Choosing the Right Deck Finish

The options for penetrating exterior finishes may seem confusing, but there are some clues to help you choose.

Some species of wood deck planks last many years outside without a finish of any kind, but I guarantee the results won’t be pretty. Sunlight and moisture take their toll, turning the delicate colors and textures of unprotected wood into something gray, checked, and fuzzy. For those of us with wood decks (still the majority of decks being built, by the way), choosing the right protective finish is crucial.

It shouldn’t be too hard, right? A quick walk down the paint aisle at the home center may change your mind on that. To be fair, some manufacturers still take mercy on the consumer who’s used to seeing labels that simply say “oil-based” or “water-based” deck stain. Now, though, we also have alkyd, acrylic, and alkyd/acrylic finishes, among others. There are cans that say “penetrating oil formula,” but they’re on a product that can be cleaned up with soap and water. I even saw one exterior-stain product labeled as “oil-latex.”

In some cases, you’ll also see a complicated string of buzzwords, as on Behr’s Premium Wood-Toned Weatherproofing Wood Finish or Olympic’s Wood Protector Toner Waterproofing Sealant. Then, formulation aside, you also have to choose the level of opacity. This ranges from water clear to opaque, with various shades in between, each offering its own contribution to durability.

It’s true that the exterior-deck-finishes market is complicated, but once you sort through the options, there are fundamental differences separating one finish from the next in terms of application, durability, and cost.

Meet Your Enemies

Besides enhancing a deck’s aesthetic appeal, a protective finish must defend against water and sunlight. Make no mistake that these two elements are among the most destructive forces in nature’s arsenal, and in many climates, they are at work on a day-to-day basis.

Sunlight

When someone talks about wood being damaged by sunlight, they’re really talking about damage from ultraviolet (UV) rays. Wood is essentially a combination of cellulose fibers and lignin, the glue that holds together those fibers. UV light is especially good at destroying lignin, and as that happens, the cellulose fibers loosen and wear away. This exposes a fresh layer of fibers and lignin, and the process repeats.

To be effective, a deck finish either must reflect or absorb this harmful UV light. This applied protection, though, sits on the top layer of the wood, where it’s susceptible to wear and tear. Reapplication—as often as once a year—is usually necessary. If you go without reapplication for too long, you will be staining only the cellulose fibers that are soon to slough off. That’s why lightly sanding an old deck before refinishing is best practice.

Water

Wooden deck planks come from trees, and trees love water. They suck it up at any opportunity. As wood takes on water, it expands across its width (perpendicular to the direction of the grain). As it dries, it shrinks. The cycle will be slower in dense decking (such as ipé) than in soft decking (such as cedar).

Decks in many parts of the country are exposed to frequent wetting and drying cycles. Board ends are most susceptible to this expansion and shrinkage, which is why you often see small cracks at these areas. More cracks mean more water absorption, and the cycle continues.

Penetrating deck finishes aren’t designed to waterproof a board completely, but rather to slow the wetting and drying so that the wood is less likely to develop cracks from dramatic swings in moisture content. Coating the ends of each board with finish is an essential part of sealing a deck.

The moisture level is also a factor in the growth of fungus on deck planks. Finish manufacturers typically keep this maintenance headache under control with the help of mildewcide additives.

You can keep the mildew under control with an additive that’s mixed directly into your deck finish. That way you can look for one with the features you want, such as the right formulation and opacity, while still protecting your deck from moisture issues. Zinsser offers the ADD-2 PREVENT MILDEW additive, as does I-WOOD-CARE.

Which deck finish is best? There’s no easy answer

It would be nice to single out one type of deck finish as the best. Unfortunately, when it comes to preserving wood in such a torturous environment, there’s no such thing as best. No matter which finish you choose, you are faced with trade-offs. It’s also nearly impossible to make concrete statements about Brand X being better than Brand Y, about oil-based finishes being better than water-based, and so on. There are, however, some key points of differentiation between products and some clues to help you navigate the deck-stain market.

Formulation

Oil-Based

AKA: oil, linseed, alkyd

Oil finishes are the traditional option for decks, although their composition has evolved somewhat from old linseed-oil formulations. Linseed oil is still used, but it’s most often combined with alkyds, a synthetic alternative that better resists yellowing. In general, oil-based finishes penetrate wood better than water-based finishes do, and they are easier to recoat. However, they carry the trade-offs of higher VOCs and a cleanup process that requires solvents.

Deck finishes break down into three groups: oil-based, water-based, and hybrid. In a perfect world, these words would be the ones you’d see on the label. In the real world, though, you’re more likely to see mention of “alkyd,“ “acrylic,” or another chemical keyword. Sometimes you don’t even get this clue, just generic wording like “water proofing wood finish,” “deck and siding stain,” or “waterproofer plus clear wood protector.” Knowing some indicator words will help you to sort through the options (see below). When in doubt, the cleanup instructions on the back of the can will tell you at least whether the finish is water- or solvent-based.

VOCs

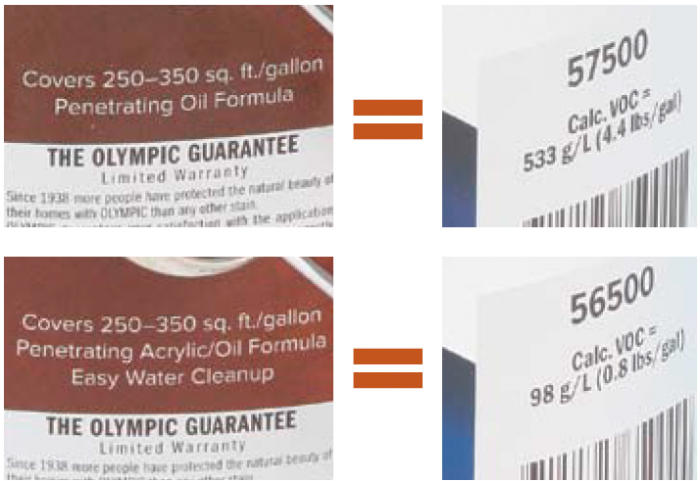

Traditional penetrating finishes rely on a solvent, such as mineral spirits, to help deck planks absorb modified oil resins and other additives. These oil-based finishes are still widely available, but the push now is toward water-based finishes that contain lower amounts of volatile organic compounds (VOCs).

The trend is due in part to stricter government regulations of VOCs, which are a principal ingredient of smog. The nationwide standard for VOCs is 550 grams per liter (g/l), but VOCs in many exterior finishes are limited further by local regulations. In many cases, a manufacturer may offer the same finish in several VOC levels, or simply not offer a product in certain markets because it’s not cost-effective to reformulate products or offer multiple options. In some cases, however, you may find multiple VOC options within the same market, leaving the decision to you. In all cases, the VOC information for a finish is listed on the label, typically near the UPC code or somewhere in the fine print on the back of the can.

To comply with local VOC regulations, some companies offer the same product in different formulations.

For example, though the labels are nearly identical, the Olympic Maximum Clear sold in Pennsylvania is oil-based; in Alabama, it’s a hybrid.

Pigment

Although the terminology and number of options vary slightly from brand to brand, deck finishes typically are available in four levels of opacity: clear, toner, semisolid or semitransparent, and solid. The difference is in the amount of pigment, and it’s the pigment that provides protection against UV damage.

Solid

Solid stains offer the best protection against UV degradation, so all other factors being equal, they last the longest. They are also a good choice if you need to conceal a severely weathered deck. Pigments don’t absorb into wood, though, so these stains essentially sit atop the surface of the wood, which creates a number of potential drawbacks. First, this makes the stain vulnerable to wear and tear from foot traffic and patio furniture. Second, the grain and the color of the underlying wood are obscured. Finally, if water gets below the finish (either from the top side or by being drawn up from below), there is a higher likelihood that the finish will peel.

Expect warranties to range from five to ten years.

Semisolid and Semitransparent

Some companies offer both semitransparent and semisolid options; others offer one or the other. In general, semisolids and semitransparents offer far more color options than toners, and they are the best protection you can get while still retaining some visibility of the underlying wood. These finishes also may be a good choice if you’re trying to renew a weathered deck that doesn’t have dramatic imperfections you’re trying to hide completely.

Expect warranties to range from three to six years.

Toner

Unlike the organic absorbers and stabilizers in a clear finish, toner finishes—sometimes called “wood-toned” or “tinted”—contain inorganic pigments (for example, iron oxides; transparent iron oxides, also called transoxides; and titanium dioxide) that are so finely ground that visible light essentially goes around them. The result is that the color and the grain of the wood appear virtually unaffected, but UV light is blocked. Typically, the colors in this category are wood-toned, such as browns and reds. One perk is that these stains can be matched in color to the wood substrate so that they appear nearly clear even when they’re not.

Expect warranties to range from two to four years.

Solid |

Semisolid |

Semitransparent |

Toner |

Clear, Transparent, Translucent

Low-end clear finishes, which are typically water clear or a milky white that dries clear, offer no UV protection. There are clear finishes that tend toward an amber color; they contain organic UV absorbers and stabilizers. These organic stabilizers, however, break down quickly and leave wood vulnerable to color change and surface damage.

Expect warranties to range from one to four years.

Price

When it comes to paints and finishes, price often can be an indicator of quality, but this rule of thumb really applies only when comparing products from the same company. For instance, Mark Knaebe, a natural-resources specialist at the Forest Products Laboratory, says there are some $25-per-gallon finishes on the market that outperform those costing $40 or $50 per gallon. When comparing different finishes from a single manufacturer, however, price definitely counts.

Behr offers two lines (shown below), a standard and a premium, with a price difference of only about $8. Olympic says its premium clear penetrating finish, called Olympic Maximum (about $32 per gallon) has better-quality ingredients than Olympic WaterGuard ($13.50 per gallon). It’s all about what customers are willing to pay.

|

|

In Conclusion

Try to find a good balance between cost and quality with a deck finish that meets your needs. Consider your environmental conditions, such as whether you have lots of rain or intense sunlight hitting your decking on a regular basis. There’s no one-size-fits-all solution for all homeowners, so take the time to research your options to choose the best one for you.

Justin Fink is a builder-at-large. Scott Gibson contributed to this article. Photos by Rodney Diaz, except where noted.

Click the button below to download a PDF of this article

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Drill Driver/Impact Driver

MicroFoam Nitrile Coated Work Gloves

FastenMaster Screw Bolt Fastening System

View Comments

I recall seeing an article about "oiling" a deck a while back. Doing an internet search resulted in several hits about "Timber Oil" for a deck. Are toners one and the same? I'm familiar with "Danish" oil and Tung oil for furniture. How about "oiling" instead of "staining" a deck and what are the pros and cons?