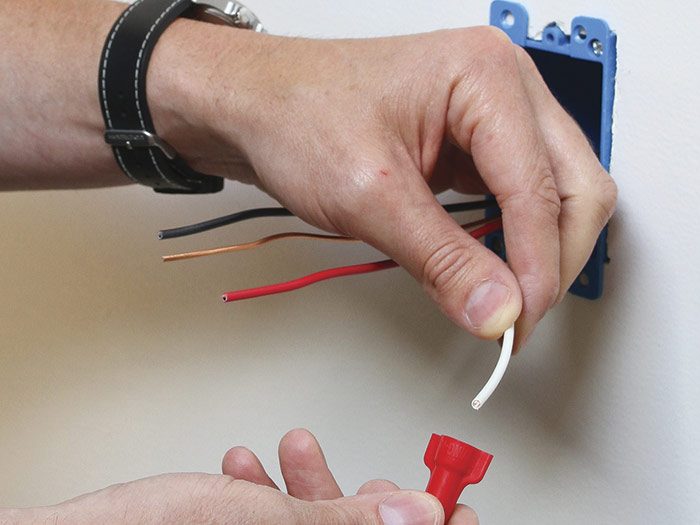

This installation sequence is done with the power off. From the power source at the fixture, run a length of three-wire cable to the switch box. Remove cable sheathing 1 and strip 3⁄4 in. of insulation from the ends of insulated wires. If the switch doesn’t need a neutral wire, cap the neutral wire 2 and fold it into the switch box.

|

|

|

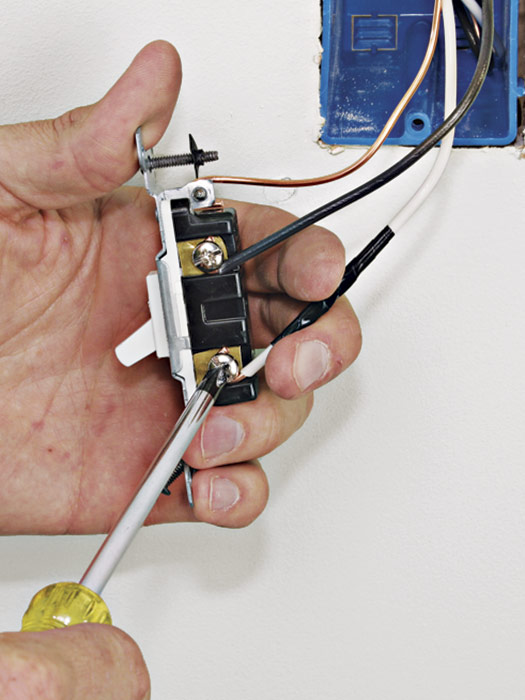

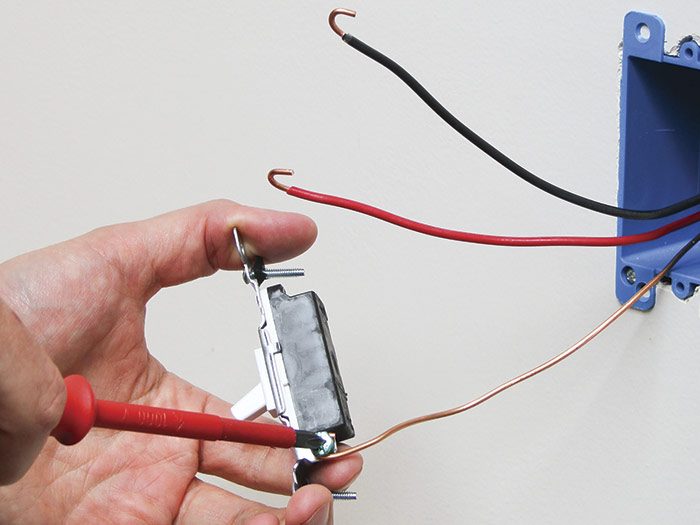

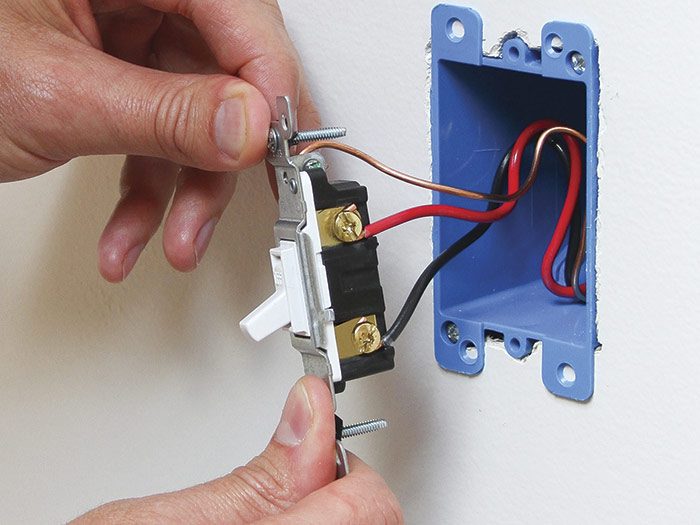

If you are attaching switch wires to screw terminals, loop the wire ends. Connect the ground wire to the green ground screw 3 on the switch. Next, connect the switch-leg wire (red), and the hot lead (black), which runs back to the fixture 4. Keep looped wire ends snug against the screws as you tighten them down. When all wires are secured, gently fold them into the box 5, screw the switch to the box, and install the cover plate.

|

|

|

Excerpted from Wiring Complete, 3rd Edition (The Taunton Press, 2017) by Michael Litchfield and Michael McAlister

Available at Amazon.com.