Installing a Grade Beam

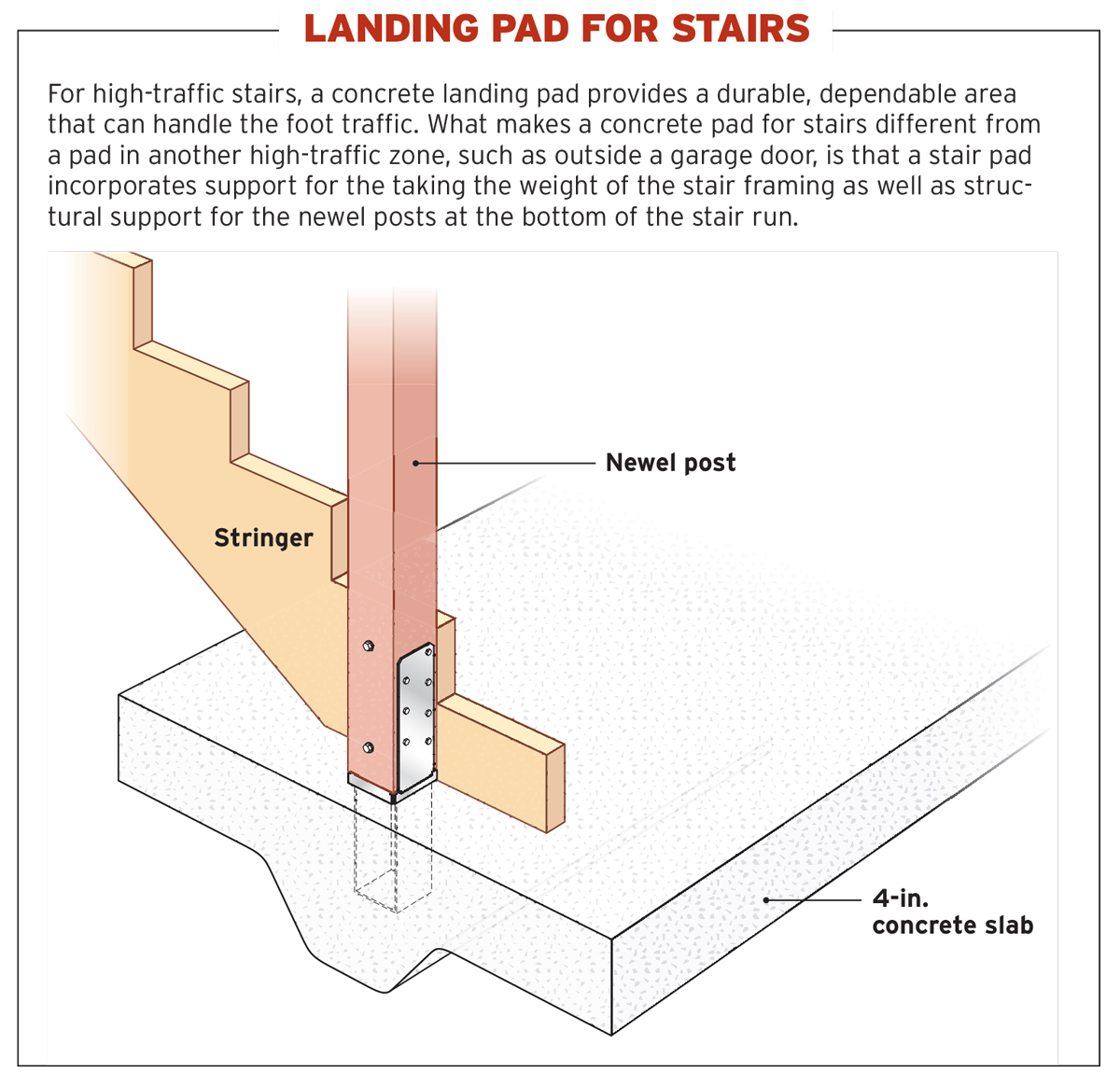

This concrete landing pad at the base of the stairs supports both the weight of the stairs and the posts at the bottom of the run.

There are many situations where a standard footing just won’t do the job. Grade beams and landing pads with integral footings are two ways to upgrade a footing’s appearance. There are also off-the-shelf footing forms, form additions, and concrete reinforcements that are readily available at home stores. For multistory decks, decks that support hot tubs, and decks on a severe slope, the footings may need to be drawn by a certified architect or engineer. And if you live in a cold climate and your deck is connected to the house, you will have to make sure the concrete extends down below the frost depth.

A good option for support at the base of a stairs is to install a grade beam, which is essentially a short foundation wall that supports both newel posts and the weight of the stairs. The main advantage of a grade beam is its low profile. It’s easily hidden under the bottom step, so, while the stairs are fully supported, you can incorporate the landscaping you want. For example, you could install grass or gravel flush to the bottom riser. Or at a later date you could install a landing pad independent of the stair support.

Building the form

A method we have found works well is to align the form in its final position, and then use that to locate where to dig. To do this, cut the stringers with the appropriate rise and run and then temporarily secure them in their final location. With the method shown in the photos below, we let the soil constrain the concrete for the majority of the grade beam and form only the top few inches. Depending on the soil quality for your particular project, you may have to excavate a larger area and extend the form sides down the full height of the grade beam.

If you want the finished riser to conceal the concrete, use the front of the rough stringer to align the inside, front form board. Using steel stakes to secure the form is a big advantage over wooden stakes cut on the spot because they have a relatively small diameter, which will displace less soil, making them easier to drive. Also, the tip of the stake is in line with the shaft, unlike a roughly cut stake where the point may be off center. These two factors make it much easier to drive a steel stake straight down. Assemble the form using the stakes to hold the boards in position.

Trade secretWhen positioning the forms and stakes, align the stakes and form tops flush to the top of the finished concrete height. When the form is positioned after excavation there will be an easy place to register to location and the tops of the stakes won’t get in the way when you’re finishing the concrete. |

A small form like the one shown in the photos does not need to resist much pressure from the weight of the concrete. However, as the form size increases, the weight of the concrete will put a surprising amount of pressure on the form and can easily blow out poorly fastened joints or form boards. When securing the form sides, consider the direction the concrete will push. Because the grade beam is hidden in front and must stop before the first riser, add volume to the back and depth of the concrete to gain the adequate size to support the stairs. Once you’re satisfied with the form, mark the outside with marking spray, which leaves a reference line for excavating the footing. If you mark the inside, you would remove the reference line as you dig.

2. Align the front of the form with the leading edge of the stair stringer to ensure that the grade beam will be hidden.

3. Install stakes on the outside of the form to hold the front form board in place.

4. Place all the form boards to complete the form perimeter. In this case, only three boards were needed.

5. Secure the form parts with 3-in. screws.

6. Double-check to make sure that the form is aligned correctly when the form stakes are installed.

7. Spray the ground to indicate the outside perimeter of the form boards.

8. Excavate the dirt from the foundation footprint. Leave the marked line to use as a reference while digging.

Pouring the grade beam

As with a typical footing, the depth of a grade beam must extend below the frost depth plus a couple inches to allow room for drainage gravel at the bottom. On this project, we used a very coarse drainage gravel left over from another project, so using a soil tamper was a better choice than trying to stomp the gravel down (see step-by-step in photos below). A simple rebar frame will add considerable strength to the concrete. To estimate the length, place the rebar in the excavated trench and eyeball a cut 4 in. shorter than the trench. Use an angle grinder fitted with an abrasive blade to make the cut. Then cut vertical rebar sections a couple of inches shorter than the overall grade-beam depth and hold the frame together with rebar wire ties. For a single grade beam, you’ll want to prepare concrete bag mix in a wheelbarrow adjacent to the site. Add a few inches of mixed concrete to the trench and tap the rebar into position. Avoid sinking the vertical rebar legs into the soil as this may provide a pathway for rust, eventually weakening the overall structure. Mix and add more concrete, being sure to agitate the mix to eliminate any air pockets.

When the concrete is near grade, place the form in position by aligning the form’s top with the steel stakes. At this point, it’s a good idea to place a stringer in position to fine-tune the grade beam’s alignment. Also level the form’s top while securing the form to the stakes to ensure the form doesn’t shift out of position. With the form secure, fill concrete to the top, remembering to agitate the mix. Using the form to guide the float, smooth the top of the grade beam to a rough finish.

9. Dig down 2 in. below frost depth as determined by your local building department.

10. Add and compact 2 in. of drainage gravel at the bottom of the footing to help prevent frost heave.

11. Cut lengths of rebar 4 in. shorter than the overall footing length and 2 in. shorter than the overall height.

12. Use rebar ties to connect the rebar frame. For a small footing like this, the exact configuration is not critical.

13. Hand mix the concrete until it has the consistency of thick cottage cheese.

14. Tap the rebar frame into position once there are a few inches of concrete in the footing.

15. Agitate the concrete to eliminate air pockets that could weaken the footing.

16. Place the form in the position established by the steel stakes.

17. Align the top of the form with the top of the stakes. If necessary, use gravel or concrete to hold the form in place.

18. Reposition the stringer; and if necessary, attach supports.

19. Level the form and secure it in place by screwing it to the steel stakes.

20. Fill the form to the top with concrete, agitating the concrete as you progress.

21. Finish the top to your satisfaction. The top needs to be flat, but not pretty.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Standard Marking Chalk

Cepco BoWrench Decking Tool

N95 Respirator