2 Ideas for Custom Railings

Site-built deck rails use unconventional materials to preserve the view.

Synopsis: Factory-built deck-rail systems are available at home centers, but there are advantages to custom designs: They can be cheaper, they can display craft and skill, and they can reflect a homeowner’s taste and style perfectly. Managing editor Debra Judge Silber looks at two custom deck railings, one by Maryland builder Clemens Jellema and one from North Carolina builder Michael Chandler. Jellema’s deck has nautical features, such as a top rail wrapped with marine-grade roping, and tempered-glass balusters that allow views to the nearby woods and river. Chandler’s design features agricultural wire (“goat panels”) instead of traditional balusters and rope lights tucked under the top rails.

While there’s no shortage of off-the-shelf railing systems from decking manufacturers, there still can be advantages to building your own system. Cost is one. Craft is another. Still another is the ability to deliver a unique outdoor feature that fits a client’s desires and a deck’s design perfectly. “It’s a lot more fun to play with different ideas and to create something that’s more than the sum of its parts,” says North Carolina builder Michael Chandler, who incorporated agricultural panels and coil stock in his railing. “There’s an alchemy in taking something very prosaic, like galvanized flashing and goat wire, and turning it into something that’s high value and more attractive than premade cast-aluminium stuff.”

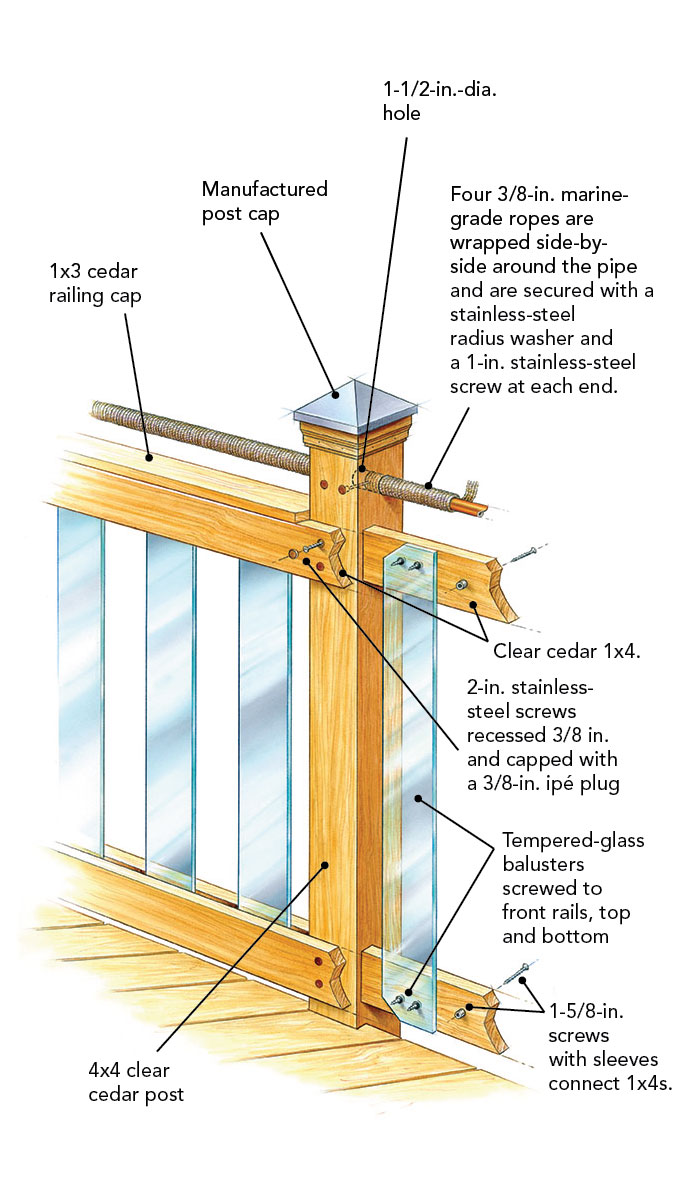

Maryland deck builder Clemens Jellema used two types of manufactured balusters in the railing he designed for a home near the Chesapeake bay, but he supported them in a cedar framework detailed with ipé plugs and a rope-wound top rail. In Jellema’s case, with the high labor costs associated with a metropolitan area, it pays to incorporate some ready-made components.

If you’re inspired by these designs to create your own answer to run-of-the-mill deck rails, we invite you to post photos of your work in our project gallery at FineHomebuilding.com. Consider yourself warned that we’ll be on the lookout for creative deck accessories to feature in our next Decks & Outdoor Projects special issue. And please keep in mind that although the railings shown here meet the code requirements for their jurisdictions, regulations vary, so check the codes in your area.

Nautical details

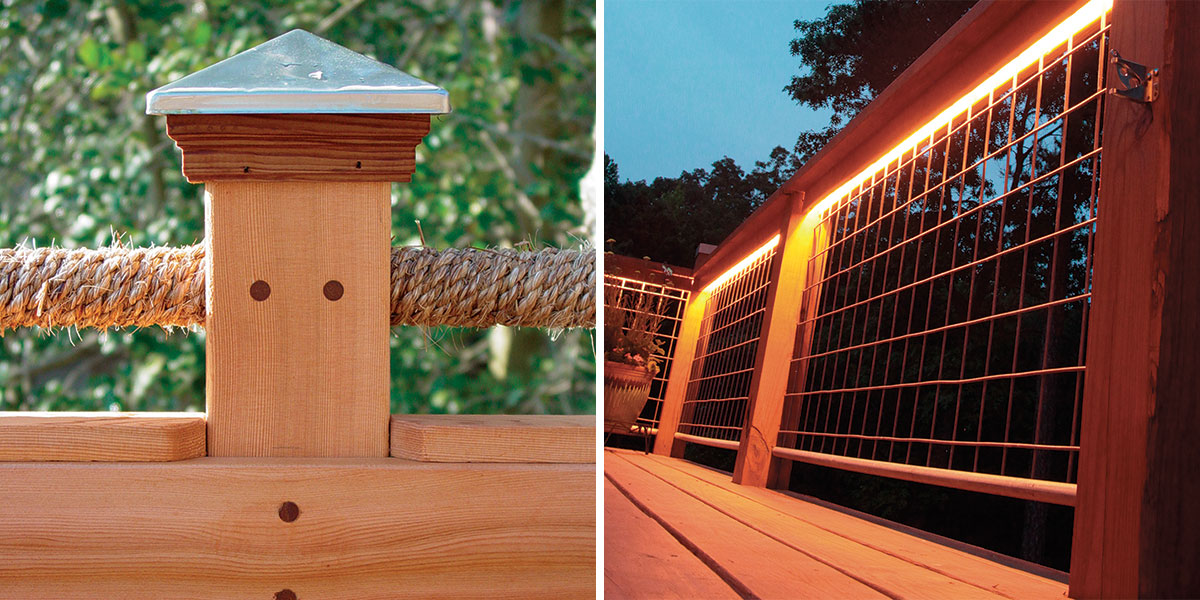

Maryland deck builder Clemens Jellema produced this design for a client who wanted a rail with nautical features that wouldn’t obscure his view of the nearby woods and river. Jellema achieved the shipshape appearance with a top rail of 1-in. copper pipe wrapped with marine-grade roping. To preserve the view, he chose tempered-glass balusters from Deckorators. For the stair rails and deck sections facing the yard, he used the company’s stainless aluminium balusters and connectors. In those sections, a single cedar 2×4 was used for each top and bottom rail.

Cost:

Materials for the glass sections totaled about $50 per lin. ft. (compared to about $42 for the aluminum sections). In both cases, the option of using balusters from a manufacturer outweighed the labor cost of fabricating them. Jellema also estimates the choice of clear cedar rather than STK (select tight knot) added about $6 to $8 per lin. ft.

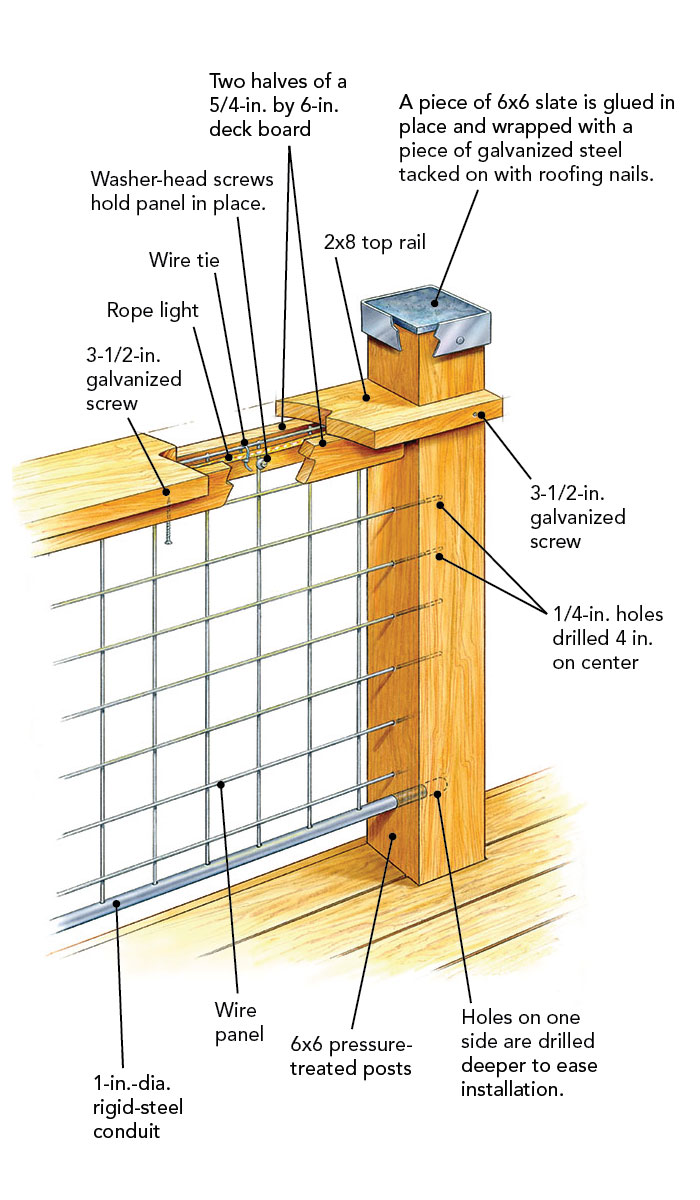

Wire panels for a wide-open view

When budget concerns arose, North Carolina builder Michael Chandler corralled the cost of this 600-sq.-ft. deck project by using agricultural wire goat panels for the guardrails rather than the custom metalwork initially planned. The panels are made of 7/32-in.-dia. wire in a 4-in. grid pattern that’s stiff enough to stand in for traditional balusters. The ends of each panel are inserted in holes drilled into the posts or, along the bottom, in a 1-in.-dia. rigid-steel conduit that serves as the bottom rail. Rope lights tucked under the top rails provide illumination.

Cost:

Materials for the horizontal sections, including the rope light, totaled about $10 per lin. ft. Also known as “feedlot panels,” the wire sections used in this railing are available from agricultural suppliers in 16-ft. by 4-ft. sections for less than $50 apiece.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Jigsaw

4-Gallon Piston Backpack Sprayer

Cepco BoWrench Decking Tool

View Comments

I feel very compelled to advise readers that horizontal wire, fencing, etc is not code compliant here in Canada and may not be elsewhere. It's very dangerous as it allows children to climb and perhaps fall off the raised deck. Shame on FineHomebuilding for featuring these "latest and greatest ideas" without appropriate warnings even if the wire is code compliant.

After extensive research, we went with a commercially available glass baluster system. We are very happy with the unrestricted view with glass balusters. It preserves the view much better than we expected. I am not going to mention the manufacturer's name because we had a lot of problems with them and still have a claim to file against powder coated rails that apparently did not have U/V protection. The rails look awful. The rest of it looks great.

We did look into pig wire and cable railings and even a very nice stainless steel horizontal railing system, but the legal aspects were against those. As far as we could tell, the code did not forbid them (as of about 2013) but California's main industry being lawsuits, we did not want the risk. Besides, it seemed likely that codes would ban them even if they hadn't done so yet.

Here are a couple of things I did learn, though.

1. 1/4" tempered glass is apparently not strong enough to meet the 200# force requirement of a legal 42" high railing. I had to get two pieces custom made and finding a supplier who could make 5/16" pieces was challenging.

2. The system I bought included the sockets for the glass already laid out on the rails. You cut them to fit between posts such that the space at each end is equal. Of course you try to space the posts perfectly, but that doesn't always work out unless you literally framed the deck for this system to begin with.

I put these railings on four different decks and on one of the decks, each end of an L-shaped railing ended up spaced so that it was not possible to install them and make them look good and retain the 4" max spacing. So what I did was have a custom baluster made for each end. These were 5" wide pieces, but the top and bottom were cut down to fit into the factory sockets. If you look at it and think about it, you notice it. But being on the ends, being made of clear glass, and with your eye drawn by the view, they are never noticeable.

In regards to Suburbanguy comments:

You bring up some very good points.

In this case, I think the idea of the article was to provide different railing ideas. I appreciate the time and effort to show different types of rails and the cost.

It should be the owner, designer, builder, etc to be responsible for what meets or does not meet code for their area. Think about the number of readers and different areas Fine Homebuilding is distributed.

Code requirements should always be at the forefront, even when there is no enforcement agency. Decks and railing have had some major building changes. Many of these changes have added additional expense to the price of decks and railings. But the changes have made for safer decks and rails.

Again thanks for the reminder. And kids will climb anything or at least try. There is no cure for stupidity or no parental supervision.

Love the wire panel idea - considering it for our deck. But it seems to me the pipe/conduit at the bottom is in a very rust-prone position (upward-facing holes). Is there an accommodation for it to drain? Thanks!

What about corrosion issues with feedlot panels and pressure treated lumber?